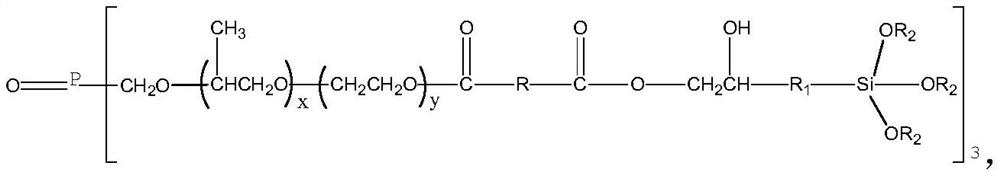

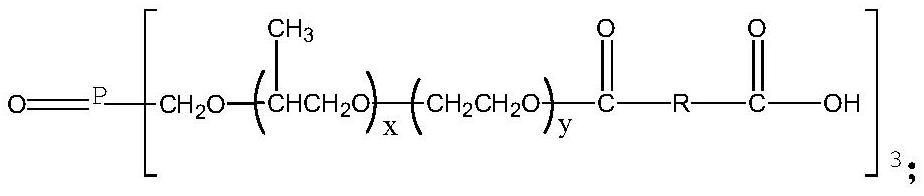

A kind of phosphorus-containing silane-terminated polyether and preparation method thereof

A technology of silane-terminated polyether and glyceryl ether alkoxysilane, which is applied in the direction of polyether adhesives, non-polymer adhesive additives, adhesive types, etc. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

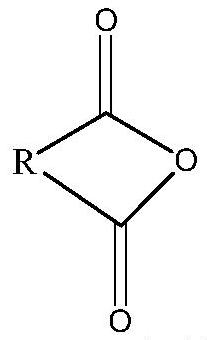

Method used

Image

Examples

Embodiment 1

[0032] Add 140g of trishydroxymethylphosphine oxide (THPO) to the autoclave, after nitrogen replacement, heat up to 90°C, continue to add 140g of propylene oxide, keep warm until the system pressure is 0MPa, heat up to 105°C, and vacuumize at the same time Keep the pressure at -0.1MPa for 1 hour, cool down to 90°C, add 294g of maleic anhydride, and continue the reaction for 6 hours to obtain a carboxyl-terminated phosphorus-containing polyether; continue to raise the temperature to 120°C, add 708g of γ-glycidyl etheroxypropyl trimethoxy Base silane and 1.3g triphenylphosphine (0.1% by weight) catalyst continued to react for 2h; cooled and discharged to obtain phosphorus-containing silane-terminated polyether resin.

Embodiment 2

[0034] Add 140g of trihydroxymethylphosphine oxide (THPO) to the autoclave without adding propylene oxide and / or ethylene oxide, raise the temperature to 150°C, add 504g of methylhexahydrophthalic anhydride, and continue the reaction for 2h to obtain tricarboxylic Phosphine oxide; cool down to 120°C, add 708g of γ-glycidyl etheroxypropyl trimethoxysilane and 1.3g of quaternary ammonium salt (0.1% by weight) catalyst to continue the reaction for 2h; cool down and discharge to obtain phosphorus-containing silane-capped resin.

Embodiment 3

[0036] Add 140g of trishydroxymethylphosphine oxide (THPO) to the autoclave. After nitrogen replacement, heat up to 100°C, continue to add 500g of the mixture (400g of propylene oxide and 100g of ethylene oxide), and keep warm until the system pressure is 0MPa until the temperature is raised to 105°C, while evacuating until the pressure is 0.02MPa and maintaining for 1h, add 444g of phthalic anhydride at this temperature, and continue the reaction for 3h to obtain a carboxyl-terminated phosphorus polyether; continue to raise the temperature to 110°C, add 834g γ-glycidyl etheroxypropyltriethoxysilane and 9.6g triphenylphosphine (0.5% by weight) catalyst continued to react for 2 hours; the temperature was lowered and the material was discharged to obtain a phosphorus-containing silane-terminated polyether resin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com