Preparation method for enhancing interface performance of basalt

A technology of interface performance and basalt, applied in textiles and papermaking, conjugated artificial filament, filament/thread forming, etc., can solve problems such as poor interface adhesion, and achieve the effect of complete structure, low cost and less waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A preparation method for enhancing the interface performance of basalt, specifically comprising the following steps:

[0032] Step 1. Put the basalt fiber in absolute ethanol for ultrasonic cleaning for 30 minutes, then wash it with deionized water until the supernatant liquid is neutral, put it in a 40°C oven and dry it for 6 hours to obtain the cleaned basalt fiber;

[0033] Step 2, mixing PAN as the solute of the spinning solution and the solvent N,N-dimethylformamide to obtain a spinning solution, the mass concentration of the spinning solution is 6%;

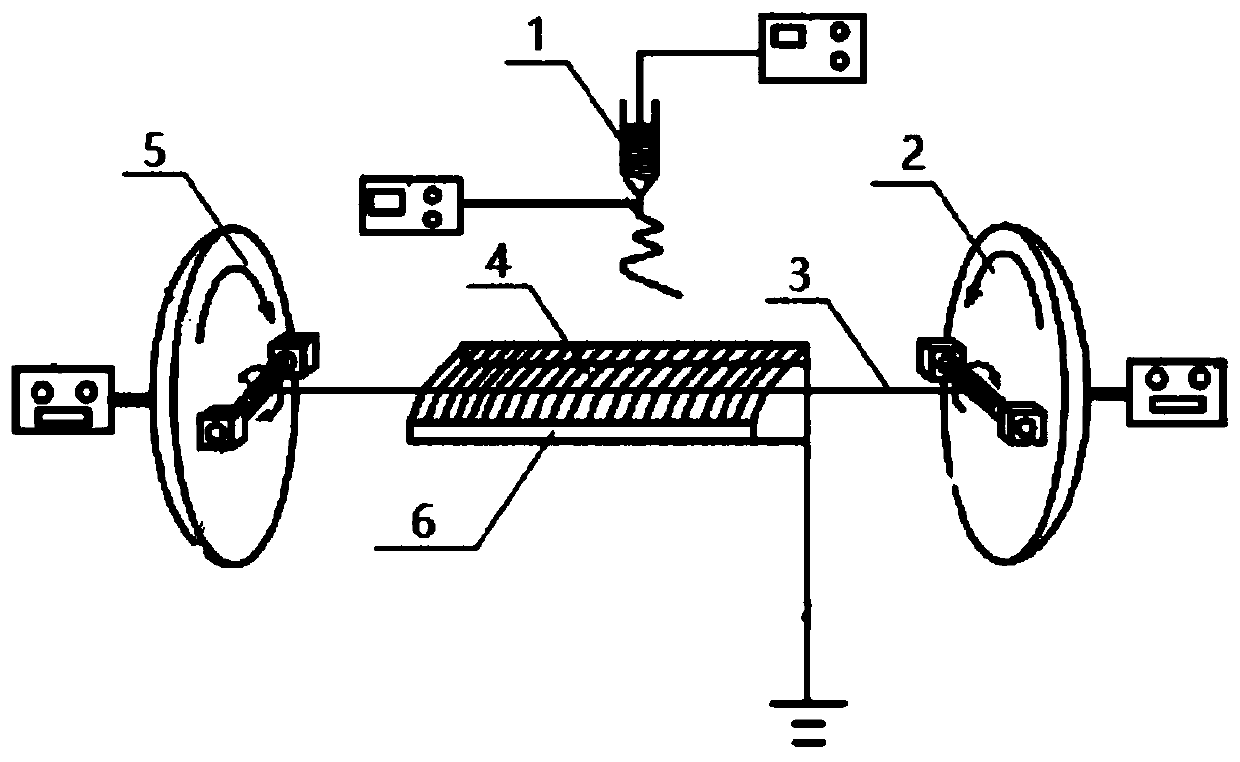

[0034] Step 3. Use a syringe to extract 6ml of the spinning solution, use the cleaned basalt fiber as the core layer, and prepare PAN-basalt nano-coated fiber by electrospinning. The ambient temperature of the electrospinning is 20±2°C, The relative humidity is 60±5%;

[0035] Specifically, in step 3, follow the steps below:

[0036] Step 3.1: Place the cleaned basalt fiber 3 as the core layer about 1 mm above the ...

Embodiment 2

[0046] A preparation method for enhancing the interface performance of basalt, specifically comprising the following steps:

[0047] Step 1. Put the basalt fiber in absolute ethanol for ultrasonic cleaning for 30 minutes, then wash it with deionized water until the supernatant is neutral, put it in a 40°C oven and dry it for 7 hours to obtain the cleaned basalt fiber;

[0048] Step 2, mixing PAN as the solute of the spinning solution and the solvent N,N-dimethylformamide to obtain a spinning solution, the mass concentration of the spinning solution is 12%;

[0049] Step 3. Extract 7ml of the spinning solution with a syringe, use the cleaned basalt fiber as the core layer, and prepare PAN-basalt nano-coated fiber by electrospinning. The electrospinning ambient temperature is 20±2°C, The relative humidity is 60±5%;

[0050] Specifically, in step 3, follow the steps below:

[0051] Step 3.1: Place the cleaned basalt fiber 3 as the core layer about 1 mm above the two metal sheet...

Embodiment 3

[0061] A preparation method for enhancing the interface performance of basalt, specifically comprising the following steps:

[0062] Step 1. Put the basalt fiber in absolute ethanol for ultrasonic cleaning for 30 minutes, then wash it with deionized water until the supernatant liquid is neutral, and dry it in a 40°C oven for 8 hours to obtain the cleaned basalt fiber;

[0063] Step 2, mixing PAN as the solute of the spinning solution and the solvent N,N-dimethylformamide to obtain a spinning solution, the mass concentration of the spinning solution is 20%;

[0064] Step 3. Extract 8ml of the spinning solution with a syringe, use the cleaned basalt fiber as the core layer, and prepare PAN-basalt nano-coated fiber by electrospinning method. The electrospinning ambient temperature is 20±2°C, The relative humidity is 60±5%;

[0065] Specifically, in step 3, follow the steps below:

[0066] Step 3.1: Place the cleaned basalt fiber 4 as the core layer about 1 mm above the two meta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com