Improved method for measuring fatty acid composition of sorbitan monostearate

A determination method and fatty acid technology, which can be used in measurement devices, instruments, scientific instruments, etc., and can solve the problem of high error rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

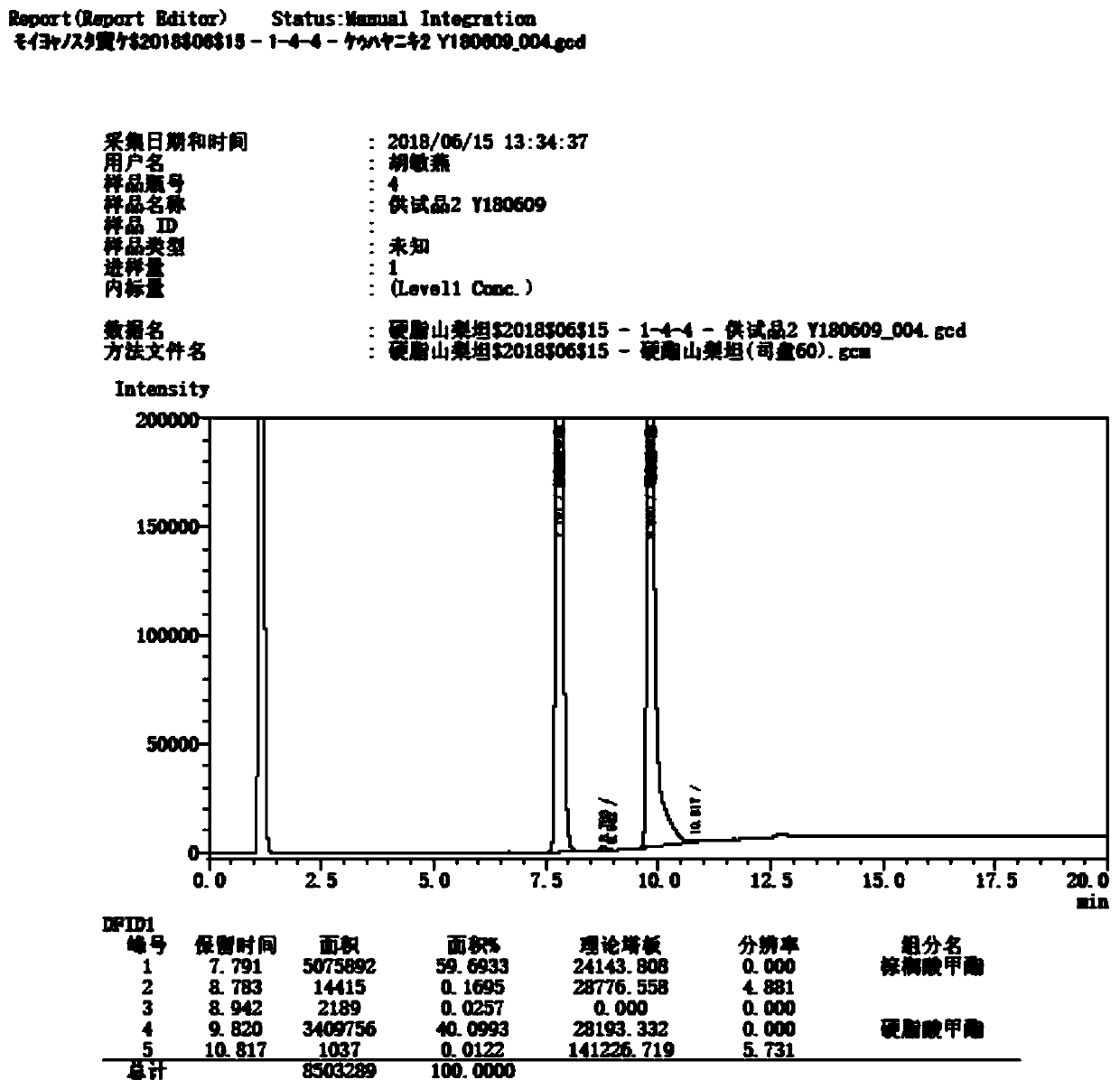

[0016] Accurately weigh 0.6000g and 0.4000g of standard palmitic acid and stearic acid, and react with an appropriate amount of raw material sorbitan to obtain a sample of Span 60 through esterification, take 0.1g of sample 1, and test sample 1 according to the following method:

[0017] Take 0.1g of this product, put it in a 50ml round bottom flask, add 4ml of 0.5mol / L potassium hydroxide methanol solution, heat and reflux in a water bath at 65°C for 30 minutes, let it cool, add 5ml of 14% boron trifluoride methanol solution, Heat and reflux in a 65°C water bath for 5 minutes, let cool, add 5ml of n-hexane, continue to heat and reflux in a 65°C water bath for 5 minutes, let cool, add 10ml of saturated sodium chloride solution, shake well, let stand to separate layers, and take the upper layer Liquid, dried over anhydrous sodium sulfate; test according to gas chromatography (general rule 0521). Use polyethylene glycol as the fixed liquid capillary column as the chromatographic...

