Biomacromolecule microreactor based on protein film isolation and fixation

A biomacromolecule and microreactor technology, applied in the field of biomacromolecule microreactors, can solve problems such as poor biocompatibility, high cost, and complicated preparation methods, and achieve easy operation, low cost, and simple and efficient preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

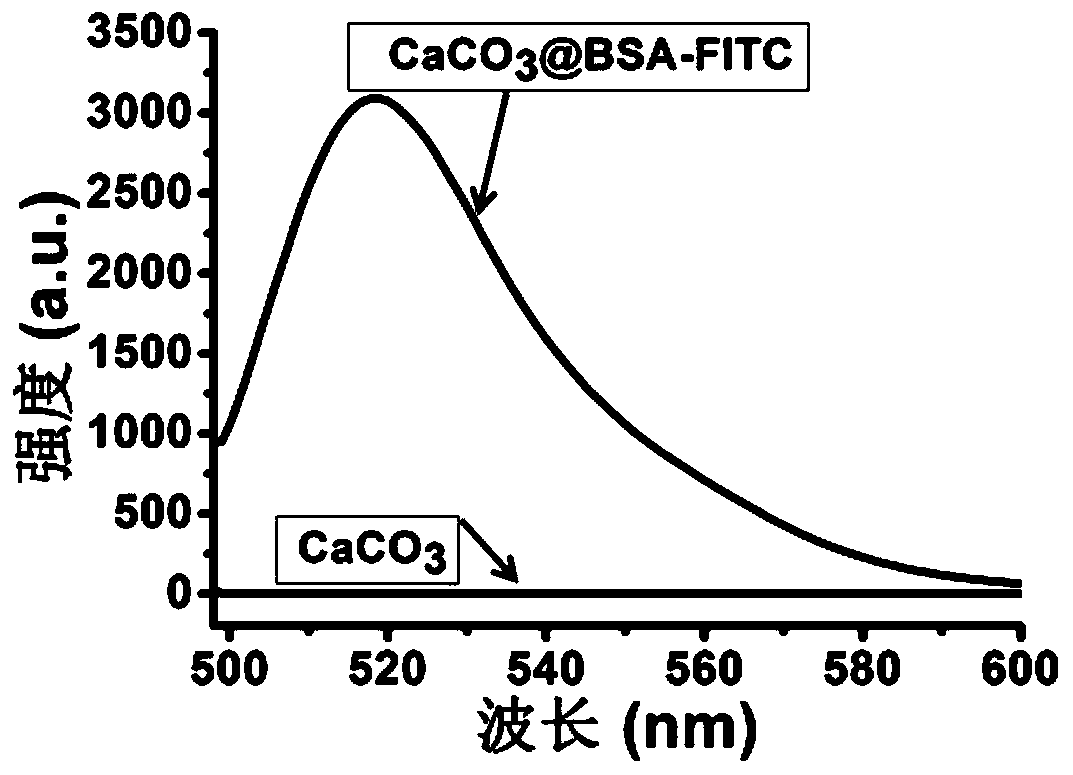

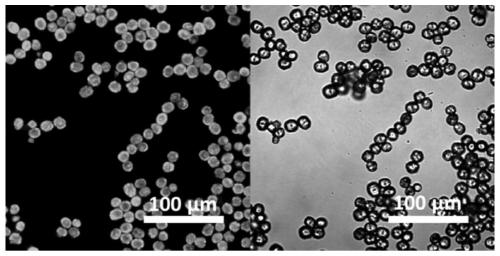

[0036] 1. Prepare 5mL 0.33mol / L Na respectively 2 CO 3 Aqueous solution and 0.33mol / L CaCl 2 aqueous solution, and then 100 μL of 10 mg / mL fluorescently labeled bovine serum albumin aqueous solution was added to the CaCl 2 solution in aqueous solution, then add Na 2 CO 3 Aqueous solution, and kept stirring at 650rpm for 30 seconds, after standing for 5 minutes, centrifuged and washed with deionized water to obtain CaCO with bovine serum albumin loaded inside and on the surface 3 particles. Such as Figure 1~6As shown, CaCO with bovine serum albumin loaded inside and on the surface was successfully prepared 3 particles.

[0037] 2. Adjust 1mL of 10mmol / L tris(2-carboxyethyl)phosphine in PBS buffer to pH 7.0 with NaOH, then mix it with 1mL of 2mg / mL lysozyme in PBS buffer, and add the above preparation Well loaded CaCO with bovine serum albumin 3 Particles were incubated at room temperature for 50 minutes; then the reaction impurities were removed by centrifugation to o...

Embodiment 2

[0040] In step 1 of this embodiment, prepare 5mL 0.33mol / L Na 2 CO 3 Aqueous solution and 0.33mol / L CaCl 2 aqueous solution, then Na 2 CO 3 Aqueous solution was added to CaCl 2 in aqueous solution, and kept stirring at 650rpm for 30 seconds, after standing still for 5 minutes, it was washed by centrifugation with deionized water to obtain CaCO 3 particles. Will get CaCO 3 The particles were dispersed in 100 μL of 10 mg / mL fluorescently labeled bovine serum albumin aqueous solution, and incubated at room temperature for 24 hours to obtain CaCO with bovine serum albumin loaded on the surface. 3 particles, such as Figures 12 to 13 shown. The other steps were the same as in Example 1 to obtain a bovine serum albumin microreactor isolated and fixed by a lysozyme film.

Embodiment 3

[0042] In step 1 of this embodiment, prepare 5mL 0.33mol / L Na 2 CO 3 Aqueous solution and 0.33mol / L CaCl 2 aqueous solution, and then 100 μL of 10 mg / mL fluorescently labeled bovine serum albumin aqueous solution and 100 μL of 10 mg / mL fluorescently labeled human serum albumin aqueous solution were added to CaCl 2 In the solution aqueous solution, other steps are identical with embodiment 1, obtain the microreactor (see Figure 14 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com