Heat sensitive paper applicable to tags without bottom paper and manufacturing method of heat sensitive paper

A manufacturing method and heat-sensitive paper technology, which is applied in special paper, paper, papermaking, etc., can solve the problems that the coated base material affects the roughness of the finished product, the surface fineness of the coated base paper is poor, and the coating uniformity is affected. High surface smoothness, low roughness, smooth marking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

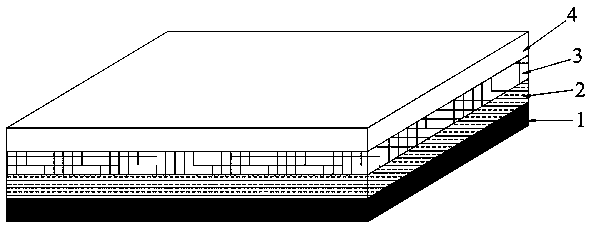

[0029] A thermal paper suitable for linerless labels such as figure 1 As shown, it consists of substrate layer 1, primer layer 2, heat-sensitive layer 3, and protective layer 4 from bottom to top. The substrate layer 1 is preferably wood pulp base paper, the smoothness of the coated surface is ≥ 90s, and the smoothness of the non-coated surface is ≥ 50s. The two components of the primer layer contain calcined kaolin, hollow spherical plastic pigments and styrene-butadiene latex, and the solid content of the hollow spherical plastic pigments accounts for more than 40% of the total solid content of the components. The heat-sensitive layer 3 contains styrene-butadiene latex or polyvinyl alcohol as an adhesive, and contains a polyolefin polymer resin water-repellent agent. The 4 components of the protective layer contain modified polyvinyl alcohol, a crosslinking agent, and a water-repellent agent for polyolefin polymer resin.

Embodiment 2

[0030] Embodiment 2: prepare primer coating solution

[0031] First, weigh the components for preparing the primer coating in the following parts by weight: 0.5 to 1.0 parts of inorganic dispersant, 20 to 40 parts of calcined kaolin, 40 to 70 parts of hollow spherical plastic pigments, 5 to 15 parts of styrene-butadiene latex, Calcium stearate lubricant 2-4 parts, defoamer 1-2 parts. Then, add water to the preparation tank, start stirring, add inorganic dispersant, slowly add calcined kaolin, 600rpm / min high-speed dispersion for 60min, then add hollow spherical plastic pigment, styrene-butadiene latex, lubricant and defoamer, 100rpm / min low speed After stirring for 20 minutes, measure the solids content of the coating to form a primer coating solution for later use.

Embodiment 3

[0032] Embodiment 3: Preparation of thermosensitive layer coating solution

[0033]First, weigh the components for preparing the heat-sensitive layer coating according to the following parts by weight: 0.5 to 1 part of dispersant, 30 to 40 parts of light calcium carbonate grinding liquid, 20 to 30 parts of developer grinding liquid, 10 parts of leuco dye ~20 parts, 5~15 parts of sensitizer grinding liquid, 3~6 parts of PVA glue, 1~2 parts of wetting agent, 2~3 parts of lubricant, 3~8 parts of polyolefin polymer resin water repellent , 0.5 to 1 part of defoamer. Then, add a small amount of water to the heat-sensitive layer preparation tank, start stirring, and then add dispersant, light calcium carbonate grinding liquid, color developer grinding liquid, leuco dye grinding liquid, sensitizer grinding liquid, 300rpm / min speed Stir for 40 minutes, then add PVA glue, wetting agent, lubricant, polyolefin polymer resin anti-water agent and defoamer in sequence, continue stirring for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com