Self-lubricating wear-resistant PTFE (polytetrafluoroethylene) composite material and preparation method thereof

A composite material, PTFE technology, applied in the field of self-lubricating and wear-resistant PTFE composite materials and its preparation, can solve the problems of large cold flow, poor dimensional stability, insufficient wear resistance, etc., to improve wear resistance and high temperature Abrasion resistance and the effect of extending the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

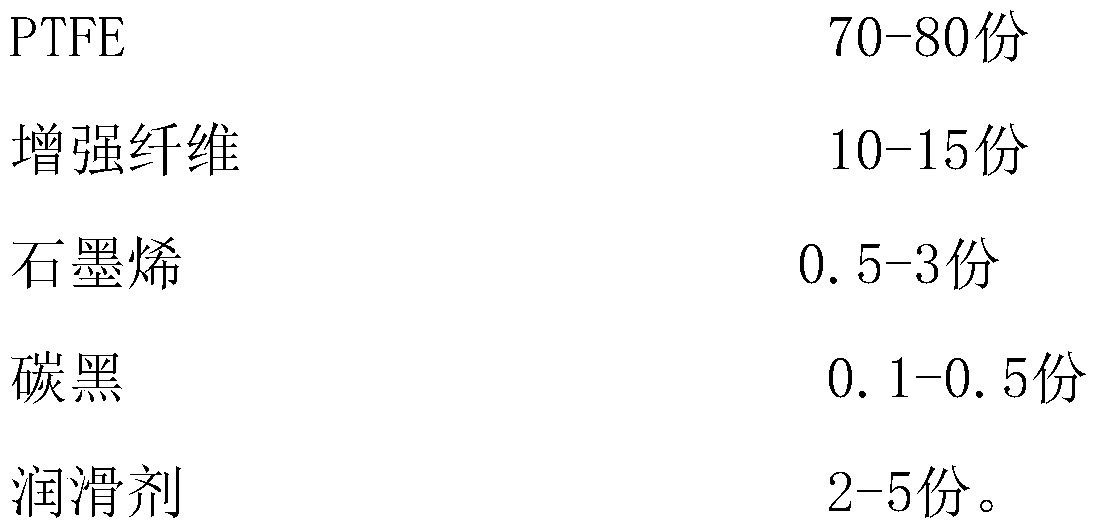

[0035] A self-lubricating wear-resistant PTFE composite material, comprising the following raw materials in parts by weight:

[0036]

[0037] The density of the PTFE is 2.16g / cm 3 , the PTFE is a polytetrafluoroethylene powder with a mesh number of 500.

[0038] The reinforcing fiber is a mixture of carbon fiber and alumina fiber at a weight ratio of 7:1.5; the reinforcing fiber is fiber powder with a mesh number of 600.

[0039] The graphene is graphene with a mesh number of 1300.

[0040] The graphene is graphene oxide treated with a silane coupling agent.

[0041] The silane coupling agent is γ-aminopropyltriethoxysilane.

[0042] The lubricant is formed by mixing tungsten disulfide and boron nitride at a weight ratio of 2.5:1.

[0043] The preparation method of above-mentioned self-lubricating wear-resistant PTFE composite material, comprises the steps:

[0044] (A1), take by weight PTFE, reinforcing fiber, graphene, carbon black and lubricant, standby;

[0045] ...

