Preparation method of multi-sized moissanite

A moissanite, multi-size technology, applied in chemical instruments and methods, polycrystalline material growth, steam from condensation, etc., can solve the problems of low gem production efficiency, difficult gem processing, and high consumption costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

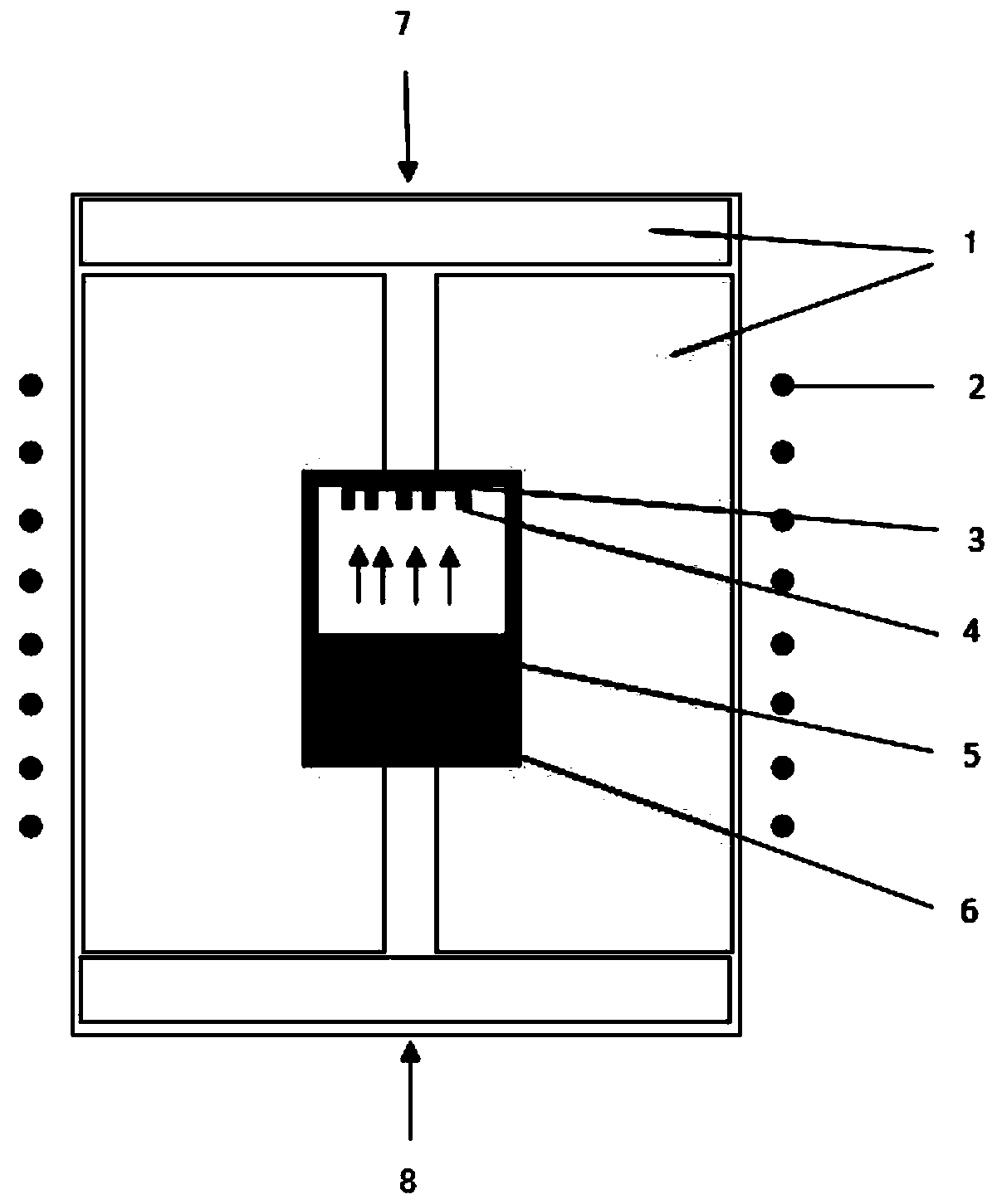

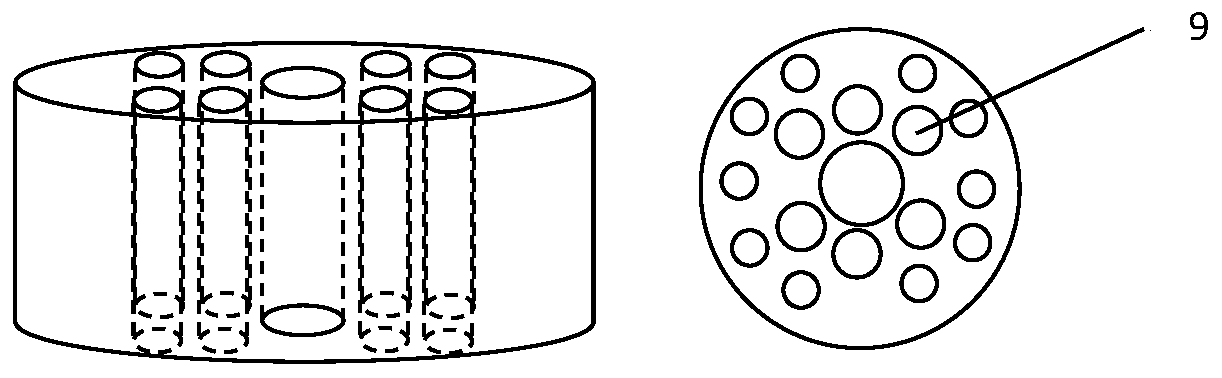

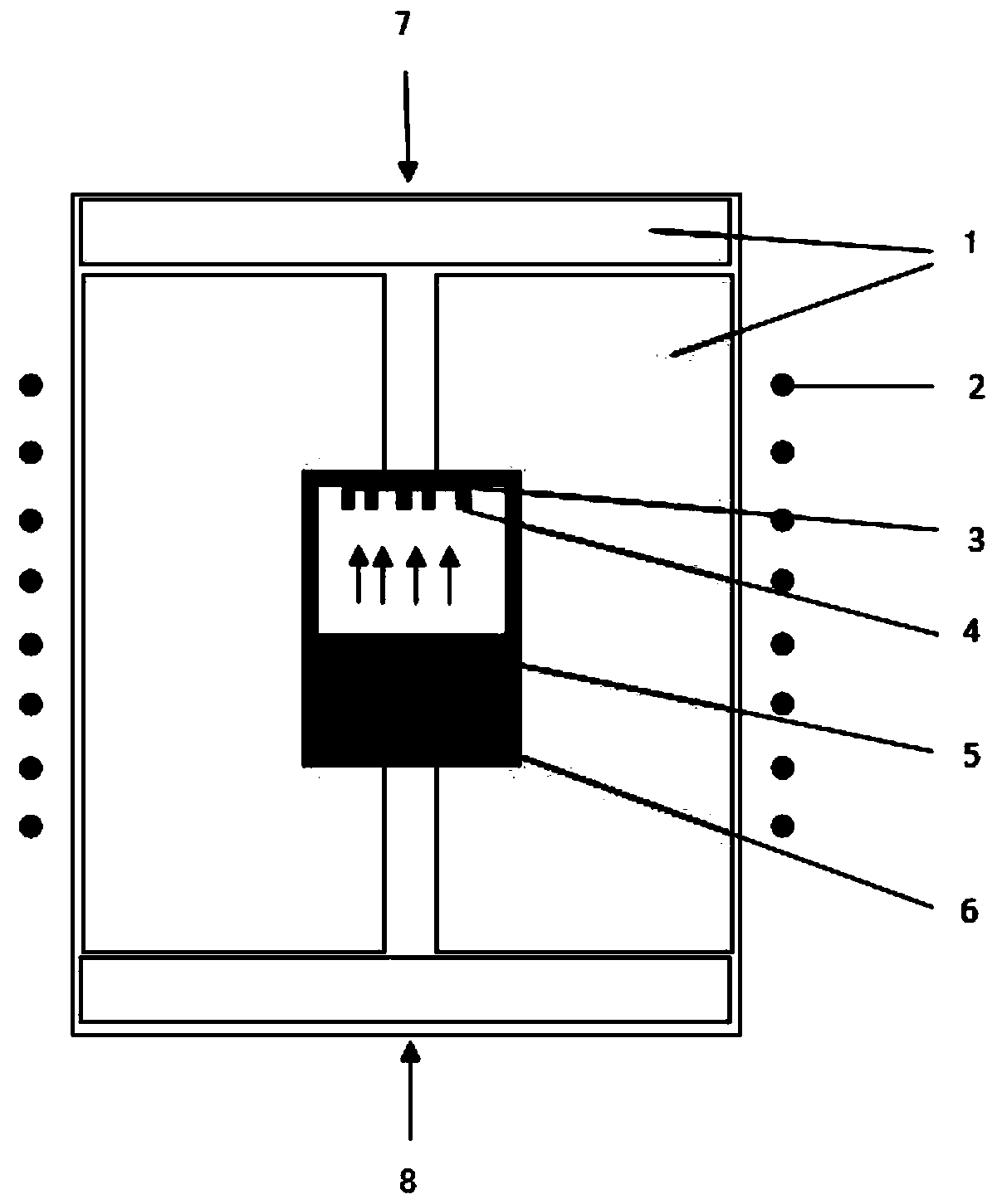

[0028] Aiming at the above-mentioned difficulties existing in the prior art, the present invention provides a method for preparing multi-size moissanite, by using a silicon carbide crystal-porous graphite composite substrate, the back of which is fixed on the inner surface of the graphite crucible lid , the growth surface is placed opposite to the silicon carbide powder raw material; the sealed graphite crucible is placed in a heating furnace for moissanite growth, the growth temperature is in the range of 1900°C-2400°C, the substrate temperature is 1900°C-2300°C, and the raw material The temperature is 2300°C-2400°C, the temperature gradient is 20-50°C / cm, the growth is under an inert gas atmosphere, and the pressure in the reaction chamber is 1×10 -4 Pa-4×10 4 Between Pa, the growth time is more than 70 hours, and moissanite with different sizes can be obtained; the obtained moissanite can be directly used as gem raw material for later gem processing.

[0029] In order to s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com