High-pumping LC15 ceramsite concrete and preparation method thereof

A high pumping technology of ceramsite concrete, which is applied in the field of building materials, can solve problems such as rushing to the front end of the pump pipe or blockage at the elbow, easy floating of ceramsite, delamination, segregation, and influence on the performance of the mixture. Improves compressive strength, improves workability and water retention, and prevents floating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1-3

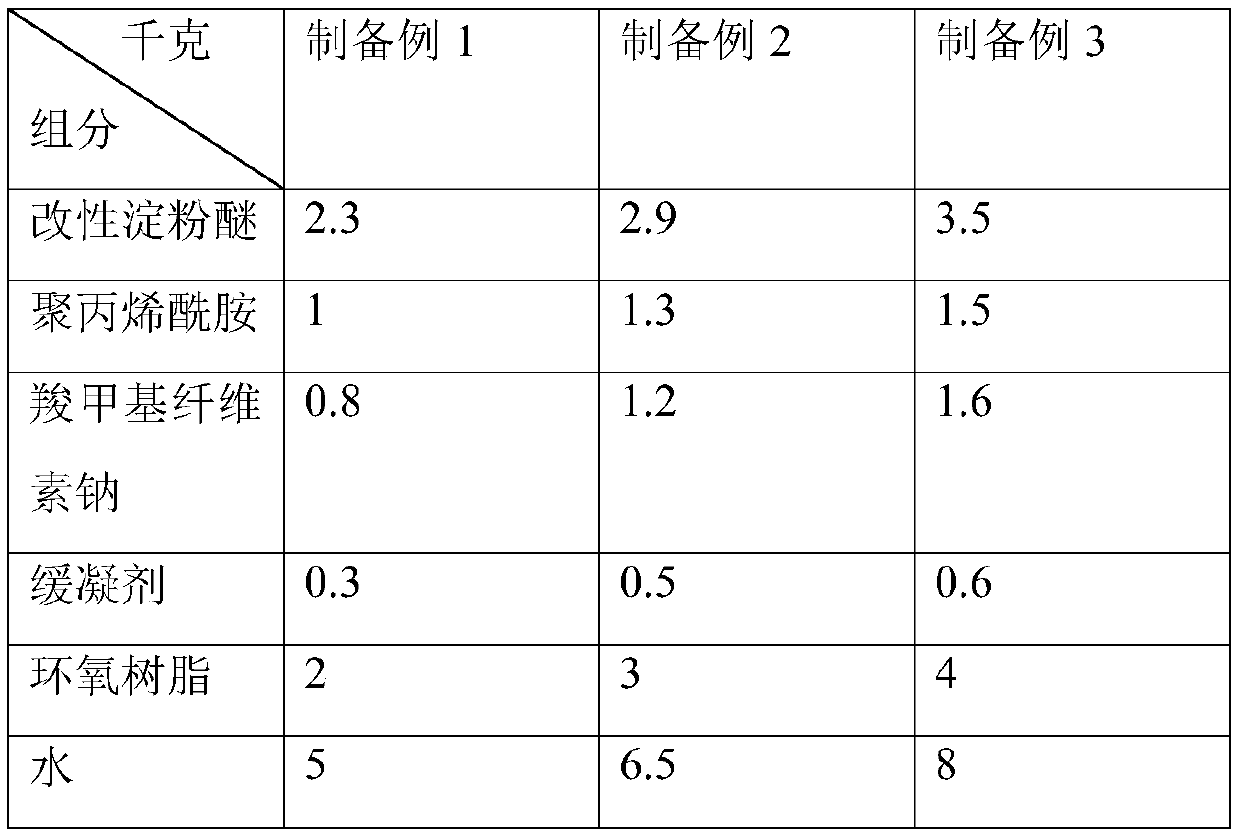

[0037] In the preparation example 1-3, the epoxy resin is selected from the epoxy resin of E-44 sold by Guangzhou Gongying Chemical Co., Ltd., and the polyacrylamide is selected from the model FQ-XA sold by Gongyi Tenglong Water Treatment Materials Co., Ltd. The polyacrylamide and modified starch ether are selected from the modified starch ether of model S301 sold by Shanghai Shuoshi Chemical Co., Ltd., and the lignocellulose is selected from the lignocellulose and polyester of model C2800 sold by Langfang Guyuan Building Materials Technology Co., Ltd. The succinimide is selected from the polysuccinimide sold by Shandong Yuanlian Chemical Co., Ltd. with the model number PSI.

preparation example 1

[0038] Preparation Example 1: According to the ratio of raw materials in Table 1, 2kg of epoxy resin was added to 5kg of water, stirred at a speed of 2000r / min for 20min to form an epoxy resin emulsion, and 1kg of polyacrylamide was added to the ring in 2 times. In the epoxy resin emulsion, stir at a rotating speed of 500r / min. After mixing evenly, add 2.3kg modified starch ether, 0.8kg carboxymethyl cellulose sodium and 0.3kg retarder, mix evenly, and the granules of modified starch ether The diameter is 200μm, and the retarder is made by mixing the following components: 1.2kg sodium phosphate, 2.1kg lignin fiber, 1.6kg sodium gluconate and 0.7kg polysuccinimide.

[0039] The raw material ratio of pumping agent in table 1 preparation example 1-3

[0040]

preparation example 2

[0041] Preparation Example 2: According to the ratio of raw materials in Table 1, add 3kg of epoxy resin to 6.5kg of water, stir at a speed of 2500r / min for 25min to form an epoxy resin emulsion, add 1.3kg of polyacrylamide in 3 times Add 2.9kg of modified starch ether, 1.2kg of carboxymethyl cellulose sodium and 0.5kg of retarder to the epoxy resin emulsion, stir at a speed of 650r / min, and mix evenly. The particle size is 250μm, and the retarder is made by mixing the following components: 1.6kg sodium phosphate, 2.4kg lignin fiber, 1.7kg sodium gluconate and 0.9kg polysuccinimide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com