Embodiment 2

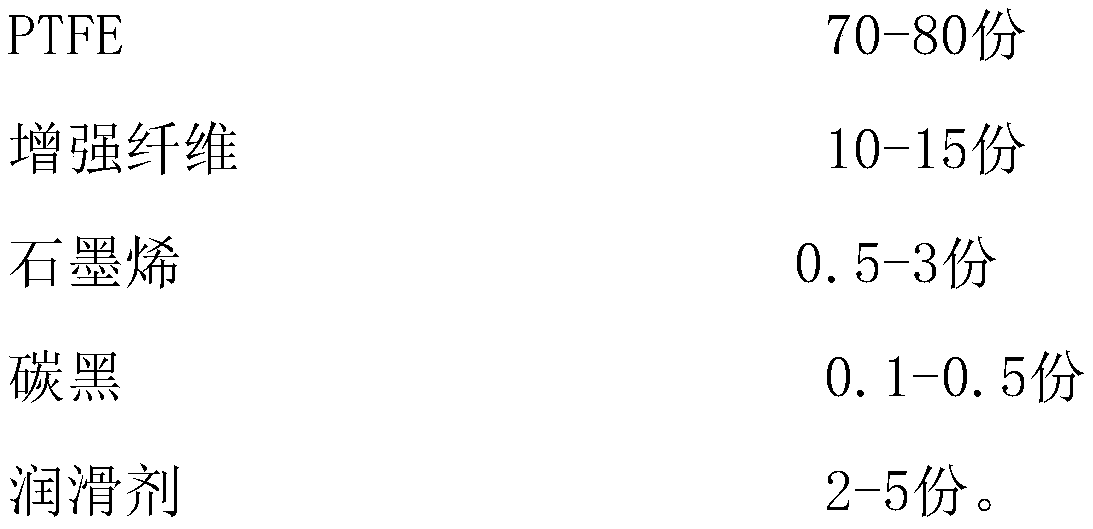

[0050] A self-lubricating wear-resistant PTFE composite material, comprising the following raw materials in parts by weight:

[0051]

[0052] The density of the PTFE is 2.1g / cm 3 , the PTFE is a polytetrafluoroethylene powder with a mesh number of 300.

[0053] The reinforcing fiber is formed by mixing carbon fiber and alumina fiber at a weight ratio of 5:1; the reinforcing fiber is fiber powder with a mesh number of 500.

[0054] The graphene is graphene with a mesh number of 1200.

[0055] The graphene is graphene oxide treated with a silane coupling agent.

[0056] The silane coupling agent is γ-(2,3-glycidoxy)propyltrimethoxysilane.

[0057] The lubricant is formed by mixing tungsten disulfide and boron nitride at a weight ratio of 2:1.

[0058] The preparation method of above-mentioned self-lubricating wear-resistant PTFE composite material, comprises the steps:

[0059] (A1), take by weight PTFE, reinforcing fiber, graphene, carbon black and lubricant, standby; ...

Embodiment 3

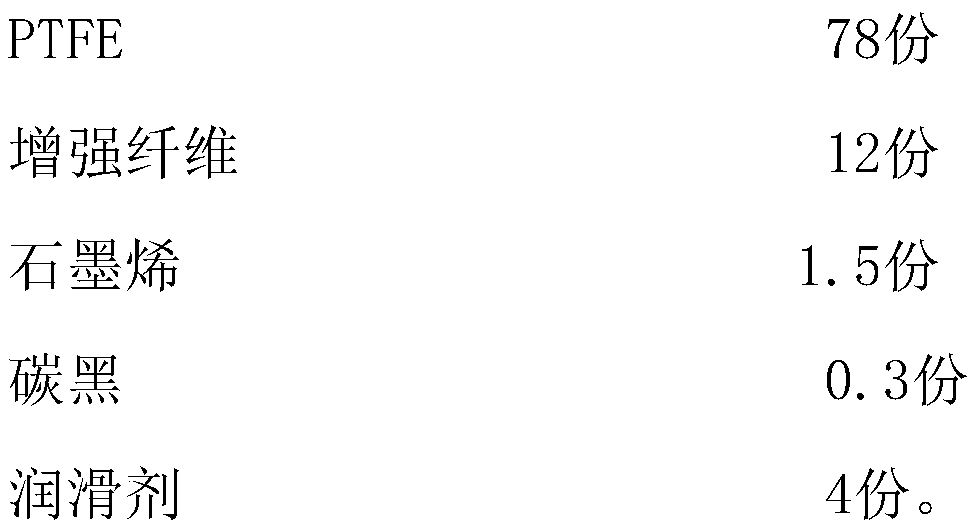

[0065] A self-lubricating wear-resistant PTFE composite material, comprising the following raw materials in parts by weight:

[0066]

[0067] The density of the PTFE is 2.2g / cm 3 , the PTFE is a polytetrafluoroethylene powder with a mesh number of 600.

[0068] The reinforcing fiber is formed by mixing carbon fiber and alumina fiber at a weight ratio of 8:2; the reinforcing fiber is fiber powder with a mesh number of 800.

[0069] The graphene is graphene with a mesh number of 1500.

[0070] The graphene is graphene oxide treated with a silane coupling agent.

[0071] The silane coupling agent is γ-mercaptopropyltriethoxysilane.

[0072] The lubricant is formed by mixing tungsten disulfide and boron nitride at a weight ratio of 3:1.

[0073] The preparation method of above-mentioned self-lubricating wear-resistant PTFE composite material, comprises the steps:

[0074] (A1), take by weight PTFE, reinforcing fiber, graphene, carbon black and lubricant, standby;

[0075...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com