Method for preparing cellulose nanofibrils with surfaces containing carboxyls and quaternary ammonium groups

A technology of nanofibrils and cellulose is applied in the field of preparation of natural polymer materials to achieve superior gel-like properties, reduced energy consumption and significant thickening effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

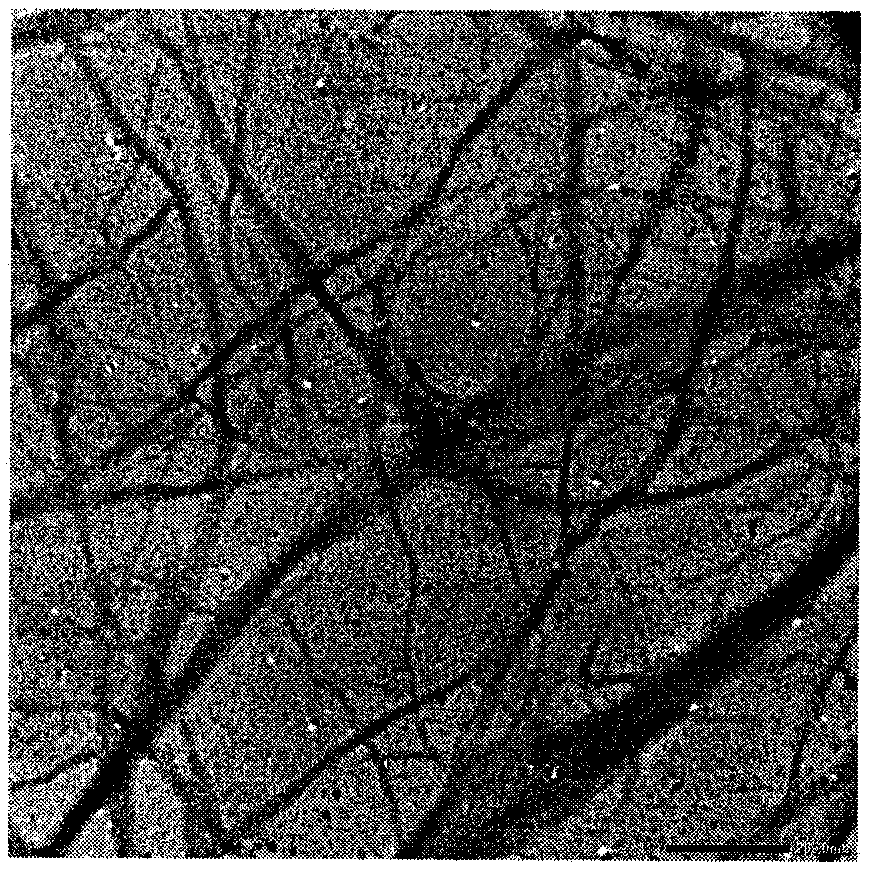

Image

Examples

Embodiment 1

[0027] Stir 49g of anhydrous oxalic acid and 40g of anhydrous betaine at 90°C for 5min to form a eutectic system, then add 2g of bleached hardwood pulp to the system, continue to react at 90°C for 5h, and add 100g of distilled water at 70°C, and let stand at room temperature for 5 minutes to swell the fibers. Add 200g of 80°C distilled water for dilution, then centrifuge at 6000r / min for 5min, pour out the supernatant and keep the precipitate, disperse the obtained precipitate with 400g of distilled water, and then centrifuge at 6000r / min for 5min. Repeat this centrifugation washing process with distilled water 4 times. Add 100g of distilled water to the precipitate obtained after washing to obtain a pretreated concentration of 2% cellulose solution, which is subjected to high-pressure homogenization mechanical treatment, and the homogeneous pressure used in the high-pressure homogenization process is 700bar. The number of homogenization cycles is 4 times to obtain a cellulos...

Embodiment 2

[0030] Stir 74g of anhydrous oxalic acid and 40g of anhydrous betaine at 110°C for 10 minutes to form a eutectic system, then add 5g of bleached softwood pulp to the system, continue to react at 110°C for 2 hours, and add 200g of distilled water at 70°C, and stand at room temperature for 10 minutes to swell the fibers. Add 700g of 95°C distilled water for dilution, then centrifuge at 6000r / min for 5min, pour out the supernatant and keep the precipitate, disperse the obtained precipitate with 300g of distilled water, and then centrifuge at 6000r / min for 5min. Repeat this centrifugation washing process with distilled water 4 times. Add 250 g of distilled water to the precipitate obtained after washing to obtain a pretreated cellulose solution with a concentration of 2%, which is subjected to high-pressure homogenization mechanical treatment, and homogenized 3 times at a homogenization pressure of 1300 bar.

[0031] The yield of the obtained cellulose nanofibrils is 80%; its par...

Embodiment 3

[0033]Stir 19g of anhydrous oxalic acid and 40g of betaine hydrochloride at 90°C for 5min to form a eutectic system, then add 1g of bleached grass pulp to the system, continue to react at 90°C for 5h, and add 50g of 70 ℃ distilled water, and stand at room temperature for 5 minutes to make the fibers swell. Add 200g of 70°C distilled water for dilution, then centrifuge at 10000r / min for 5min, pour out the supernatant and keep the precipitate, disperse the obtained precipitate with 100g of distilled water, and then centrifuge at 10000r / min for 5min. Repeat this centrifugation washing process with distilled water 6 times. Add 100g of distilled water to the precipitate obtained after washing to obtain a pretreated concentration of 1% cellulose solution, which is subjected to high-pressure homogenization mechanical treatment. The homogeneous pressure used in the high-pressure homogenization process is 1300bar. The number of homogenization cycles is 4 times to obtain a cellulose na...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com