Microorganism electrolytic tank and organic matter oxidation and degradation synchronous CO2 methanation method

A technology of microbial electrolytic cell and bioelectrode, applied in the field of microbial electrolytic cell and its enhanced oxidative degradation of organic matter and synchronous CO2 methanation, which can solve imperfections and other problems, and achieve the effects of strengthening attachment growth, increasing transmission flux, and reducing crossover

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

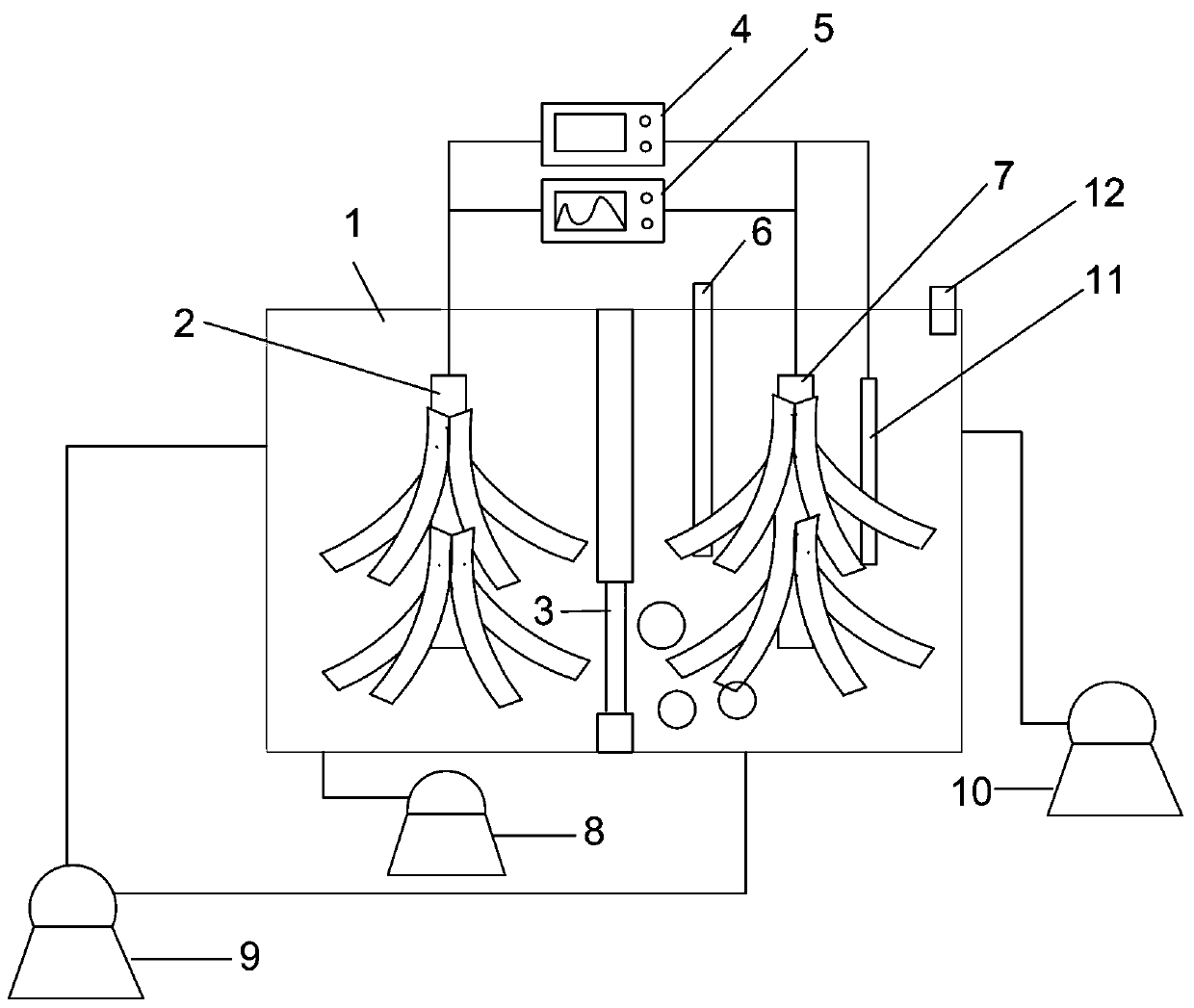

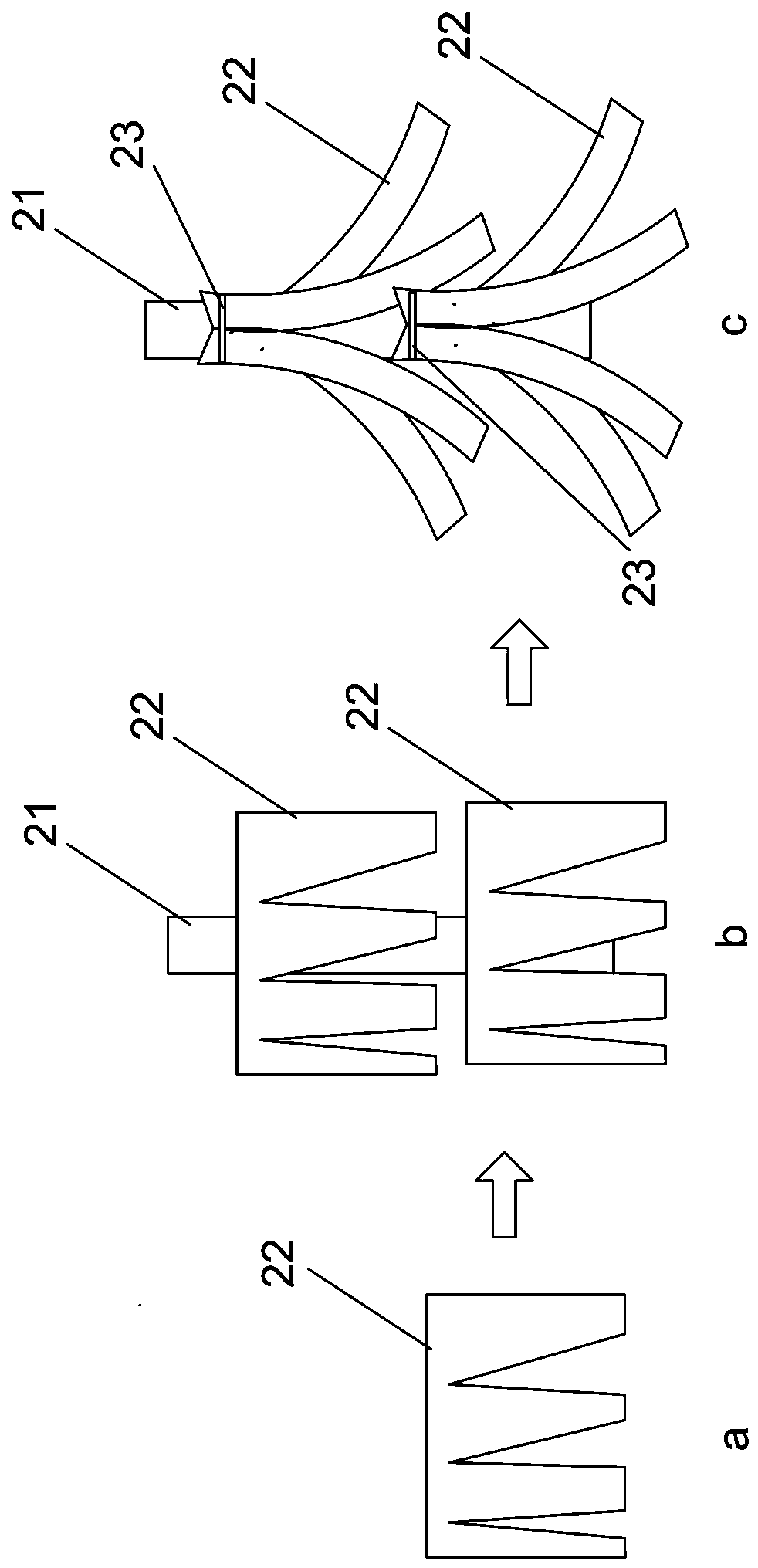

[0035] See attached figure 1 , the preparation and use of the electrolyte solution and trace solution added in the anode and cathode are the same as in Comparative Example 1, and the culture device adopts a 520 mL double-chamber MEC reactor 1, wherein the anode chamber and the cathode chamber are each 260 mL, including a 200 mL reaction volume With 60 mL of headspace for biogas collection. The average distance between the anode and the cathode is 4.0 cm. The two poles are connected to the potentiostat 4 through an external circuit to provide the required potential of -0.6 V. The two electrode materials used are carbon rod electrodes 21 wound by graphite felt 22 . The substrate of the anode chamber is the sludge supernatant diluted with the electrolyte, and its COD concentration is 3070.2 mg / L, which is used as the substrate of the anode chamber. Electrolyte and 5 mL of inoculated sludge were directly added to the cathode chamber, and the pH of the electrolyte in the cathode ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com