Method for repairing mine soil contaminated by heavy metals

A soil remediation and heavy metal technology, applied in the field of soil remediation, can solve problems such as adverse effects on human health in the growing environment, reduce microbial activity and stability, disrupt plant metabolism, etc. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

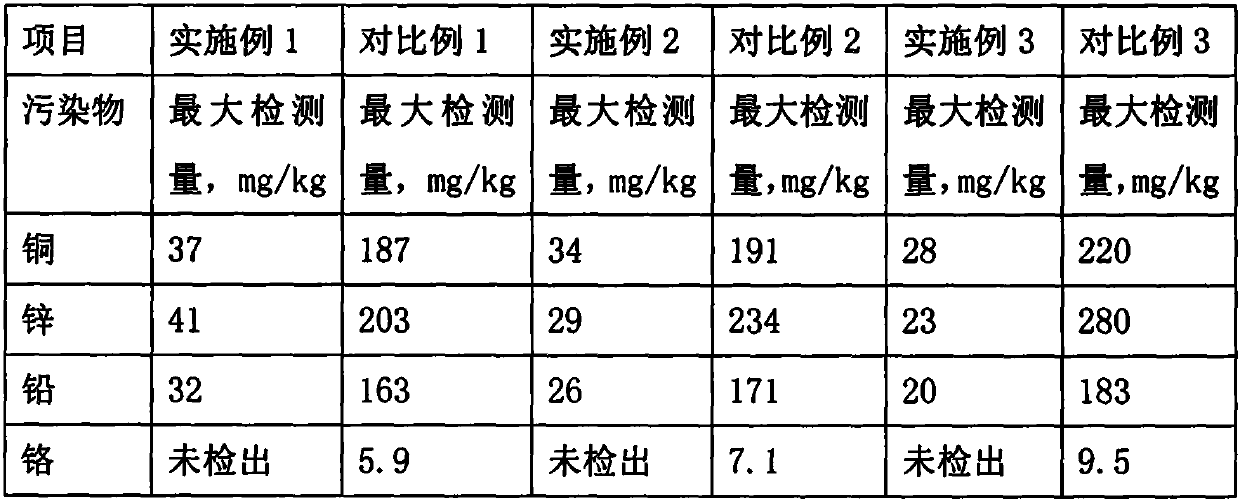

Embodiment 1

[0024] A mine soil remediation method polluted by heavy metals comprises the following steps:

[0025] (1) Add montmorillonite to a buffer solution with a pH value of 8, and after ultrasonic dispersion is uniform, add sodium silicate to it, react for 3 hours, filter to obtain a precipitate, and dry the precipitate to obtain a modified montmorillonite Soil, wherein, the buffer solution is made of 0.1mol / L disodium hydrogen phosphate and 0.1mol / L sodium dihydrogen phosphate according to the volume ratio of 1:1, and the pH value is adjusted to 8 by using sodium hydroxide solution. , the adding mass ratio of montmorillonite and sodium silicate is 10:1;

[0026] (2) In parts by weight, add 24 parts of ferric chloride hexahydrate to 250 parts of deionized water, after the ultrasonic dispersion is uniform, nitrogen gas is introduced under mechanical stirring for 15 minutes to remove the oxygen in the solution after ultrasonic dispersion, and continue to add 35 parts of ammonia water...

Embodiment 2

[0029] A mine soil remediation method polluted by heavy metals comprises the following steps:

[0030] (1) Add montmorillonite to a buffer solution with a pH value of 8, and after ultrasonic dispersion is uniform, add sodium silicate to it, react for 3.5 hours, filter to obtain a precipitate, and dry the precipitate to obtain a modified montmorillonite Soil, wherein, the buffer solution is made of 0.1mol / L disodium hydrogen phosphate and 0.1mol / L sodium dihydrogen phosphate according to the volume ratio of 1:1, and the pH value is adjusted to 8 by using sodium hydroxide solution. , the adding mass ratio of montmorillonite and sodium silicate is 10:2;

[0031] (2) In parts by weight, add 26 parts of ferric chloride hexahydrate to 280 parts of deionized water, after the ultrasonic dispersion is uniform, nitrogen gas is introduced under mechanical stirring for 15 minutes to remove the oxygen in the solution after ultrasonic dispersion, and continue to add 38 parts of ammonia wat...

Embodiment 3

[0034] A mine soil remediation method polluted by heavy metals comprises the following steps:

[0035](1) Add montmorillonite to a buffer solution with a pH value of 9, and after ultrasonic dispersion is uniform, add sodium silicate to it, react for 4 hours, filter to obtain a precipitate, and dry the precipitate to obtain a modified montmorillonite Soil, wherein, the buffer solution is made of 0.1mol / L disodium hydrogen phosphate and 0.1mol / L sodium dihydrogen phosphate according to the volume ratio of 1:1, and its pH value is adjusted to 9 by using sodium hydroxide solution. , the adding mass ratio of montmorillonite and sodium silicate is 10:3;

[0036] (2) In parts by weight, 28 parts of ferric chloride hexahydrate were added to 300 parts of deionized water, and after the ultrasonic dispersion was uniform, nitrogen gas was introduced under mechanical stirring for 15 minutes to remove the oxygen in the solution after ultrasonic dispersion, and then continue to add 40 parts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com