Gold inlaying method of automobile foot pad

A technology for car foot pads and foot pads, which is applied to chemical instruments and methods, special positions of vehicles, vehicle parts, etc., can solve problems such as falling off of printing patterns, and achieve the effects of improving brightness, improving hydrophobicity and improving vividness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

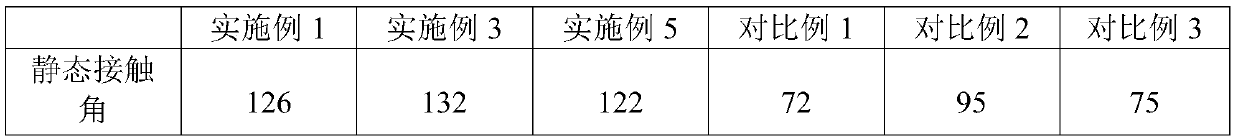

Examples

Embodiment 1

[0022] The modification method of titanium dioxide powder includes the following steps: adding titanium dioxide powder to deionized water for ultrasonic dispersion, the mass ratio of titanium dioxide powder to deionized water is 1:12, to obtain a titanium dioxide suspension, adding ammonia water to adjust the pH to 9, and raising the temperature to 86°C , dropwise add a sodium silicate aqueous solution with a molar concentration of 0.3mol / L to the silica suspension, the mass ratio of the sodium silicate aqueous solution to the titanium dioxide powder is 1:2, age for 2 hours after the addition, and then centrifuge Separation, ultrasonic washing, and drying at a drying temperature of 112°C and a drying time of 16 hours to obtain the final product.

[0023] The method for inlaying gold on car floor mats comprises the following steps:

[0024] 1) Roll the aluminum alloy at 420°C into an aluminum flake with a thickness of 0.30 mm, spray golden pigment powder and titanium dioxide po...

Embodiment 2

[0028] The modification method of titanium dioxide powder includes the following steps: adding titanium dioxide powder to deionized water for ultrasonic dispersion, the mass ratio of titanium dioxide powder to deionized water is 1:14, to obtain a titanium dioxide suspension, adding ammonia water to adjust the pH to 9.5, and raising the temperature to 90°C , dropwise add a sodium silicate aqueous solution with a molar concentration of 0.4mol / L to the silica suspension, the mass ratio of the sodium silicate aqueous solution to titanium dioxide powder is 1:2.5, age for 4 hours after the addition, and then centrifuge Separation, ultrasonic washing, and drying at a drying temperature of 118°C and a drying time of 25 hours to obtain the final product.

[0029] The method for inlaying gold on car floor mats comprises the following steps:

[0030] 1) Roll the aluminum alloy at 500°C into an aluminum flake with a thickness of 0.50 mm, and spray golden pigment powder and titanium dioxid...

Embodiment 3

[0034] The modification method of titanium dioxide powder comprises the following steps: adding titanium dioxide powder to deionized water for ultrasonic dispersion, the mass ratio of titanium dioxide powder to deionized water is 1:10-15, to obtain a titanium dioxide suspension, adding ammonia water to adjust the pH to 9.5, and raising the temperature to At 88°C, dropwise add a sodium silicate aqueous solution with a molar concentration of 0.4mol / L to the silica suspension. The mass ratio of the sodium silicate aqueous solution to titanium dioxide powder is 1:2. After centrifugation, ultrasonic washing, and drying, the drying temperature is 115°C and the drying time is 20h.

[0035] The method for inlaying gold on car floor mats comprises the following steps:

[0036]1) Roll the aluminum alloy at 450°C into an aluminum flake with a thickness of 0.50 mm, and spray golden pigment powder and titanium dioxide powder on the upper surface of the aluminum flake under the above high t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com