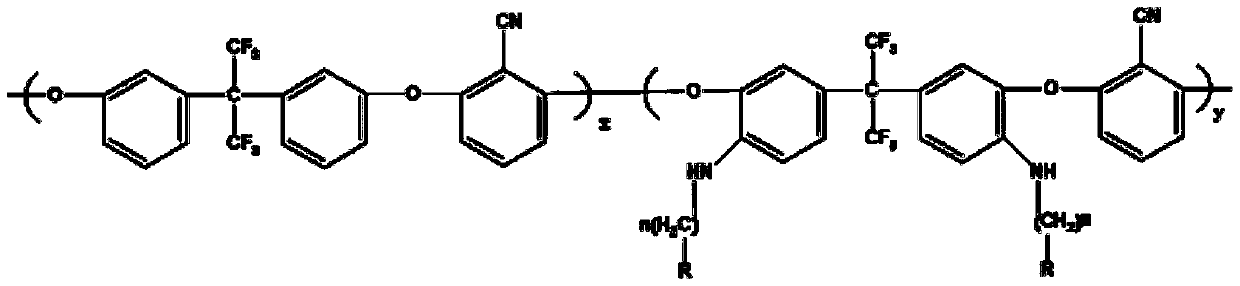

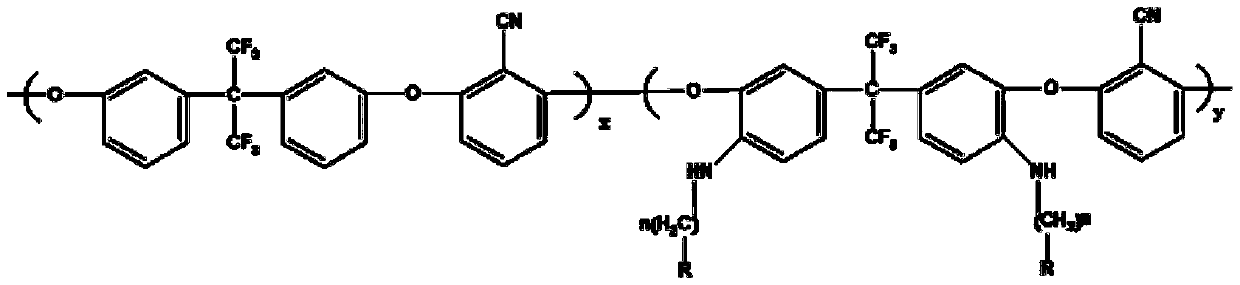

Long-chain branched poly(arylene ether nitrile) anion exchange membrane and preparation method thereof

A technology of anion exchange membrane and polyarylether nitrile, which is applied in the field of long-chain branched polyarylether nitrile anion exchange membrane and its preparation, can solve the problems of low hydroxide ion conductivity, poor membrane dimensional stability, and poor alkaline stability. Advanced problems, achieve a wide range of solvent selection, promote microphase separation, and simple reaction steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

