Environment-friendly dedusting viscous wiping rag and preparation method thereof

A sticky and environmentally friendly technology, applied in the field of cleaning cloth, can solve the problems of environmental and operator injury, non-compliance with the development requirements of the green environmental protection era, human injury and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

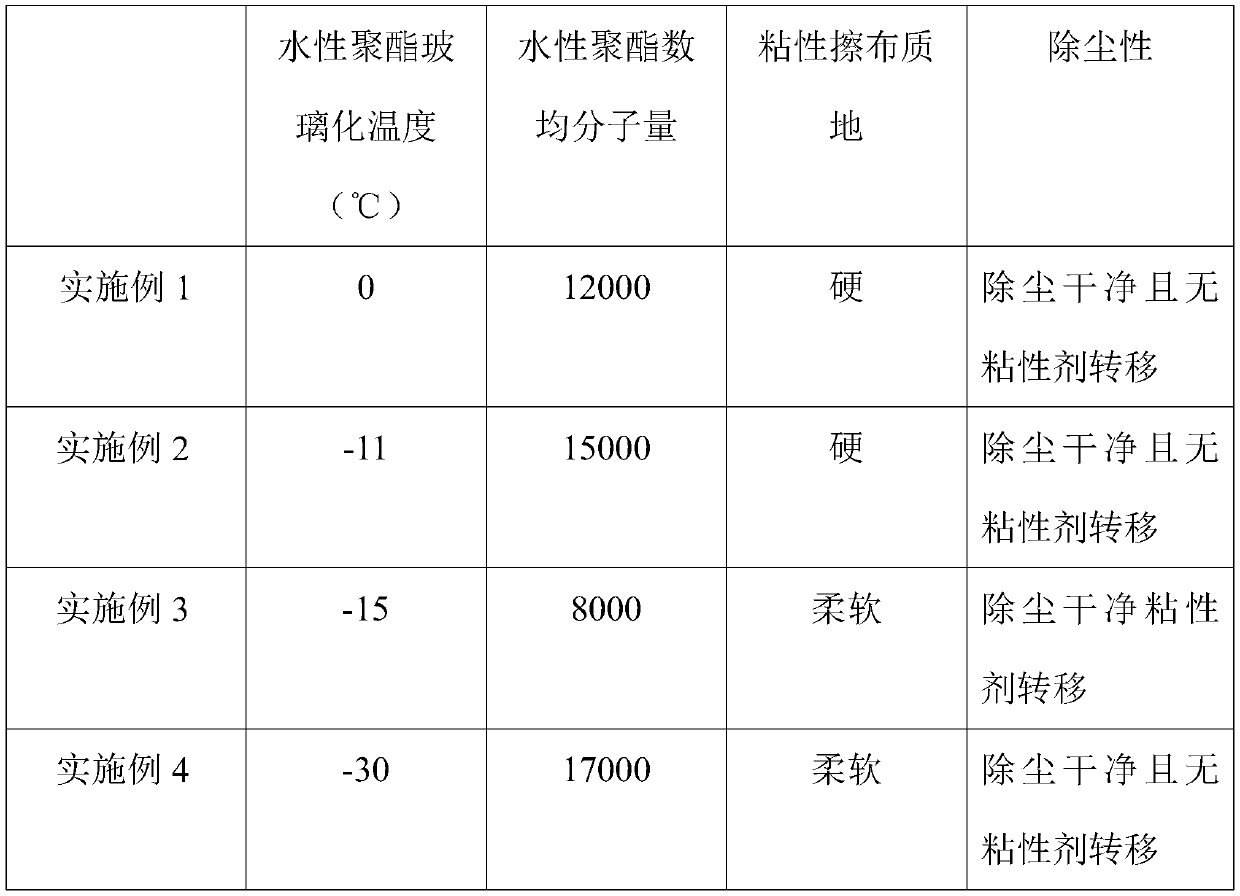

Embodiment 1

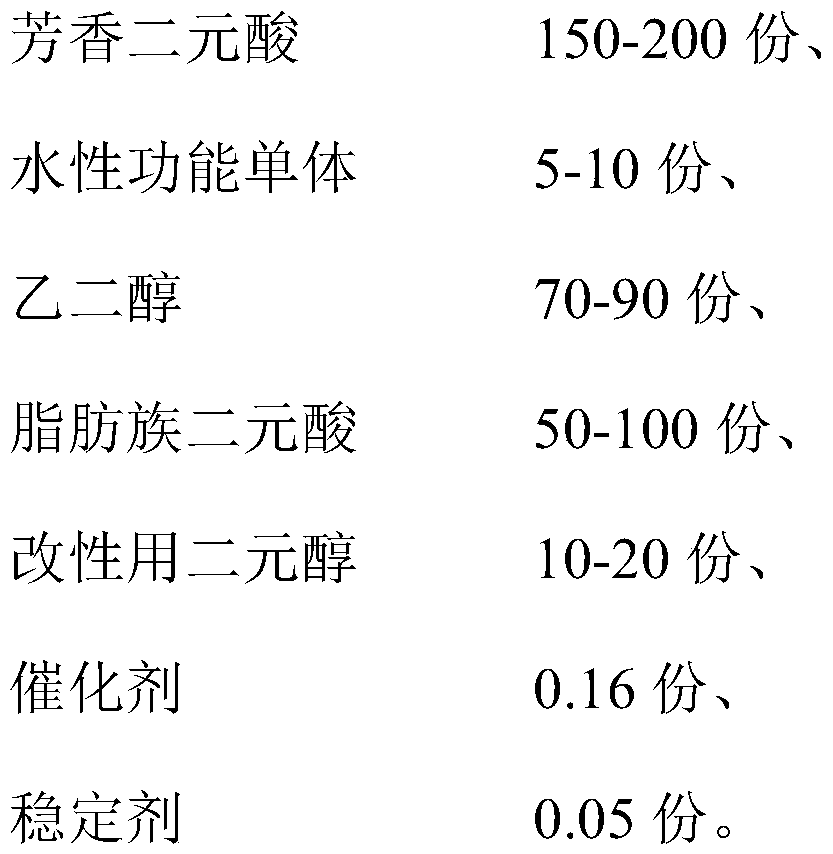

[0021] Weighing:

[0022] Aromatic dibasic acid: 200g terephthalic acid,

[0023] Water-based functional monomer: 10g sodium isophthalic acid-5-sulfonate,

[0024] Ethylene glycol 90g,

[0025] Aliphatic dibasic acid: adipic acid 50g,

[0026] Dihydric alcohol for modification: neopentyl glycol 10g,

[0027] Catalyst: ethylene glycol antimony 0.16g,

[0028] Stabilizer: 0.05 g of triphenyl phosphite.

[0029] Raw materials except the catalyst and stabilizer are added to a 1L polyester reactor at one time, and the esterification reaction is carried out at 300KPa and 240°C. After the esterification effluent reaches 90% of the theoretical value, the catalyst and stabilizer are added to the reactor. Then it was slowly pumped to a high vacuum, polycondensed under vacuum for 2 hours at 270° C., stopped the reaction, discharged, and cooled to obtain a low vitrification water-soluble polyester.

[0030] Heat to dissolve the low-vitrification water-soluble polyester in water, the...

Embodiment 2

[0032] Weighing:

[0033] Aromatic dibasic acid: 150g terephthalic acid, 50g isophthalic acid,

[0034] Water-based functional monomer: 5g of 2-sodium sulfonate terephthalic acid,

[0035] Ethylene glycol 70g,

[0036] Aliphatic dibasic acid: adipic acid 100g,

