Intelligent response self-repairing anticorrosive coating material and preparation method thereof

An anti-corrosion coating and self-repairing technology, applied in anti-corrosion coatings, coatings, epoxy resin coatings, etc., can solve the problems of capsule core material deactivation, large microcapsule particle size, poor binding force, etc., to ensure activity, Effects of improving bonding performance and improving anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

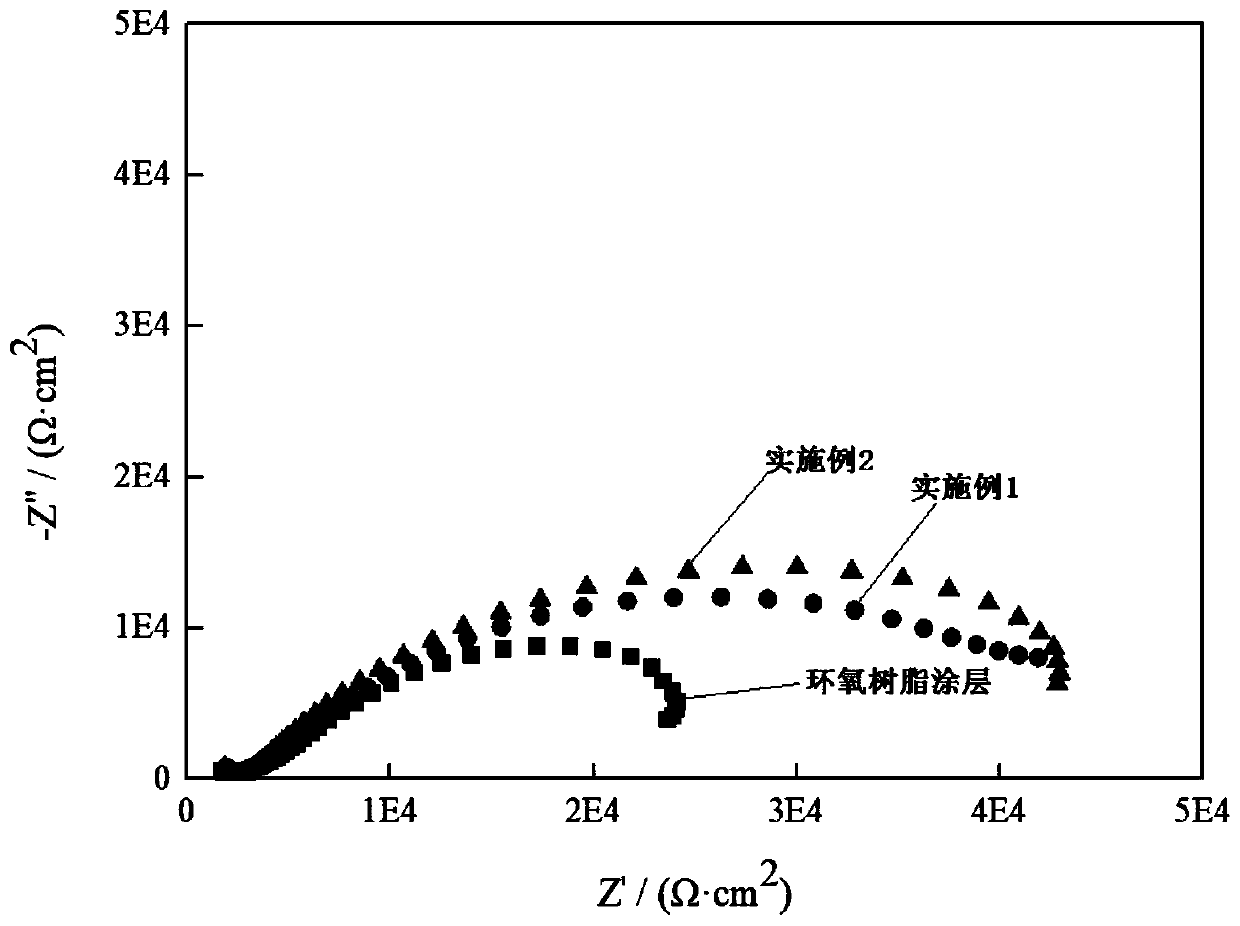

Embodiment 1

[0036] A method for preparing an intelligent response self-repairing anti-corrosion coating material, comprising the following steps:

[0037] S1. Add zinc acetate to the triethylene glycol solution, the concentration of zinc acetate is 3mM; heat to 160 and keep the temperature for 30min under vigorous stirring, after cooling to room temperature, centrifuge and collect the solid product to obtain porous zinc oxide nano powder;

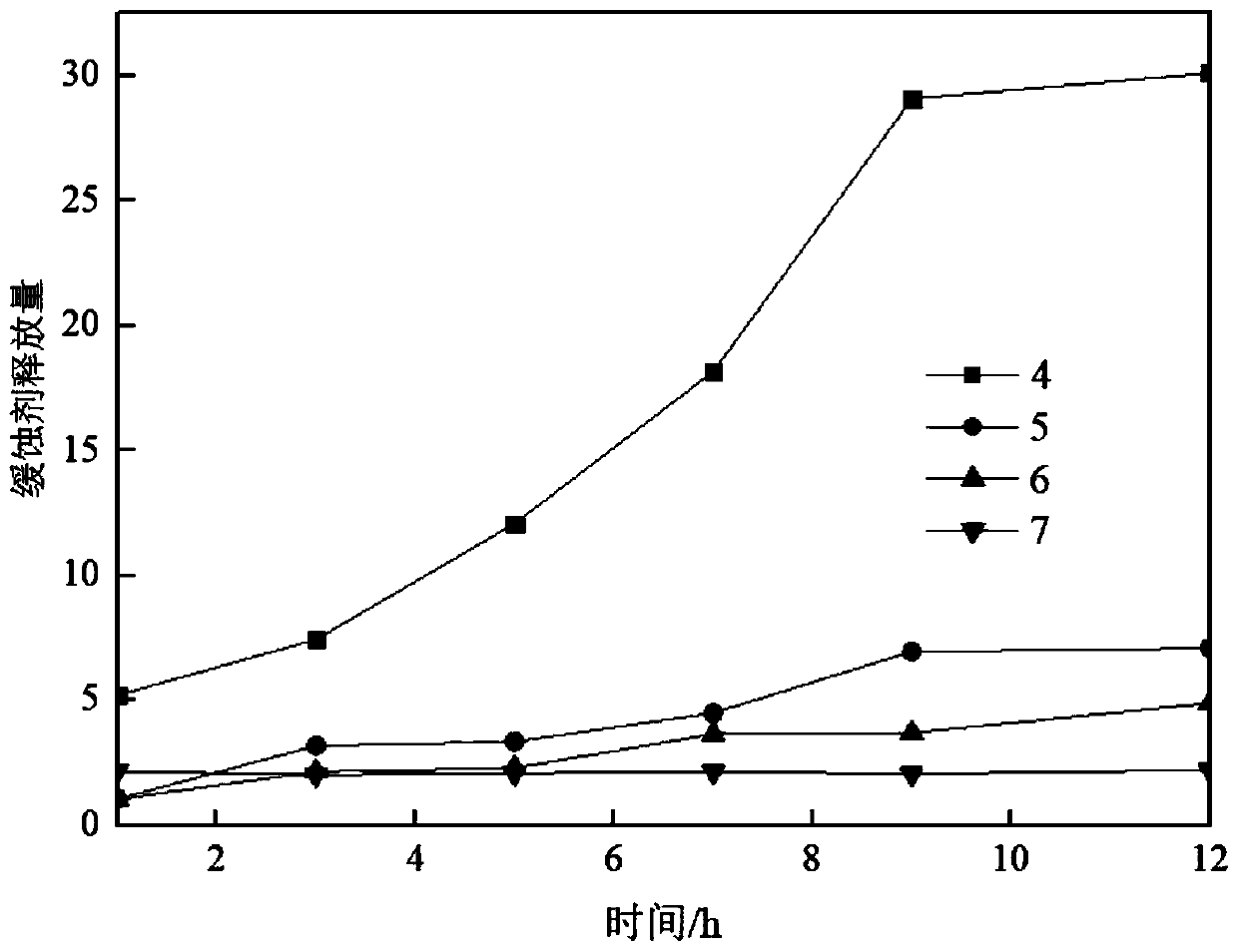

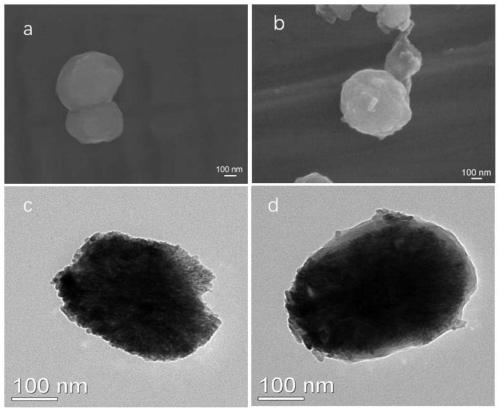

[0038] S2. The above-mentioned porous zinc oxide nanopowder is uniformly dispersed in deionized water to obtain solution A, and the mass concentration of porous zinc oxide in solution A is 25mg / mL; the corrosion inhibitor benzotriazole is dissolved in deionized water to obtain Solution B, the mass concentration of corrosion inhibitor in solution B is 16mg / mL; mix solution A and solution B and stir at low speed for 5h; then add 2mg / mL dimethylimidazole solution and react for 30min to generate ZIF on the surface of porous zinc oxide -8 film to encapsula...

Embodiment 2

[0041] A method for preparing an intelligent response self-repairing anti-corrosion coating material, comprising the following steps:

[0042] S1. Add zinc acetate to the triethylene glycol solution, the concentration of zinc acetate is 3mM; heat to 160 and keep the temperature for 30min under vigorous stirring, after cooling to room temperature, centrifuge and collect the solid product to obtain porous zinc oxide nano powder;