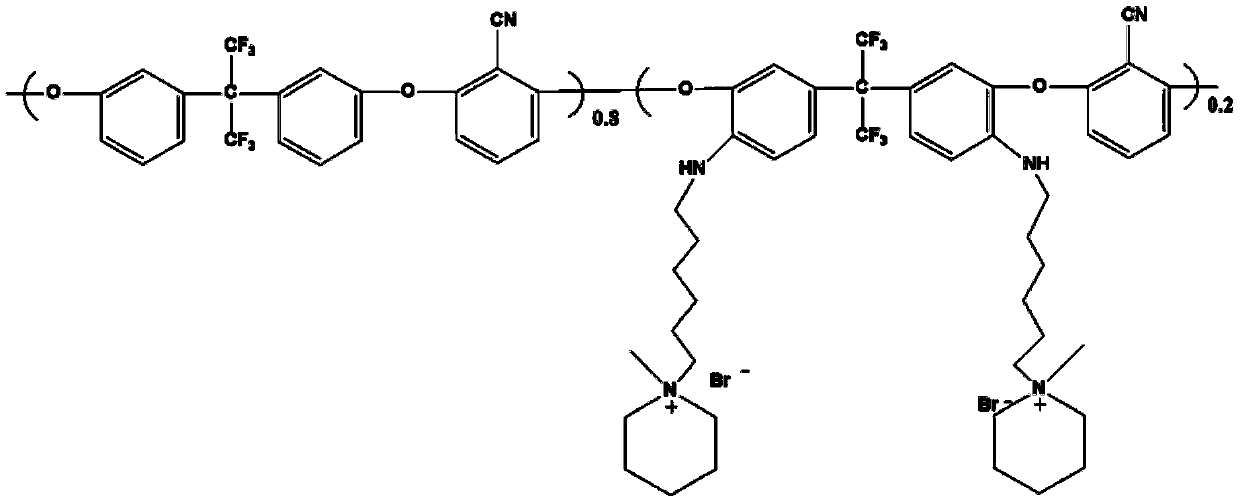

Embodiment 1

[0041] The synthesis of polyarylether nitrile: 2,6-difluorobenzonitrile, 0.7475g (2mmol) of 1.4050g (10mmol) 2,2-bis(3-amino-4-hydroxyl phenyl) hexafluoropropane, 2.7447 g (8mmol) of hexafluorobisphenol A and 1.3961g (10mmol) of potassium carbonate were added to a 50mL three-necked flask, then 5mL of toluene and 9mL of N,N-dimethylacetamide were added to form a mixed solution, and the mixture was prepared in a protective gas atmosphere. Gradually raise the temperature to 140°C, cool and reflux for about 4 hours until the water is completely removed, and then continue to heat up to 160°C for about 15 hours. After the reaction is completed, the product is slowly poured into the ethanol solution under mechanical stirring, and the filamentous polymer product is precipitated. Then, in order to further improve the purity of the product, a re-precipitation operation is carried out, that is, the obtained filamentous product is redissolved in N,N- In dimethylacetamide, it is prepared i...

Embodiment 2

[0047] The synthesis of polyarylether nitrile: 2,6-difluorobenzonitrile, 0.7475g (2mmol) of 1.4050g (10mmol) 2,2-bis(3-amino-4-hydroxyl phenyl) hexafluoropropane, 2.7447 g (8mmol) of hexafluorobisphenol A and 1.3961g (10mmol) of potassium carbonate were added to a 50mL three-necked flask, then 5mL of toluene and 9mL of N,N-dimethylacetamide were added to form a mixed solution, and the mixture was prepared in a protective gas atmosphere. Gradually raise the temperature to 140°C, cool and reflux for about 4 hours until the water is completely removed, and then continue to heat up to 160°C for about 15 hours. After the reaction is completed, the product is slowly poured into the ethanol solution under mechanical stirring, and the filamentous polymer product is precipitated. Then, in order to further improve the purity of the product, a re-precipitation operation is carried out, that is, the obtained filamentous product is redissolved in N,N- In dimethylacetamide, it is prepared i...

Embodiment 3

[0053] The synthesis of polyarylether nitrile: 1.4050g (10mmol) of 2,6-difluorobenzonitrile, 1.495g (4mmol) of 2,2-bis(3-amino-4-hydroxyphenyl)hexafluoropropane, 2.0585 g (6mmol) of hexafluorobisphenol A and 1.3961g (10mmol) of potassium carbonate were added to a 50mL three-necked flask, and then 5mL of toluene and 9mL of N,N-dimethylacetamide were added to form a mixed solution. Gradually raise the temperature to 140°C, cool and reflux for about 4 hours until the water is completely removed, and then continue to heat up to 160°C for about 15 hours. After the reaction is completed, the product is slowly poured into the ethanol solution under mechanical stirring, and the filamentous polymer product is precipitated. Then, in order to further improve the purity of the product, a re-precipitation operation is carried out, that is, the obtained filamentous product is redissolved in N,N- In dimethylacetamide, it is prepared into a solution with a mass concentration of 100g / L, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ionic conductivity | aaaaa | aaaaa |

| Ionic conductivity | aaaaa | aaaaa |

| Ionic conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com