Embodiment 2

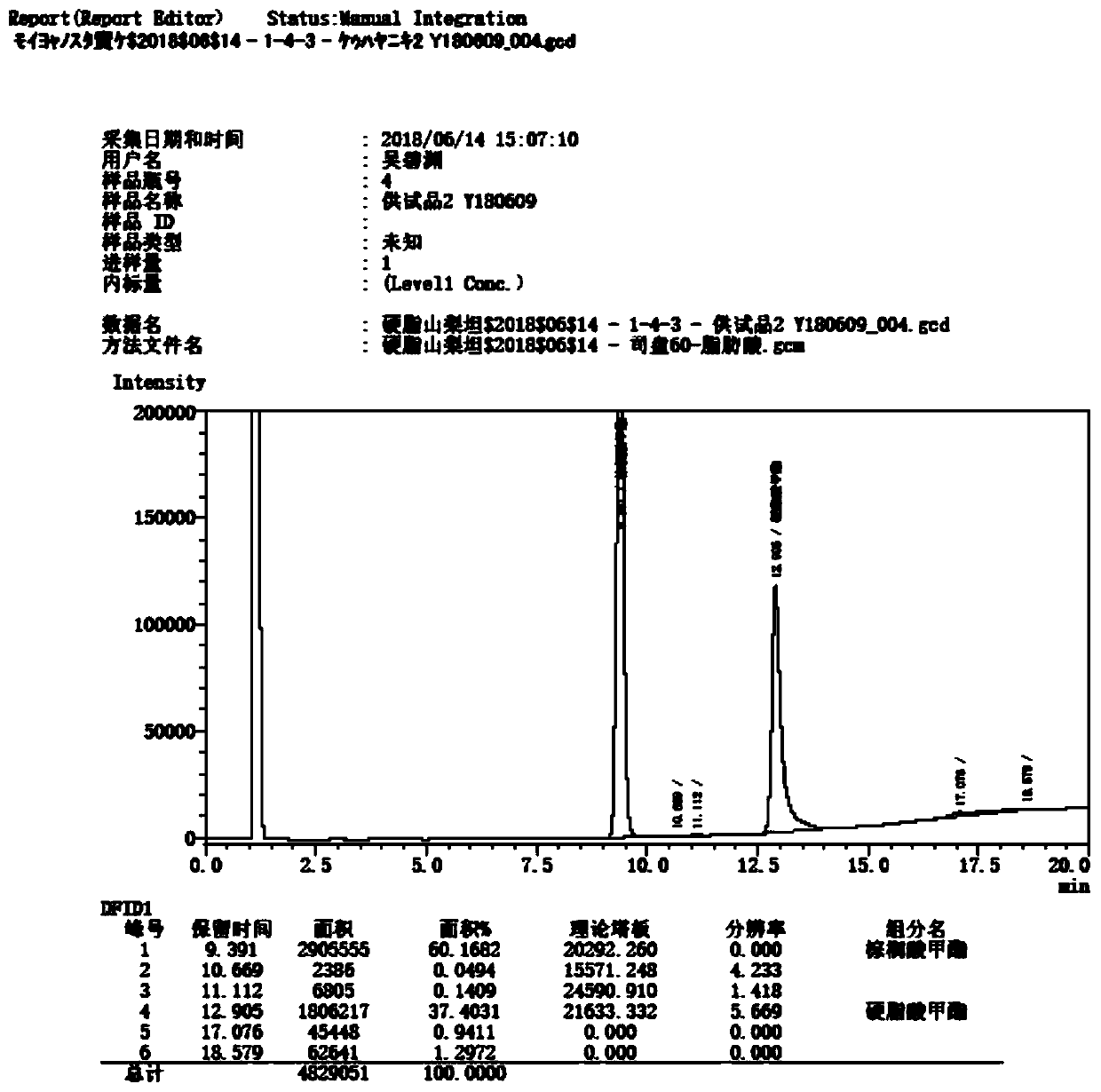

[0023] Test sample 2 (with embodiment 1) as follows:

[0024] Chinese Pharmacopoeia (2015 edition) method:

[0025] Take 0.1g of this product, put it in a 50ml round bottom flask, add 4ml of 0.5mol / L potassium hydroxide methanol solution, heat and reflux in a water bath at 65°C for 10 minutes, let it cool, add 5ml of 14% boron trifluoride methanol solution, Heat and reflux in a water bath at 65°C for 2 minutes, let cool, add 5ml of n-hexane, continue to heat and reflux in a water bath at 65°C for 1 minute, let cool, add 10ml of saturated sodium chloride solution, shake well, let stand to separate layers, and take the upper layer Liquid, dried over anhydrous sodium sulfate; test according to gas chromatography (general rule 0521). Use polyethylene glycol as the fixed liquid capillary column as the chromatographic column, the initial temperature is 150°C, maintain for 3 minutes, increase the temperature to 220°C at a rate of 5°C per minute, and maintain for 10 minutes; the temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com