[0043] S2. The above-mentioned porous zinc oxide nanopowder is uniformly dispersed in deionized water to obtain solution A, and the mass concentration of porous zinc oxide in solution A is 20mg / mL; the corrosion inhibitor benzotriazole is dissolved in deionized water to obtain Solution B, the mass concentration of corrosion inhibitor in solution B is 16mg / mL; mix solution A and solution B and stir at low speed for 5h; then add 2mg / mL dimethylimidazole solution and react for 30min to generate ZIF on the surface of porous zinc oxide -8 film to encapsula...

Embodiment 3

[0046] A method for preparing an intelligent response self-repairing anti-corrosion coating material, comprising the following steps:

[0047] S1. Add zinc acetate into the triethylene glycol solution, the concentration of zinc acetate is 5mM; heat to 180°C under vigorous stirring and keep the temperature for 50min, after cooling to room temperature, centrifuge and collect the solid product to obtain porous zinc oxide Nano powder;

[0048] S2. The above-mentioned porous zinc oxide nanopowder is uniformly dispersed in deionized water to obtain solution A, and the mass concentration of porous zinc oxide in solution A is 20mg / mL; the corrosion inhibitor benzotriazole is dissolved in deionized water to obtain Solution B, the mass concentration of corrosion inhibitor in solution B is 20mg / mL; mix solution A and solution B and stir at low speed for 3h; then add 6mg / mL dimethylimidazole solution to react for 50min, and generate ZIF on the surface of porous zinc oxide -8 film to enca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com