Method for preventing and controlling non-point source pollution by comprehensive utilization of farming waste

A technology for breeding waste and non-point source pollution, applied in the field of non-point source pollution control, can solve problems such as unsatisfactory biogas, inability to solve manure water and other problems, and achieve the effect of block processing speed and short fermentation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

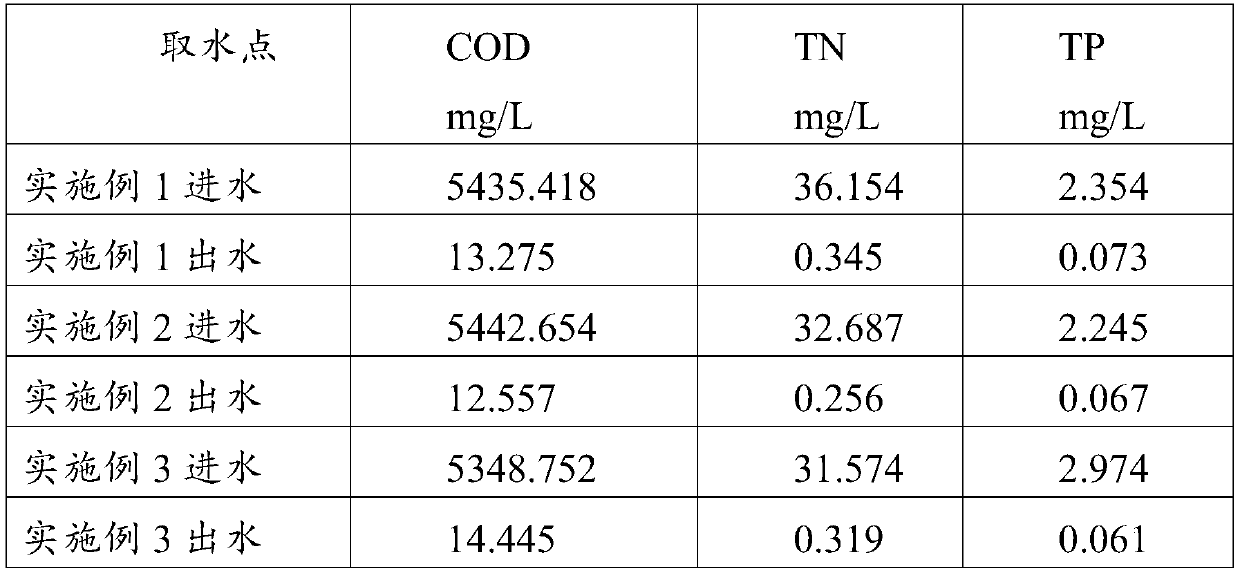

Embodiment 1

[0022] The invention provides a method for the comprehensive utilization of breeding waste to prevent and control non-point source pollution, which comprises the following steps:

[0023] Step 1, passing the feces into the fermenter, adding water to adjust so that the solid content is 30%, and sterilizing at a temperature of 120° C. for 45 minutes;

[0024] Step 2, adding 10% rice straw powder and 4% bacterial agent to the sterilized dung water for liquid fermentation, wherein the bacterial agent is the EM microbial agent for composting produced by Hunan Taigu Ecological Engineering Co., Ltd. The number of effective viable bacteria is ≥8 billion cfu / g, and the bacterial agent contains a variety of functional microorganisms, which can produce protease, amylase, cellulase, ligninase, etc., and are used for the degradation of various raw materials;

[0025] Step 3: After fermentation, the dung is filtered, the filter residue is used for rice and shrimp co-cropping, and the filtra...

Embodiment 2

[0028] The invention provides a method for the comprehensive utilization of breeding waste to prevent and control non-point source pollution, which comprises the following steps:

[0029] Step 1: Pass the feces into the fermenter, add water to adjust, so that the solid content is 20%, and sterilize for 45 minutes at a temperature of 100°C;

[0030] Step 2, adding 2% glucose and 2% bacterial agent to the sterilized dung water to carry out liquid fermentation, wherein the bacterial agent is the EM bacterial agent for compost produced by Hunan Taigu Ecological Engineering Co., Ltd., which effectively activates The number of bacteria is ≥ 8 billion cfu / g. The bacteria agent contains a variety of functional microorganisms, which can produce protease, amylase, cellulase, ligninase, etc., and are used for the degradation of various raw materials;

[0031] Step 3: After fermentation, the dung is filtered, the filter residue is used for rice and crab co-culture, and the filtrate is dis...

Embodiment 3

[0034] The invention provides a method for the comprehensive utilization of breeding waste to prevent and control non-point source pollution, which comprises the following steps:

[0035] Step 1: Feed water into the fermenter, add water to adjust to make the solid content 10%, and sterilize at 140°C for 30 minutes;

[0036] Step 2, add 2% corn flour and 2% bacterial agent in the sterilized dung water, carry out liquid fermentation, wherein said bacterial agent is the EM microbial agent of the compost that Hunan Taigu Ecological Engineering Co., Ltd. produces, effectively The number of viable bacteria is ≥ 8 billion cfu / g. The bacterial agent contains a variety of functional microorganisms, which can produce protease, amylase, cellulase, ligninase, etc., and are used for the degradation of various raw materials;

[0037] Step 3: After fermentation, the dung is filtered, the filter residue is used for rice and crab co-culture, and the filtrate is discharged after being treated i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com