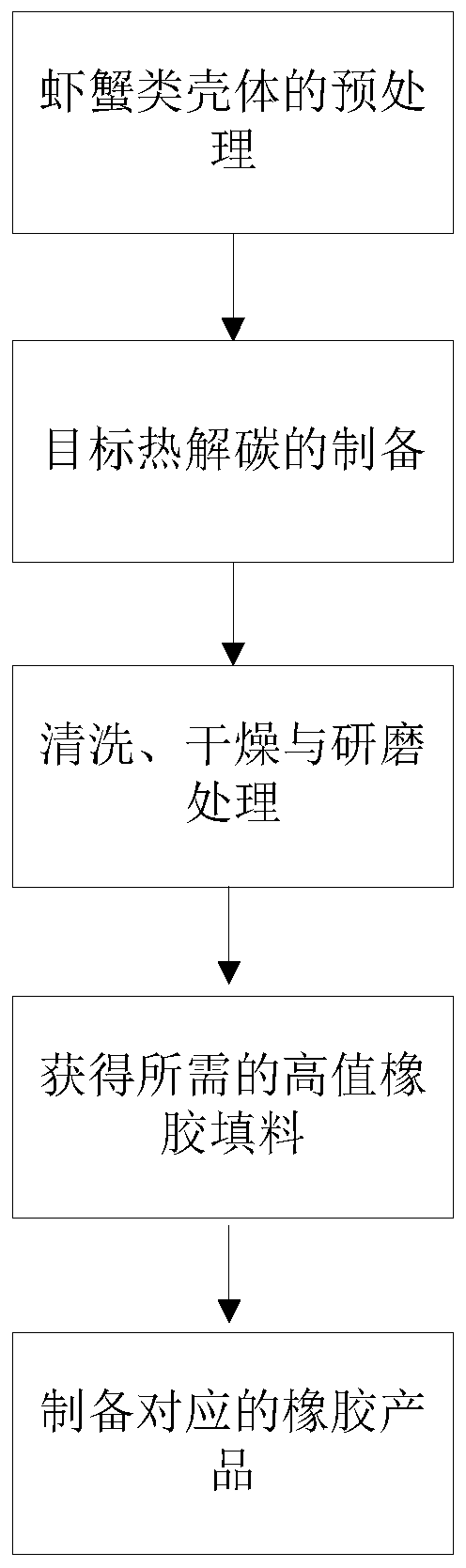

Method for preparing high value rubber fillers based on pyrolysis of shrimp and crab based shells and high value rubber filler product

A technology for rubber fillers and shells, applied in fibrous fillers, dyed low-molecular organic compound treatment, calcium carbonate/strontium/barium, etc., can solve the problem of increasing the cost of calcium carbonate fillers, harsh conditions for calcium carbonate modification, polymer Performance impact and other issues, to achieve the effect of improving the scope of application, increasing the specific surface area, and not easy to agglomerate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] (1) Shell pretreatment: After washing the shrimp shell with clean water, it is crushed to obtain a shell powder sample with a particle size of 0.5-1 cm;

[0042] (2) Preparation of pyrolytic carbon by pyrolyzing the shell powder sample: heat the shell powder sample placed in the reactor by an external heat source, and control the internal temperature of the reactor to 450°C, the temperature of the heat transfer medium bulb to about 570°C, and the thermal The decomposition time is 8 hours; before the start of the pyrolysis, excessive inert gas is passed into the reactor to discharge the air, and the ventilation is stopped after the reaction starts, and the broken shell material is decomposed into semi-coke components and volatile components by heating, and the semi-coke components follow the reaction The lifting plate in the device moves together, and is continuously impacted by the heat transfer medium ball and assists in heat transfer, and at the same time interacts with ...

Embodiment 2

[0049] (1) Shell pretreatment: After washing the shrimp shell with clean water, it is crushed to obtain a shell powder sample with a particle size of 1 to 2 cm;

[0050] (2) Preparation of pyrolytic carbon by pyrolyzing the shell powder sample: heat the shell powder sample placed in the reactor by an external heat source, and control the internal temperature of the reactor to 300 °C, the temperature of the heat transfer medium bulb to about 500 °C, and the thermal The decomposition time is 24 hours; before the start of the pyrolysis, excessive inert gas is passed into the reactor to discharge the air, and the ventilation is stopped after the reaction starts, and the broken material of the shell is decomposed into semi-coke components and volatile components by heating, and the semi-coke components are followed by the reaction The lifting plate in the device moves together, and is continuously impacted by the heat transfer medium ball and assists in heat transfer, and at the sam...

Embodiment 3

[0054] (1) Shell pretreatment: After cleaning the crab shell with clean water, it is crushed to obtain a shell powder sample with a particle size of 1 to 1.5 cm;

[0055] (2) Preparation of pyrolytic carbon by pyrolyzing the shell powder sample: heat the shell powder sample placed in the reactor by an external heat source, and control the internal temperature of the reactor to 600°C, the temperature of the heat transfer medium bulb to about 660°C, and the thermal The decomposition time is 5.5 hours; before the start of pyrolysis, excessive inert gas is passed into the reactor to discharge the air, and the ventilation is stopped after the reaction starts, and the broken material of the shell is decomposed into semi-coke components and volatile components by heating, and the semi-coke components follow the The lifting plate in the reactor moves together, and is constantly impacted by the heat transfer medium ball to assist in heat transfer, and at the same time interacts with the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com