Method for manufacturing imitated ceramic leak-proof glass bottle body and imitated ceramic leak-proof glass bottle

A technology of glass bottles and imitation ceramics, which is applied in the field of preparing imitation ceramic leak-proof glass bottles and imitation ceramic leak-proof glass bottles. Internal, good anti-leakage performance, high compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

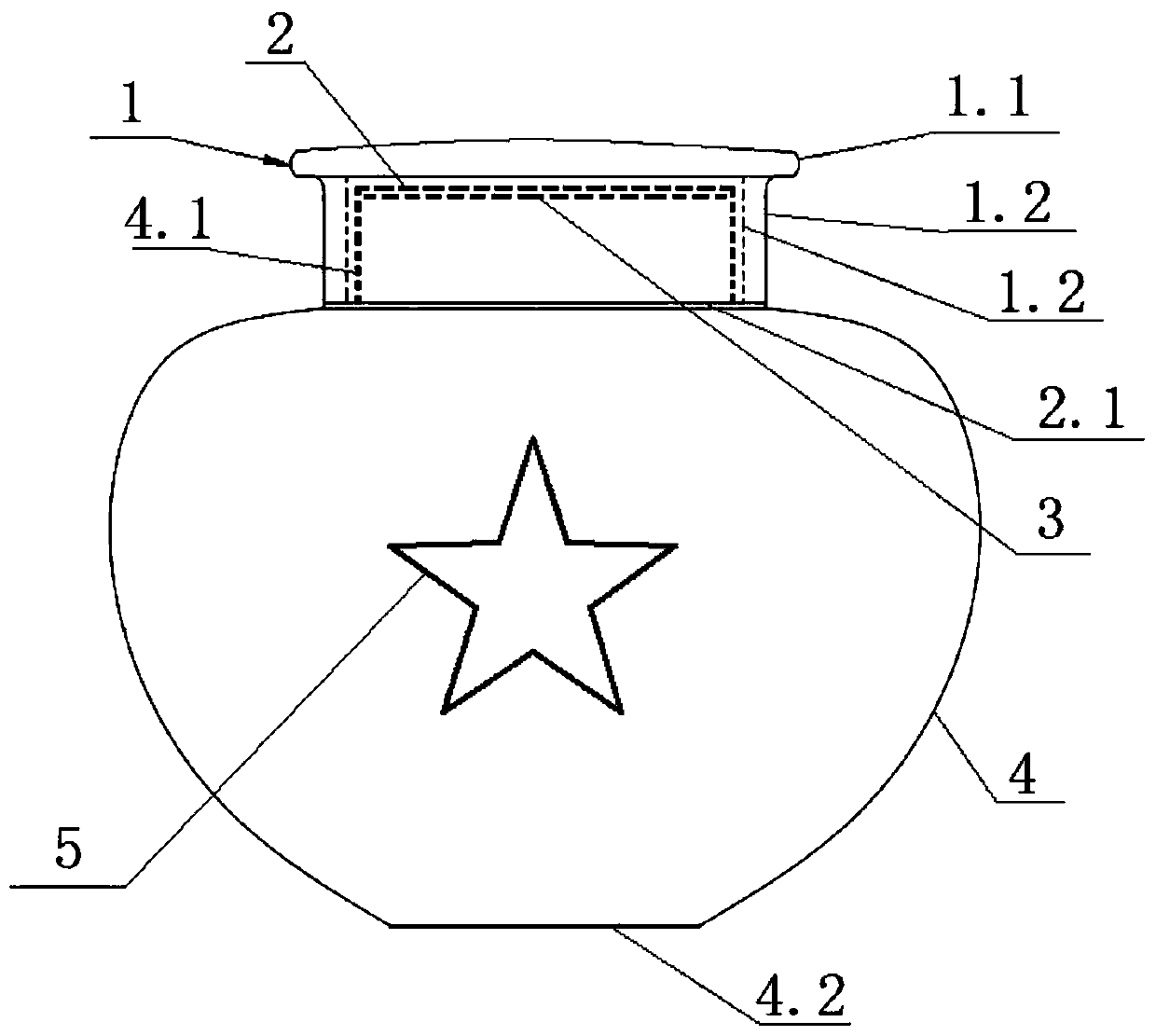

[0044] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but they do not constitute a limitation to the present invention, and are only examples. At the same time, the advantages of the present invention are clearer and easier to understand through the description.

[0045] The method for preparing imitation pottery leak-proof glass bottle body comprises the following steps,

[0046] Step 1: raw material preprocessing,

[0047] Select the raw materials of the imitation ceramic leak-proof glass bottle and determine its dosage. The selected raw materials of the imitation ceramic leak-proof glass bottle include cullet, soda ash, quartz sand, feldspar powder, sodium nitrate, fluorite, sodium fluorosilicate, calcite and titanium dioxide Respectively take a certain weight portion of the imitation ceramic leak-proof glass bottle raw material, crush and dry the imitation ceramic leak-proof glass bottle raw mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com