A kind of preparation method of aviation kerosene or diesel oil

A technology of aviation kerosene and diesel oil, which is applied in the field of preparation of aviation kerosene or diesel oil, and can solve problems such as complex process, limited raw materials, and inability to be directly used as engine fuel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] Preparation of protonated ionic liquid: Taking the synthesis of ethanolamine acetate as an example, add 6.1g of ethanolamine into two-necked flasks, one of which is inserted into a thermometer to control the temperature of the system, and the other is equipped with a constant-pressure dropping funnel filled with 6.0g of acetic acid , put the above device into an ice-water bath, add acetic acid dropwise to ethanolamine under stirring, and maintain the temperature of the system between 0-10°C with an ice-water bath. After the dropwise addition, the mixture was stirred at room temperature for 24 hours, dried in vacuum at 60°C, sealed and stored for future use, labeled as ethanolamine acetate. The synthesis process and naming method of other protonated ionic liquids are consistent with the above process. When the acid used is hydrochloric acid and / or nitric acid, it is necessary to perform rotary evaporation to remove water after stirring, and then perform vacuum drying at 6...

Embodiment

[0044] 1 Preparation of aviation kerosene precursor

[0045] The preparation method of the aviation kerosene precursor is consistent with the aldol condensation reaction process of 2-methylbenzaldehyde and cyclohexanone described above, and the details of the differences are shown in Table 1.

[0046] Table 1. Aldol condensation reactions and their results

[0047]

[0048]

[0049]

[0050] From the gas chromatographic yield of the target product given by Examples 1-57 in Table 1, it can be seen that there is a certain yield of product under the action of different protonated ionic liquids; wherein ethanolamine acetate The effect is the best; when ethanolamine acetate is used as the catalyst, the substrate can be extended to other lignocellulosic aldehydes and cellulose ketones, and the catalytic effect is still good; it shows that the system has certain universality ;

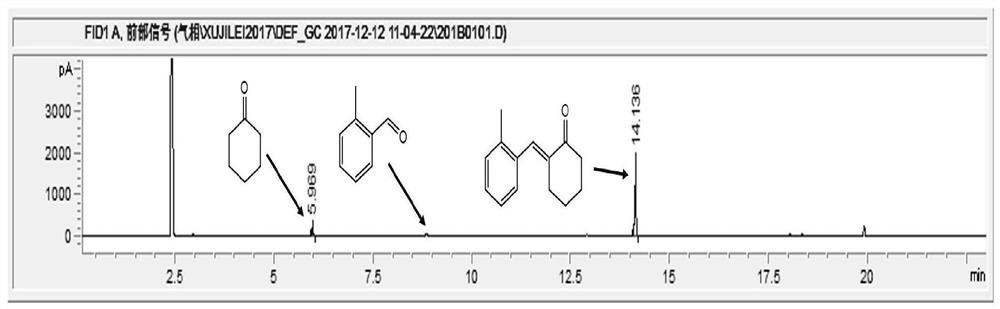

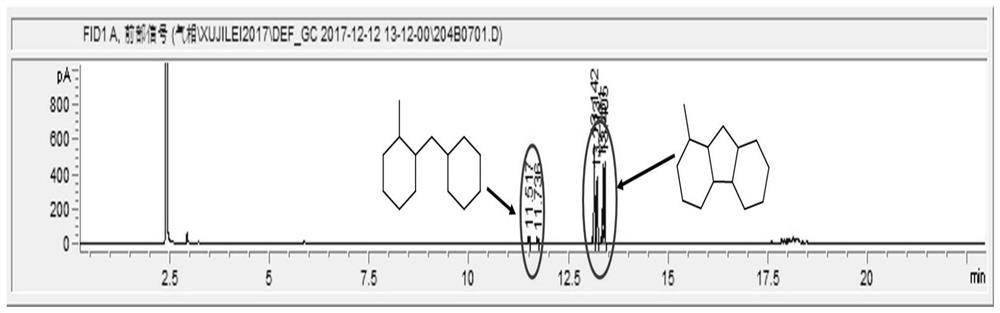

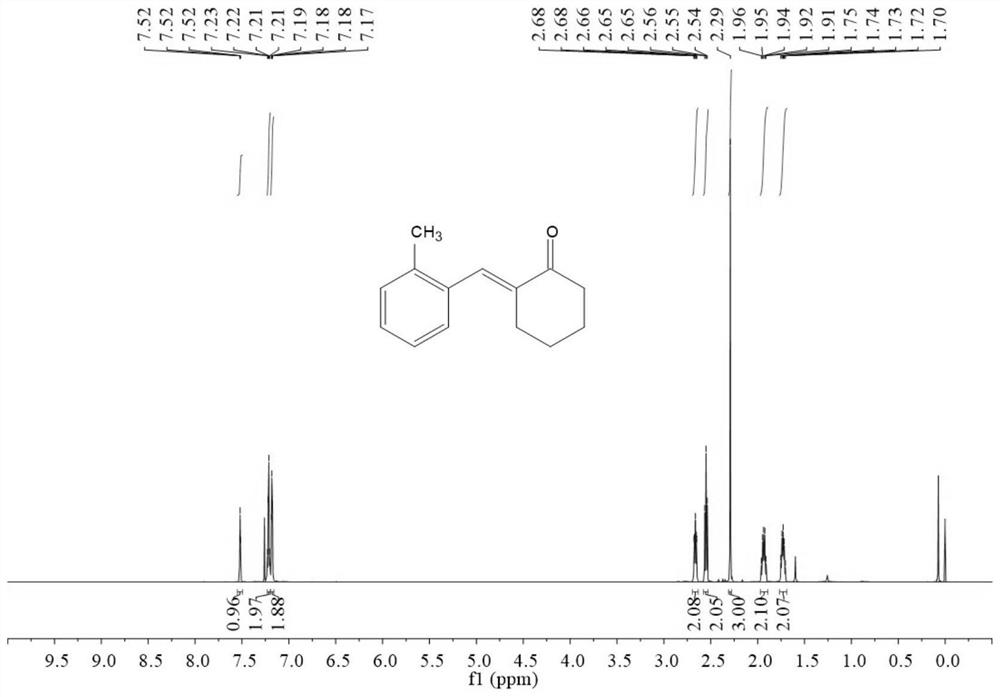

[0051] Analysis can be obtained for the reaction system of Example 11 figure 1 Shown gas chromat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com