High-fullness waterborne polyurethane acrylate paint composition comprising waterborne hydroxyl acrylic dispersoid resin and preparation method of high-fullness waterborne polyurethane acrylate paint composition

A technology of acrylic polyurethane and hydroxyacrylic acid, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of poor water resistance, high content of hydrophilic groups, and poor environmental protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0092] A waterborne hydroxyacrylic acid dispersion resin is prepared by the following method:

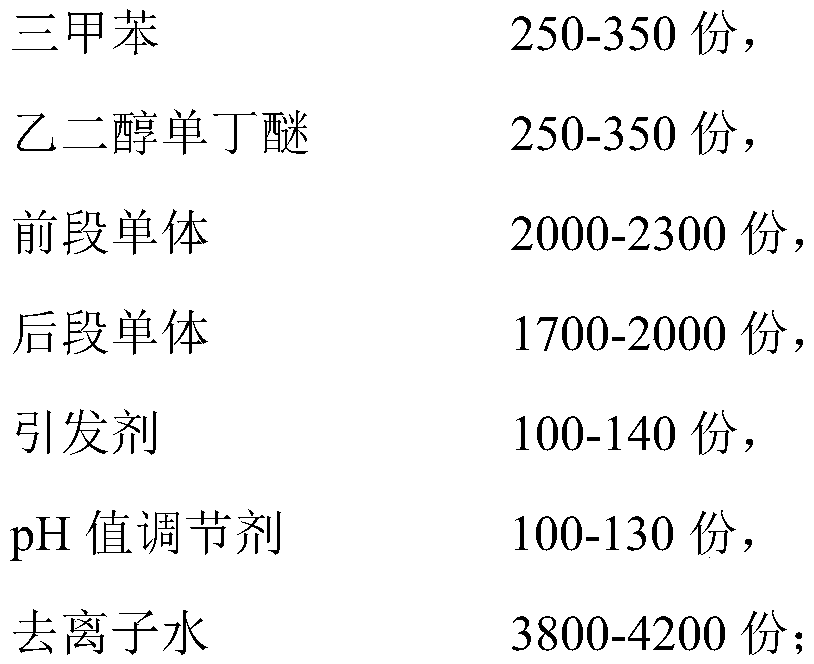

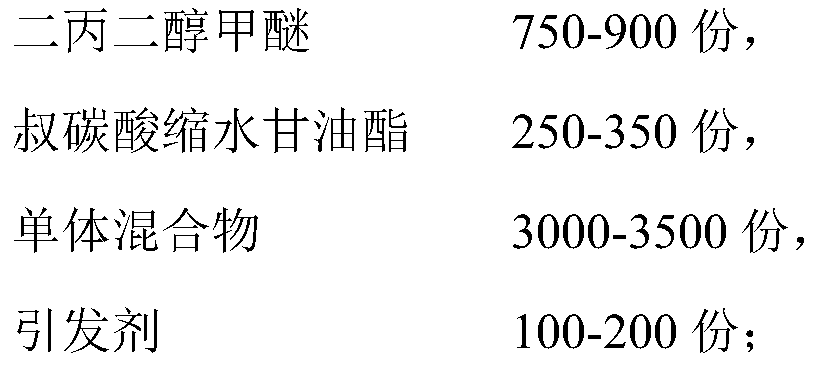

[0093] Add 300 parts of trimethylbenzene and 300 parts of ethylene glycol monobutyl ether into the reaction kettle at one time, stir evenly, raise the temperature to 145°C and keep it warm; under the condition of stirring, add the previous monomers dropwise at a uniform speed, including: 800 parts of methyl methacrylate , 120 parts of methacrylic acid, 620 parts of hydroxyethyl methacrylate, 450 parts of n-butyl acrylate and 200 parts of isooctyl methacrylate, and 50 parts of VAZO 67 initiator were added, and the addition was completed within two hours; 145°C After half an hour of heat preservation reaction, add the latter monomer dropwise, including: 300 parts of methyl methacrylate, 400 parts of styrene, 40 parts of methacrylic acid, 300 parts of hydroxyethyl methacrylate, 600 parts of n-butyl methacrylate and 200 parts of isooctyl methacrylate, and added 50 parts of VAZO 67 initi...

Embodiment 2

[0101] The preparation method of water-based hydroxyacrylic acid dispersion resin and ultra-high solid content hydroxyacrylic resin is the same as that of Example 1.

[0102] A high-fullness waterborne acrylic polyurethane coating composition, prepared by the following method:

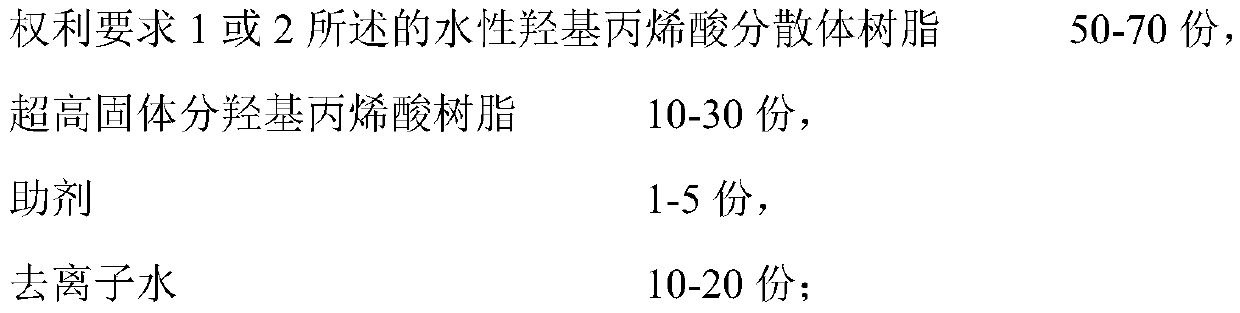

[0103] 1) Mix 25 parts of ultra-high solid hydroxyl acrylic resin, 1 part of water-based wetting agent, 0.5 parts of water-based defoamer, 1 part of water-based aging agent and 2.5 parts of film-forming aid, and use a disperser to stir evenly until it is transparent and clear ; Gradually add 60 parts of water-based hydroxyacrylic acid dispersion resin under stirring condition, add 10 parts of deionized water after stirring evenly, obtain A component, solid content is 50.2wt%, viscosity is 350mPa·S;

[0104] 2) Mix 10 parts of propylene glycol methyl ether acetate, 20 parts of propylene glycol diacetate and 0.5 part of Additive OF, stir for 30 minutes, continue to slowly add 50 parts of Bayhydur XP 2655...

Embodiment 3

[0107] The preparation method of water-based hydroxyacrylic acid dispersion resin and ultra-high solid content hydroxyacrylic resin is the same as that of Example 1.

[0108] A high-fullness waterborne acrylic polyurethane coating composition, prepared by the following method:

[0109] 1) Mix 10 parts of ultra-high solid hydroxyl acrylic resin, 0.5 parts of water-based wetting agent, 0.8 parts of water-based defoamer, 1.5 parts of water-based aging agent and 2 parts of film-forming aid, and use a disperser to stir evenly until it is transparent and clear ; Gradually add 70 parts of water-based hydroxyacrylic acid dispersion resin under stirring condition, add 15 parts of deionized water after stirring evenly, obtain A component, solid content is 46.8wt%, viscosity is 320mPa·S;

[0110] 2) Mix 15 parts of propylene glycol methyl ether acetate, 10 parts of propylene glycol diacetate, 10 parts of dipropylene glycol dimethyl ether and 0.3 parts of Additive OF, stir for 30 minutes,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com