Acetylacetone gas sensitive material, manufacturing method and application thereof

A gas-sensitive material, acetylacetone technology, which is applied in the direction of analyzing materials, analyzing gas mixtures, and the structural details of gas analyzers, can solve problems such as poor detection sensitivity and selectivity, achieve a wide detection range, promote transmission and diffusion, reduce The effect of the barrier

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The second aspect of the present invention provides a kind of preparation method of acetylacetone gas sensitive material, comprises the steps:

[0035] 1) Weigh the zinc source, hexamethylenetetramine and graphene oxide, add them into deionized water, ultrasonicate, stir until dissolved, and form a solution;

[0036] 2) Transfer the solution prepared in step 1) to a stainless steel autoclave for hydrothermal reaction, and collect the precipitate after the reaction;

[0037] 3) drying the above precipitate to obtain a dry gray powder;

[0038] 4) Put the above powder into a calciner for heat treatment to obtain a finished product.

[0039] Hexamethylenetetramine decomposes under hydrothermal conditions to produce OH - , Zn source dissociates Zn in water 2+ ,OH - with Zn 2+ The reaction produces Zn(OH) 2 , Zn(OH) 2 Thermally decomposed into ZnO. Therefore, hexamethylenetetramine provides OH - .

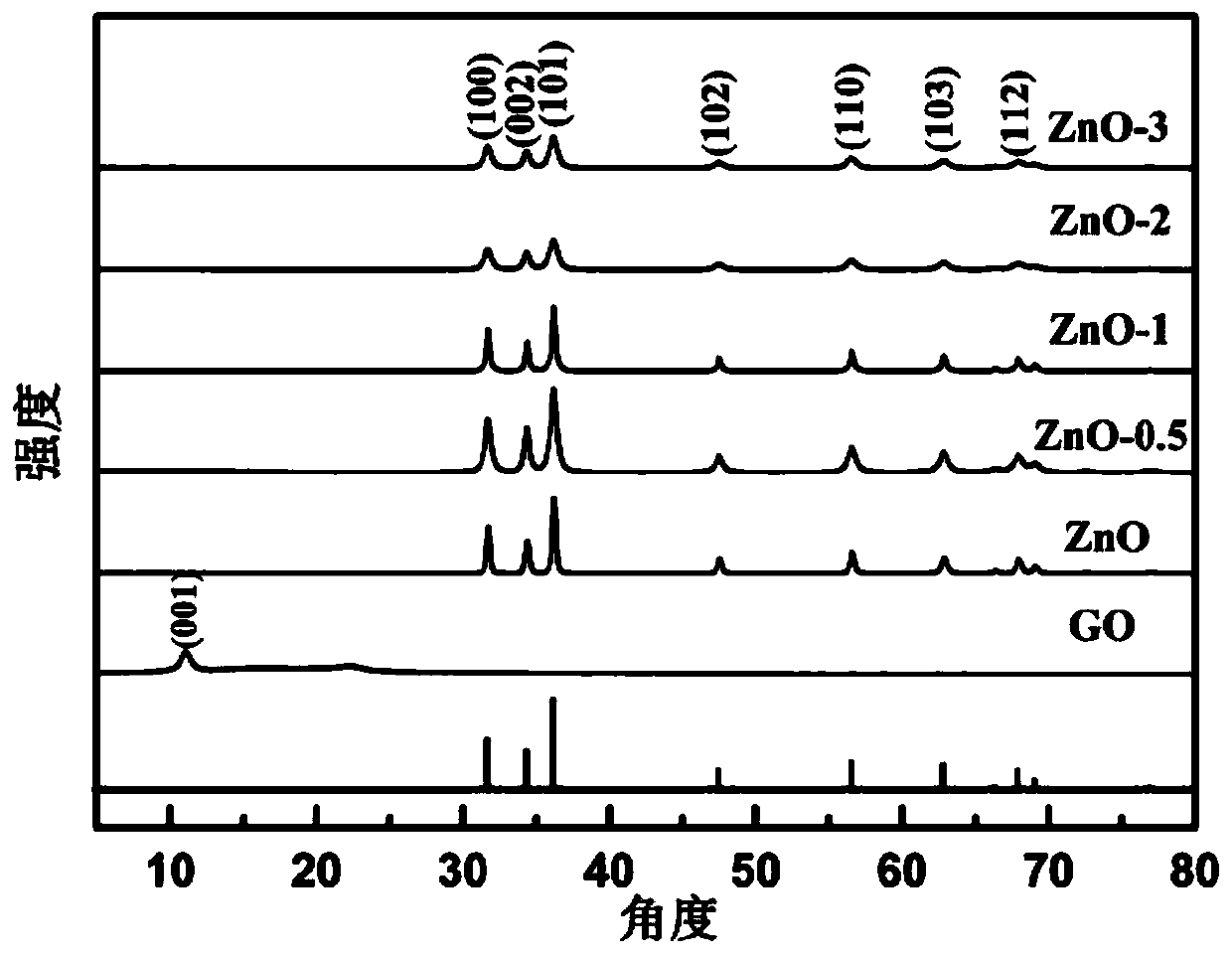

[0040]In some embodiments, the zinc source is zinc nitrate, zinc a...

