Personalized 3D printing porous titanium-based tantalum-coating bone fracture plate and preparation method thereof

A 3D printing, porous titanium technology, applied in the direction of outer plate, internal bone synthesis, medical science, etc., can solve the problems of shape mismatch, secondary extraction, stress shielding, etc., to avoid stress shielding, improve biological activity, and good plasticity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

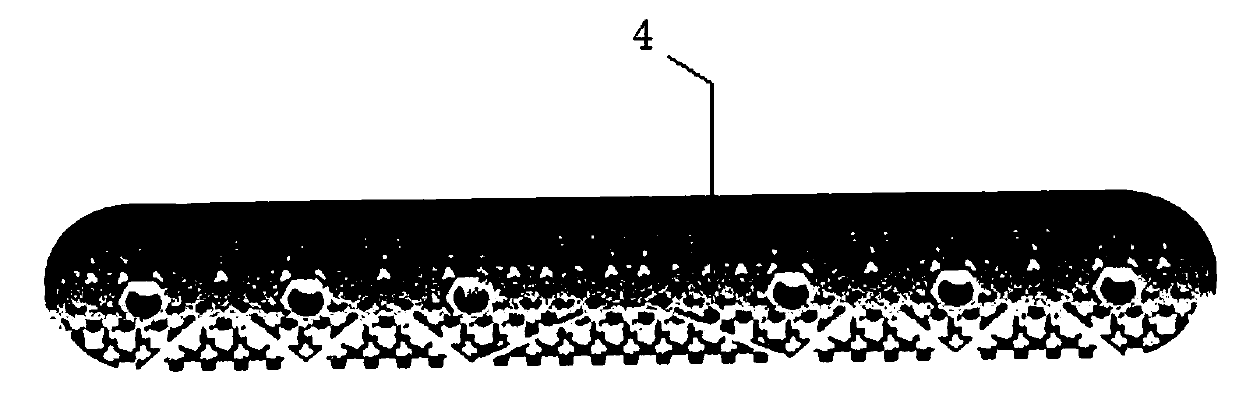

[0047] A personalized 3D printed porous titanium-based tantalum metal-coated bone plate with osteoinductive activity, which uses titanium metal powder as a substrate, and a porous titanium-based bone plate with a void structure made by 3D printing is formed with a tantalum coating. The layer is prepared.

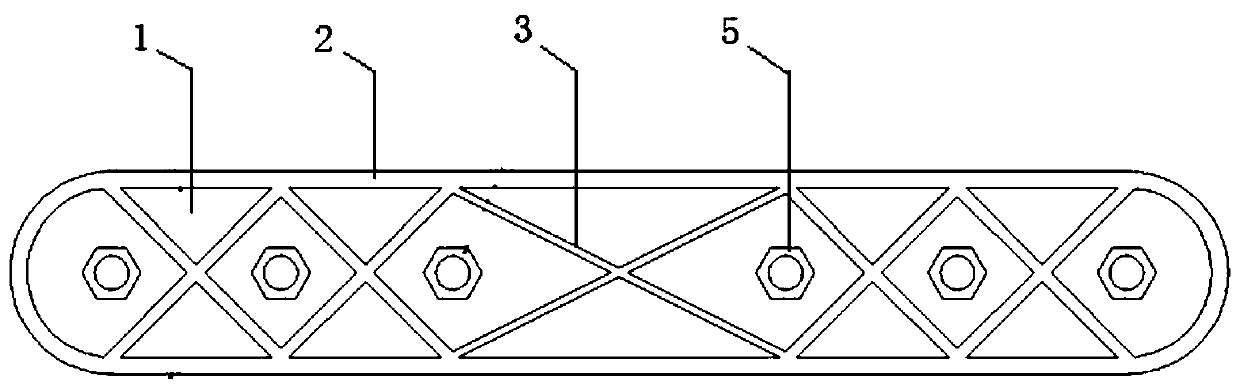

[0048] Such as figure 1 with figure 2 As shown, the porous titanium-based bone plate includes a main body, and the main body includes an outer reinforcing rib located on the peripheral edge of the main body, an inner reinforcing rib located inside the outer reinforcing rib, a void structure, and a screw hole. The outer reinforcing ribs are in a continuous structure to form the edge of the body, and the inner reinforcing ribs are in a mesh structure to improve the mechanical strength of the bone plate. The void structure is distributed between the outer reinforcement ribs, the inner reinforcement ribs and the screw holes, and is composed of internally connected diamond-shaped p...

Embodiment 2

[0052] Using high-purity titanium powder (spherical powder, particle size 15μm-30μm) as raw material, it is processed and manufactured by 3D printing to prepare personalized 3D printed tantalum metal coated porous titanium bone plate, which specifically includes the following steps:

[0053] (1) Understand the anatomical structure of the patient's fracture through CT scan, and reconstruct the CT scan data into a 3D model (ie 3D geometric image);

[0054] (2) Use Auto CAD, Pro E, Magics software to design the shape and void structure of the personalized bone plate, and obtain the three-dimensional geometric model of the porous target bone plate (such as figure 2 Shown) to further obtain the .stl format file of the three-dimensional geometric model of the porous target bone plate;

[0055] (3) such as figure 2 The 3D printing process of the porous bone plate shown is: merge the titanium metal parameter package with the .stl file on the Building Processing interface to obtain the .mtt ...

Embodiment 3

[0066] A male goat weighing about 20kg was selected as the experimental animal, and the anatomical structure of the goat's tibia was understood through CT scan, and the CT scan data was reconstructed into a 3D model (ie, geometric image). Use Auto CAD, Pro E, Magics software to design the shape and void structure of the personalized bone plate, obtain the three-dimensional geometric model of the porous target bone plate, and further obtain the .stl format file of the three-dimensional geometric model of the porous target bone plate. Then merge the titanium metal parameter package with the .stl file in the Building Processing interface to obtain the .mtt format file that can be recognized by the 3D printer device, and input the .mtt format file into the 3D printing device for printing. The width of the bone plate It is 1.2cm and the length is 10cm; the diameter of the screw is 2.7mm, and the length is 14mm. Then, tantalum metal was deposited on the prepared porous titanium bone ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com