Dried spiced guavas and making method and sulfur-free composite spice thereof

The technology of a spiced guava and its production method, which is applied in the field of food processing, can solve the problems of guava, such as poor storage resistance, easy dehydration and wilting of fruit, and decreased fruit hardness, so as to maintain the original nutritional value, increase appetite, and reduce sugar content. little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072]A dry processing method for spiced guava, comprising the following production steps:

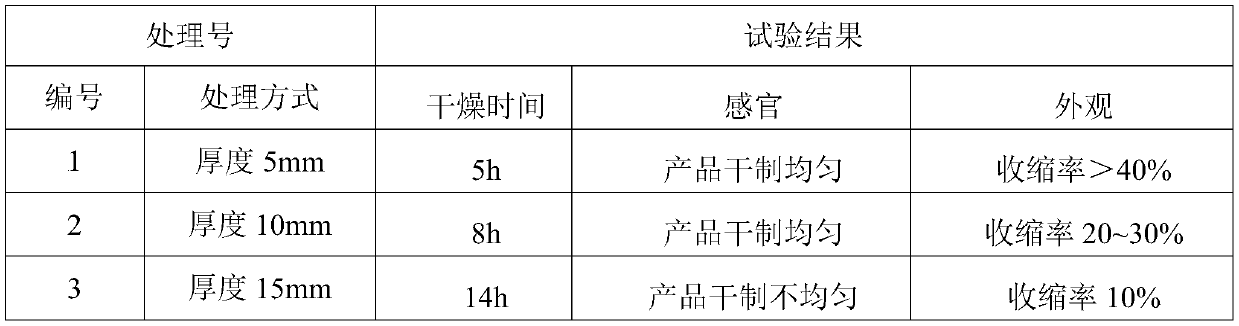

[0073] S1. Wash the guava fruit and cut it into semicircular slices or fan slices with a thickness of 10mm.

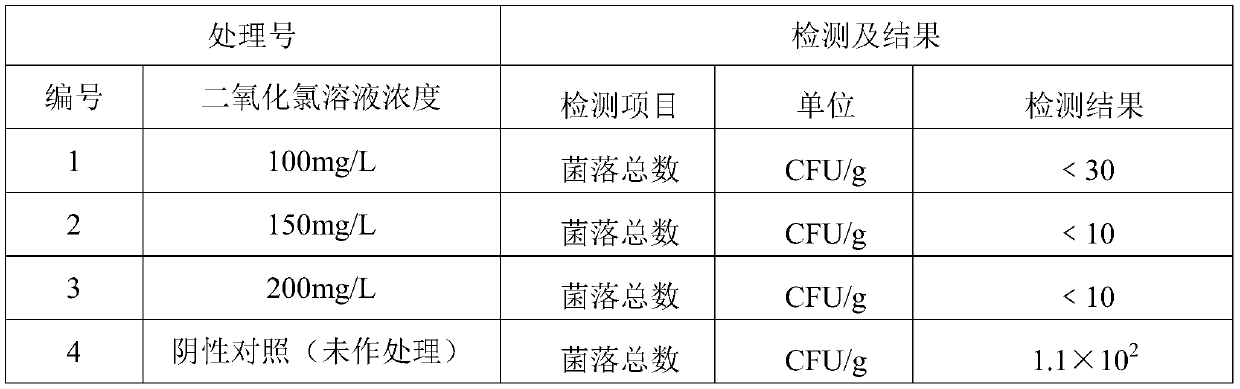

[0074] S2. Soak the cut fruit slices in a chlorine dioxide solution with a mass concentration of 150 mg / L for sterilization.

[0075] S3. Put the sterilized fruit slices in a drying tray, and dry them in an environment of 55-60°C for 8 hours to reduce the water content of the fruit slices to 30%.

[0076] S4. Mix the dried guava fruit slices with the sulfur-free compound five-spice liquid at 40-45°C in a mass ratio of 1:0.6, stir well, and stir once every 30 minutes. After the fruit slices fully absorb the sulfur-free compound five-spice liquid, stop stirring , the time is about 2h.

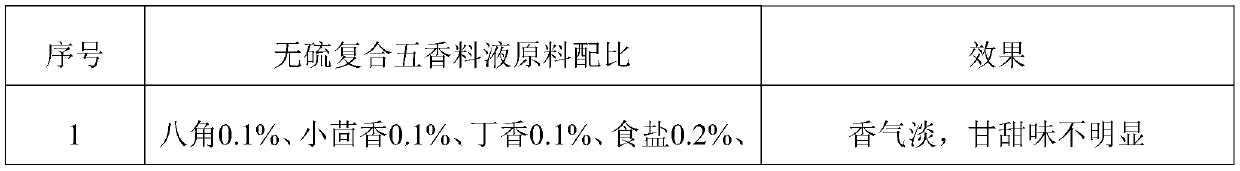

[0077] The sulfur-free compound five-spice liquid is composed of components according to the mass ratio: malic acid 0.1%, star anise 0.3%, cumin 0.5%, clove 0.5%, salt 0.5%, β-cyclodextrin 1%, l...

Embodiment 2

[0081] A dry processing method of spicy spiced guava, comprising the following production steps:

[0082] S1. Wash the guava fruit and cut it into semicircular slices or fan slices with a thickness of 10mm.

[0083] S2. Soak the cut fruit slices in a chlorine dioxide solution with a mass concentration of 150 mg / L for sterilization.

[0084] S3. Put the sterilized fruit slices in a drying tray, and dry them in an environment of 55-60°C for 8 hours to reduce the water content of the fruit slices to 30%.

[0085] S4. Mix the dried guava fruit slices with the sulfur-free compound five-spice liquid at 40-45°C in a mass ratio of 1:0.6, stir well, and stir once every 30 minutes. After the fruit slices fully absorb the sulfur-free compound five-spice liquid, stop stirring , the time is about 2h.

[0086] The sulfur-free compound five-spice liquid is composed of components according to the mass ratio: malic acid 0.1%, star anise 0.3%, cumin 0.5%, cloves 0.5%, salt 0.5%, dried red pep...

Embodiment 3

[0090] A salt and pepper spiced guava dry processing method, comprising the following production steps:

[0091] S1. Wash the guava fruit and cut it into semicircular slices or fan slices with a thickness of 10mm.

[0092] S2. Soak the cut fruit slices in a chlorine dioxide solution with a mass concentration of 150 mg / L for sterilization.

[0093] S3. Put the sterilized fruit slices in a drying tray, and dry them in an environment of 55-60°C for 8 hours to reduce the water content of the fruit slices to 30%.

[0094] S4. Mix the dried guava fruit slices with the sulfur-free compound five-spice liquid at 40-45°C in a mass ratio of 1:0.6, stir well, and stir once every 30 minutes. After the fruit slices fully absorb the sulfur-free compound five-spice liquid, stop stirring , the time is about 2h.

[0095] The sulfur-free compound five-spice liquid is composed of components according to the mass ratio: 0.1% malic acid, 0.3% star anise, 0.5% fennel, 0.5% clove, 0.2% salt, 1% β-c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com