[0037] Modification dibasic alcohol: neopentyl glycol 20g,

[0038] Catalyst: tetrabutyl titanate 0.16g,

[0039] Stabilizer: 0.05 g of trimethyl phosphate.

[0040] Raw materials except the catalyst and stabilizer are added to a 1L polyester reactor at one time, and the esterification reaction is carried out at 300KPa and 240°C. After the esterification effluent reaches 90% of the theoretical value, the catalyst and stabilizer are added to the reactor. Then it was slowly pumped to a high vacuum, polycondensed under vacuum for 2 hours at 270° C., stopped the reaction, discharged, and cooled to obtain a low vitrification water-soluble polyester.

[0041] Heat to dissolve the low-vitrification water-soluble polyest...

Embodiment 3

[0043] Weighing:

[0044] Aromatic dibasic acid: 190g terephthalic acid,

[0045] Water-based functional monomer: 10g sodium isophthalic acid-5-sulfonate,

[0046] Ethylene glycol 80g,

[0047] Aliphatic dibasic acid: sebacic acid 100g,

[0048] Diol for modification: 10g of 2-methylpropanediol,

[0049] Catalyst: C-94 0.16g,

[0050] Stabilizer: antioxidant 1010 0.05g.

[0051] Raw materials except the catalyst and stabilizer are added to a 1L polyester reactor at one time, and the esterification reaction is carried out at 300KPa and 240°C. After the esterification effluent reaches 90% of the theoretical value, the catalyst and stabilizer are added to the reactor. Then it was slowly pumped to a high vacuum, polycondensed under vacuum for 2 hours at 270° C., stopped the reaction, discharged, and cooled to obtain a low vitrification water-soluble polyester.

[0052] Heat to dissolve the low-vitrification water-soluble polyester in water, then immerse the non-woven fabric ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com