Concrete water reducing agent and preparation method thereof

A concrete water-reducing agent and water-reducing type technology, applied in the field of concrete water-reducing agent, can solve the problems of high energy consumption and complicated preparation, and achieve the effects of simple preparation, reduced energy consumption and good slump retention.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A concrete water reducing agent, composed of HPEG water-reducing monomer, TPEG slump-retaining monomer, mercaptopropionic acid, sodium hypophosphite, acrylic acid, hydroxyethyl acrylate, maleic anhydride, vitamin C, liquid alkali NAOH, hydrogen peroxide , dextrin, APS ammonium persulfate, and deionized water, and its components are calculated by weight: 60 parts of HPEG water-reducing monomer, 60 parts of TPEG slump-preserving monomer, 1 part of mercaptopropionic acid, hypophosphorous acid 1 part of sodium, 30 parts of acrylic acid, 30 parts of hydroxyethyl acrylate, 40 parts of maleic anhydride, 30 parts of vitamin C, 10 parts of liquid caustic soda NAOH, 4 parts of hydrogen peroxide, 20 parts of dextrin, 30 parts of APS ammonium persulfate, 50 parts of deionized water share.

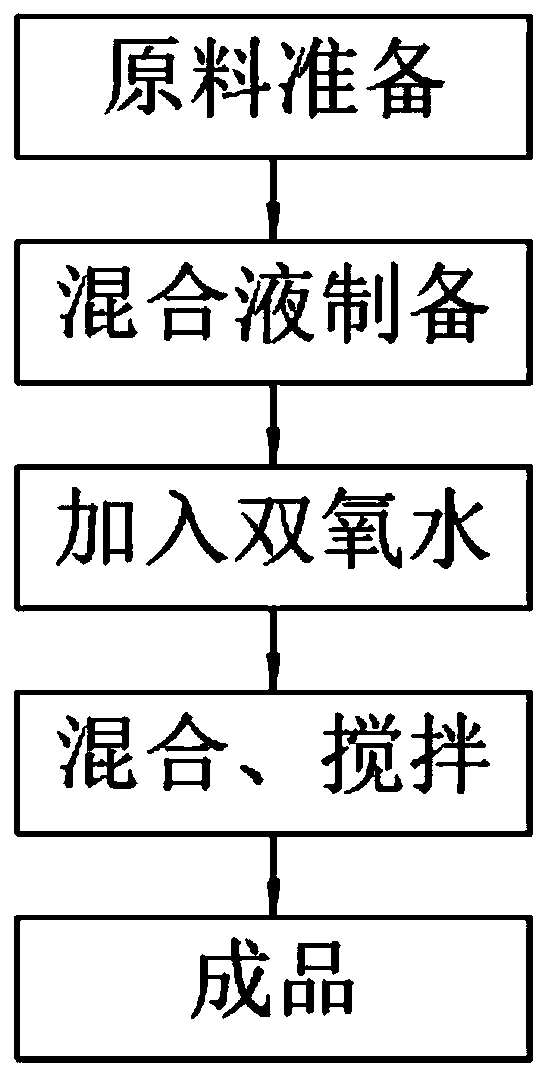

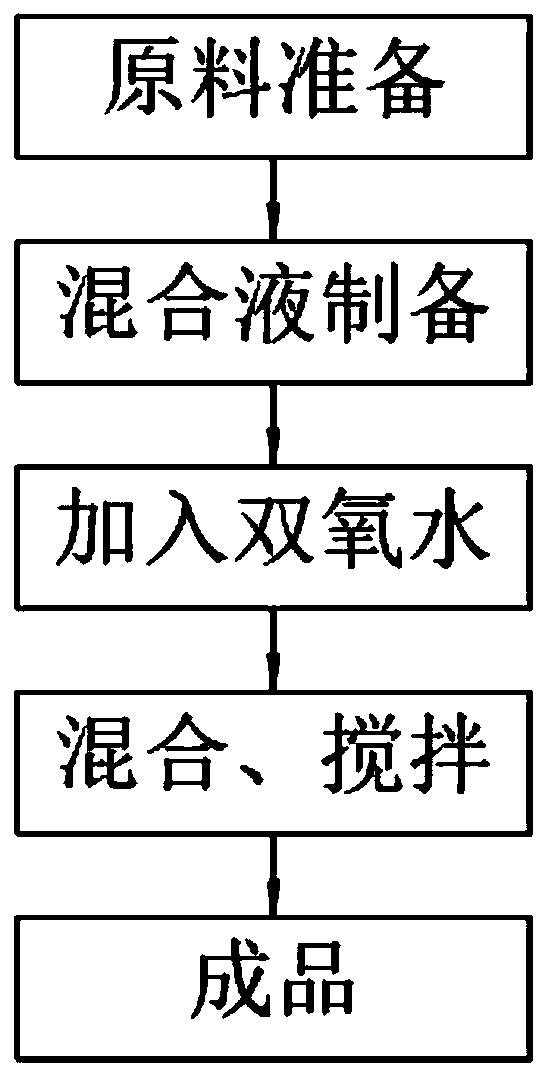

[0025] A preparation method of concrete water reducer, comprising the steps of:

[0026] Step 1: Raw material preparation: 60 parts of HPEG water-reducing monomer, 60 parts of TPEG slump-proof ...

Embodiment 2

[0032] A concrete water reducing agent, composed of HPEG water-reducing monomer, TPEG slump-retaining monomer, mercaptopropionic acid, sodium hypophosphite, acrylic acid, hydroxyethyl acrylate, maleic anhydride, vitamin C, liquid alkali NAOH, hydrogen peroxide , dextrin, APS ammonium persulfate, deionized water, its components are calculated by weight: 70 parts of HPEG water-reducing monomer, 70 parts of TPEG slump-preserving monomer, 2 parts of mercaptopropionic acid, hypophosphorous acid 2 parts of sodium, 35 parts of acrylic acid, 35 parts of hydroxyethyl acrylate, 45 parts of maleic anhydride, 35 parts of vitamin C, 15 parts of liquid caustic soda NAOH, 5 parts of hydrogen peroxide, 25 parts of dextrin, 35 parts of APS ammonium persulfate, 55 parts of deionized water share.

[0033] A preparation method of concrete water reducer, comprising the steps of:

[0034] Step 1: Raw material preparation: 70 parts of HPEG water-reducing monomer, 70 parts of TPEG slump-proof monome...

Embodiment 3

[0040] A concrete water reducing agent, composed of HPEG water-reducing monomer, TPEG slump-retaining monomer, mercaptopropionic acid, sodium hypophosphite, acrylic acid, hydroxyethyl acrylate, maleic anhydride, vitamin C, liquid alkali NAOH, hydrogen peroxide , dextrin, APS ammonium persulfate, deionized water, its components are calculated by weight: 80 parts of HPEG water-reducing monomer, 80 parts of TPEG slump-preserving monomer, 3 parts of mercaptopropionic acid, hypophosphorous acid 3 parts of sodium, 40 parts of acrylic acid, 40 parts of hydroxyethyl acrylate, 50 parts of maleic anhydride, 40 parts of vitamin C, 20 parts of liquid caustic soda NAOH, 6 parts of hydrogen peroxide, 30 parts of dextrin, 40 parts of APS ammonium persulfate, 60 parts of deionized water share.

[0041] A preparation method of concrete water reducer, comprising the steps of:

[0042] Step 1: Raw material preparation: 80 parts of HPEG water-reducing monomer, 80 parts of TPEG slump-proof monome...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com