A kind of microetching agent for magnesium alloy and surface treatment process before nano-injection molding

A nano-injection molding and magnesium alloy technology, applied in the field of magnesium alloy surface treatment, can solve the problems of high cost, difficult and difficult treatment, and achieve the effect of enhancing bonding force and no health threat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

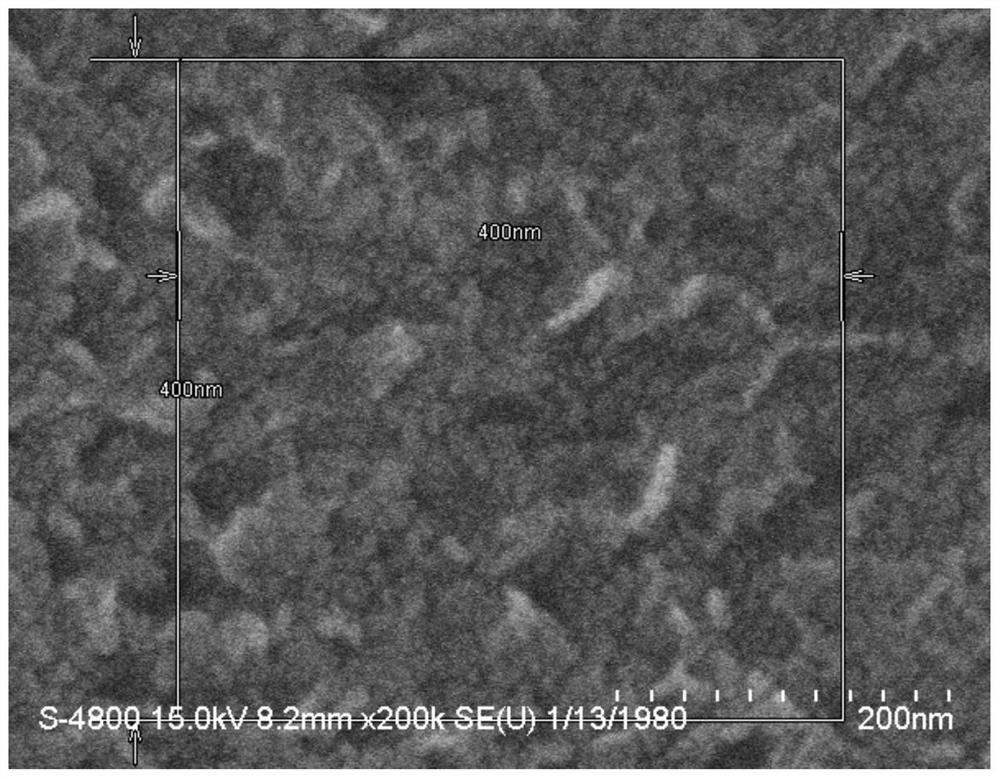

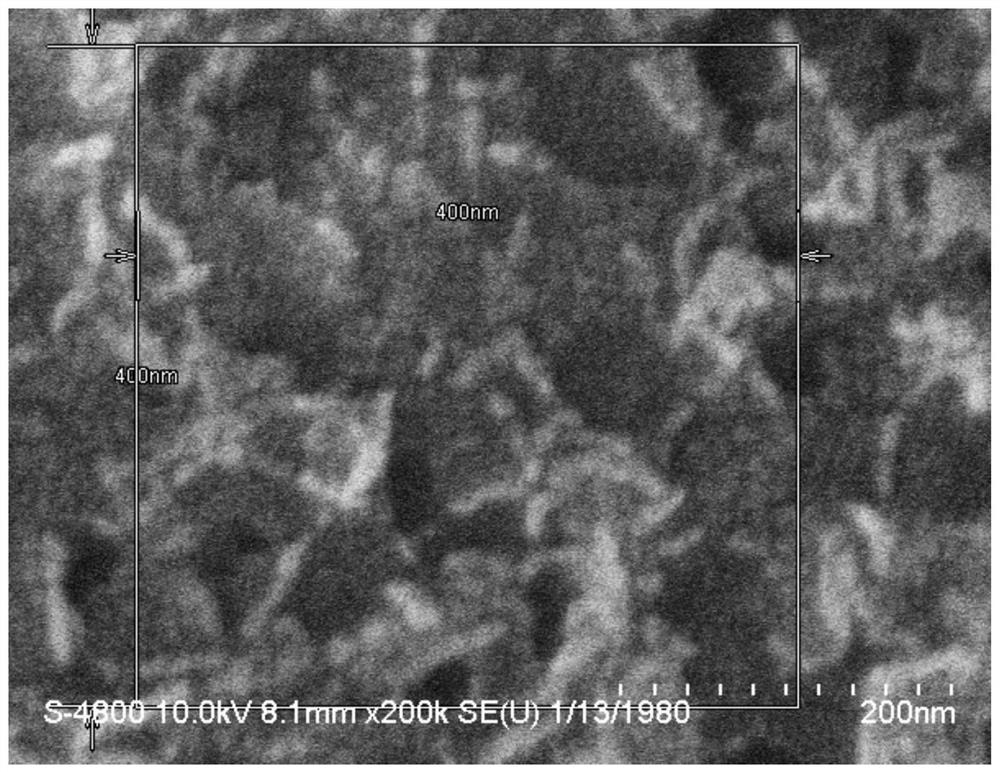

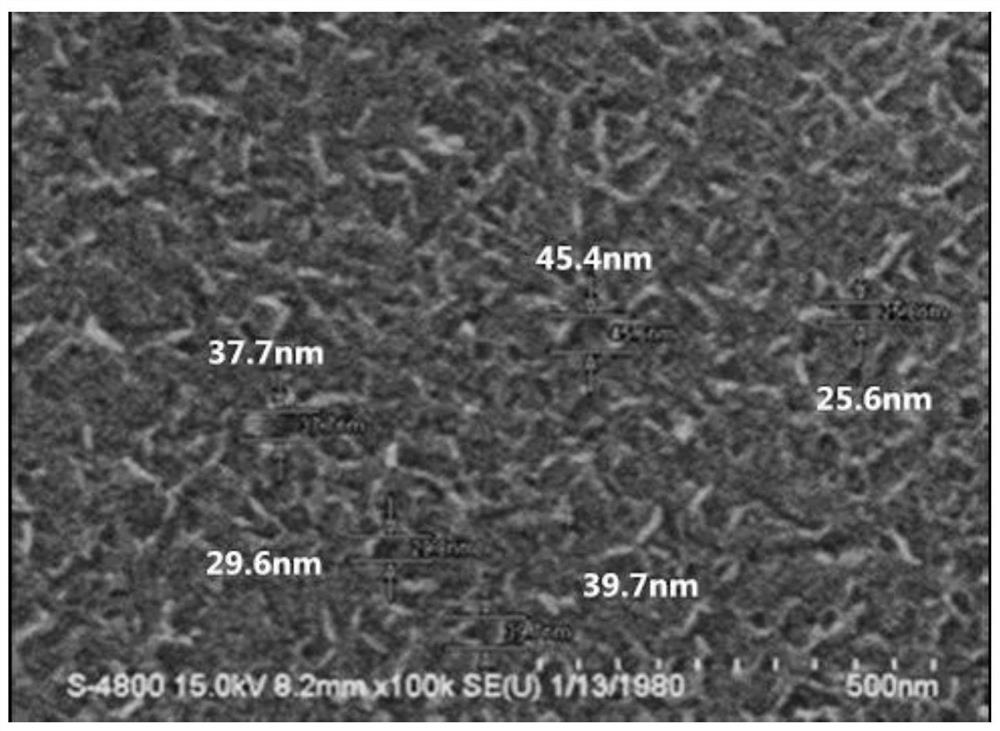

Image

Examples

Embodiment 1

[0043] This embodiment discloses a magnesium alloy microetch, which includes the following components in parts by weight:

[0044] Sulfuric acid: 50 parts;

[0045] Tartaric acid: 100 parts;

[0046] Sodium nitrate: 20 parts;

[0047] Ethylene glycol: 50 parts;

[0048] Sodium lauryl sulfate: 1 part;

[0049] Pure water: 789 parts.

[0050] Preparation method: Stir and mix the above-mentioned ingredients uniformly to prepare Example 1 of magnesium alloy microetch agent.

Embodiment 2

[0052] This embodiment discloses a magnesium alloy microetch, which includes the following components in parts by weight:

[0053] Nitric acid: 100 parts;

[0054] Malic acid: 50 parts;

[0055] Potassium nitrate: 30 parts;

[0056] Polyethylene glycol: 50 parts;

[0057] Sodium dodecylbenzenesulfonate: 5 parts;

[0058] Pure water: 765 parts.

[0059] Preparation method: Stir and mix the above-mentioned ingredients uniformly to prepare Example 2 of magnesium alloy microetch agent.

Embodiment 3

[0061] This embodiment discloses a magnesium alloy microetch, which includes the following components in parts by weight:

[0062] Sulfuric acid: 100 parts;

[0063] Lactic acid: 100 parts;

[0064] Sodium nitrite: 30 parts;

[0065] Glycerol: 50 parts;

[0066] Sodium lauryl sulfate: 5 parts;

[0067] Pure water: 715 parts.

[0068] Preparation method: Stir and mix the above-mentioned ingredients uniformly to prepare Example 3 of magnesium alloy microetch agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com