High water vapor barrier type epoxy resin composition and application of same in lithium-ion power batteries

An epoxy resin and water vapor barrier technology, applied in epoxy resin glue, secondary battery, battery pack parts and other directions, can solve the problems of expensive curing agent, insufficient water vapor barrier property, and no mention of water vapor barrier property, etc. To achieve the effect of increasing the path and improving the water vapor barrier

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

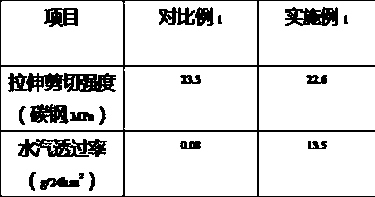

Examples

Embodiment 1

[0026] 50g bisphenol A type epoxy resin, 16g epoxy-terminated nitrile rubber, 0.4g trifluorooctyl methacrylate, 3g organic montmorillonite, 0.1g 1000 mesh polyacrylamide powder, 30g fatty amine curing agent and 0.5 g of 2,4,6-tris(dimethylaminomethyl)phenol were uniformly mixed at a temperature of 25° C. to obtain a high water vapor barrier epoxy resin composition.

Embodiment 2

[0028] 10g bisphenol A type epoxy resin, 10g bisphenol F type epoxy resin, 5g polysulfide rubber, 58.5g silicon micropowder, 10g 2-ethylhexyl glycidyl ether, 0.1g heptadecanofluorodecyltriethoxy Silane, 5g of boron nitride nanosheets, 0.05g of 20000 mesh polyacrylamide powder, 3g of polyamide curing agent and 0.35g of K-54 are mixed uniformly at a temperature of 25°C to obtain a high water vapor barrier epoxy resin composition .

Embodiment 3

[0030] 40g novolac epoxy resin, 20g bisphenol S type epoxy resin, 8.9g glycidyl ester epoxy resin, 5g core-shell polymer, 5g nitrile rubber, 2.5g heptadecanofluorodecyltriethoxysilane, Mix 2.5g trifluorooctyl methacrylate, 0.1g layered double hydroxide, 1g 20000 mesh polyacrylamide powder, 10g alicyclic amine curing agent and 5g polythiol curing agent at a temperature of 100°C , to obtain a high water vapor barrier epoxy resin composition.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com