Method for preparing carbon nanofiber by taking halloysite as catalyst

A technology of carbon nanofibers and catalysts, applied in the fields of fiber chemical characteristics, textiles and papermaking, etc., can solve the problems of high price, complex synthesis process, high synthesis temperature, etc., and achieve the effect of low price, rich sources and wide sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

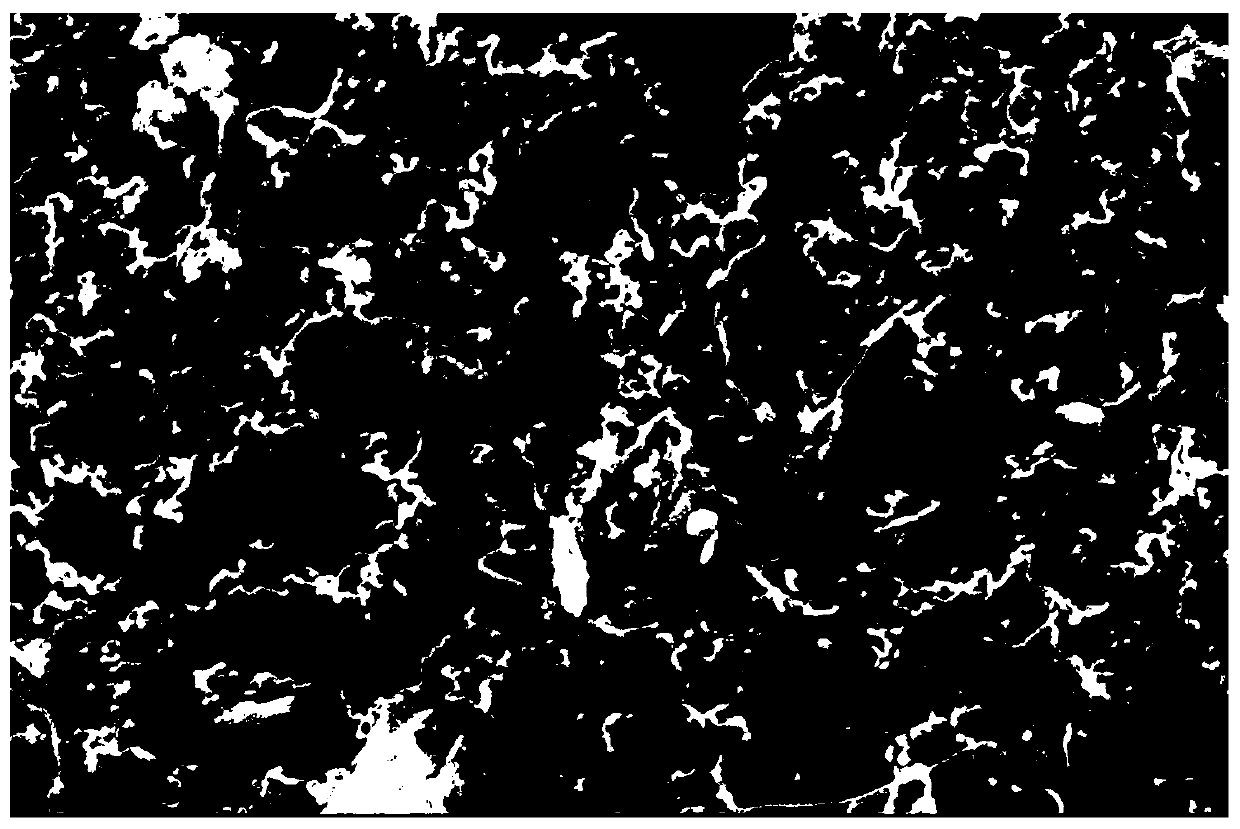

Image

Examples

Embodiment 1

[0028] 100g of halloysite powder was placed in a muffle furnace, calcined at 700°C for 60min, and cooled naturally to obtain a thermally activated halloysite catalyst.

[0029] Dissolve 5g of polybutylene terephthalate / adipate (PBAT) in 50ml of dichloromethane; add 0.5% of the above-mentioned halloysite catalyst, stir ultrasonically for 30min, cast it in a mold, and obtain a PBAT compound after volatilizing the solvent thing.

[0030] Put the PBAT composite in a ceramic crucible, place it in a tube furnace, raise the temperature to 550° C. under a nitrogen atmosphere, heat for 45 minutes, and cool to room temperature to obtain carbon nanofibers.

Embodiment 2

[0032] Place 100g of halloysite powder in a muffle furnace and calcinate at 800°C for 45min. After natural cooling, disperse the sample in ethanol to form a 0.5g / ml suspension. The mixture was reacted for 12 hours, centrifuged, dried at 120° C., crushed and ground to obtain a modified halloysite catalyst.

[0033] According to the mass ratio, 2% of the above-mentioned halloysite catalyst and 98% of polyethylene terephthalate (PET) are evenly mixed and then added to an extruder for melt mixing to obtain a PET compound. Extrusion temperature: 115, 160, 200, 220, 150°C, rotation speed: 150 rpm.

[0034] Put the PET compound in a ceramic crucible, place it in a high-temperature furnace, raise the temperature to 700°C under a nitrogen atmosphere, heat it for 45 minutes, and cool it down to room temperature to obtain carbon nanofibers.

Embodiment 3

[0036] Place 100g of halloysite powder in a muffle furnace and calcinate at 650°C for 45min. After natural cooling, disperse the sample in ethanol to form a 1g / ml suspension. React for 10 hours, centrifuge, dry at 120° C., crush and grind to obtain a modified halloysite catalyst.

[0037] According to the mass ratio, 5% of the above halloysite catalyst and 95% of PBAT are uniformly mixed and then added to an extruder for melt mixing to obtain a PBAT compound. Extrusion temperature: 100, 110, 150, 170, 120°C, rotation speed: 200 rpm.

[0038] Put the PBAT composite in a ceramic crucible, place it in a high-temperature furnace, and raise the temperature to 550° C. under a nitrogen atmosphere, heat for 90 minutes, and cool to room temperature to obtain carbon nanofibers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com