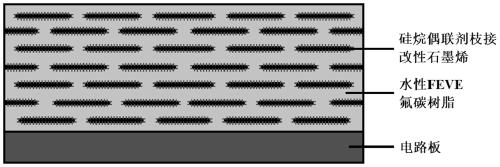

Modified graphene enhanced waterborne FEVE fluorine-carbon flexible protection paint and coating

A flexible protection and graphene technology, applied in anti-corrosion coatings, coatings, etc., can solve the problems of affecting heat dissipation performance, poor heat dissipation performance, poor weather resistance and impact resistance of coatings, etc., and achieve good flexibility and ductility , Anti-salt spray corrosion performance is remarkable, the effect of protection performance is remarkable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Firstly, the graphene is grafted and modified with a silane coupling agent to prepare a grafted modified graphene functional filler. The steps are as follows: take 1 part of graphene, 5 parts of silane coupling agent γ-aminopropyl Ethylsilane, 80 parts of ethanol and 10 parts of deionized water were prepared as a mixture, mechanically stirred for 1 h, and left to stand for 0.5 h; then the mixture was heated to 65 °C in a water bath, kept warm and mechanically stirred for 2 h, and ultrasonically dispersed for 0.5 h to make the graphite ene and the silane coupling agent fully react to complete the graft modification of graphene; then the reacted mixture is alternately washed with acetone and deionized water, and dried to prepare a graft-modified graphene functional filler.

[0039]Then, utilize the prepared graft modified graphene functional filler to prepare modified graphene to strengthen the waterborne FEVE fluorocarbon coating, its steps are as follows: get 0.3 part of...

Embodiment 2

[0043] Preparation of grafted modified graphene functional filler: Take 1 part of graphene, 15 parts of γ-aminopropyltriethylsilane, 60 parts of ethanol and 8 parts of deionized water to make a mixture, mechanically stir for 1h, and let stand for 0.5h ; use a water bath to heat the mixture to 70 ° C, keep warm and continue to mechanically stir for 2 hours, and ultrasonically disperse for 0.5 hours; alternately use acetone and deionized water to wash and dry to make a grafted modified graphene functional filler.

[0044] Preparation of flexible protective coating: take 1 part of grafted modified graphene functional filler and 30 parts of diluent (wherein the mass fractions of propylene glycol and water are 70% and 30% respectively), mix and mechanically stir for 2h, and ultrasonically disperse for 2h; Add the dispersed above mixture to 55 parts of water-based FEVE fluorocarbon resin, mechanically stir for 2 hours, and ultrasonically disperse for 2 hours; add 0.5 parts of polydim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com