Embodiment 1

[0052] 1) Weigh zinc nitrate hexahydrate, hexamethylenetetramine and graphene oxide according to the mass ratio of 185:86:2, add them to deionized water, the mass ratio of deionized water to graphene oxide is 2500:1, ultrasonic, Stir until all dissolve and disperse to form a solution.

[0053] 2) Transfer the solution prepared in step 1) of the preparation to a stainless steel high-pressure reactor for hydrothermal reaction. The hydrothermal temperature is 150°C, and the reaction time is 8 hours. After the reaction, use a centrifuge to collect the precipitate at 8000r / min;

[0054] 3) Drying the collected precipitate at a drying temperature of 60° C. and a drying time of 48 hours to completely evaporate the water to obtain a zinc oxide precursor.

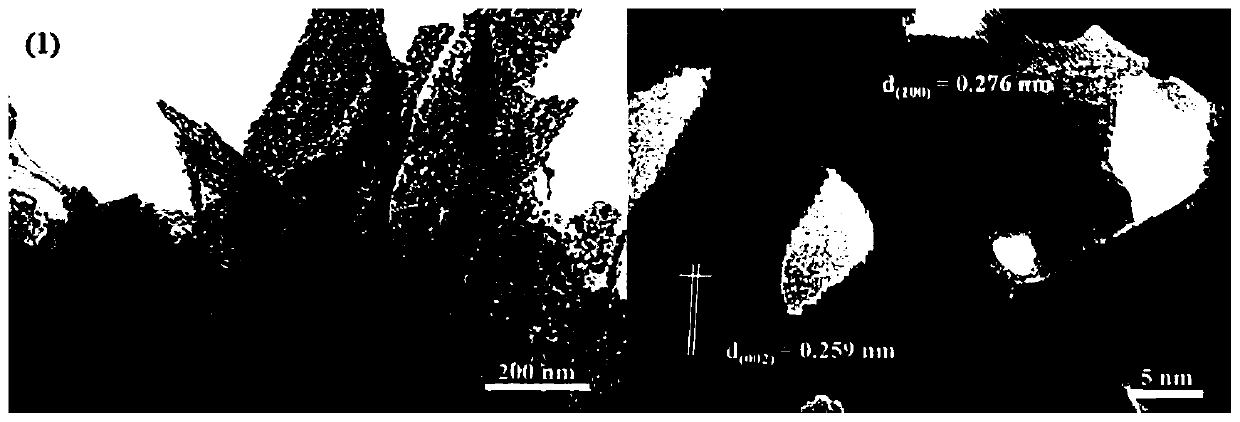

[0055] 4) Put the above powder into a calcination furnace for heat treatment. The box-type silicon carbide rod muffle furnace heats up to 450°C at a rate of 2°C / min, and then keeps it for 2 hours. Finally, take out the ultra-thin po...

Embodiment 2

[0059] 1) Weigh zinc nitrate hexahydrate, hexamethylenetetramine and graphene oxide according to the mass ratio of 185:120:1, add them to deionized water, the mass ratio of deionized water to graphene oxide is 5500:1, ultrasonic, Stir until all dissolve and disperse to form a solution.

[0060] 2) Transfer the solution prepared in the preparation step 1) to a stainless steel autoclave for hydrothermal reaction. The hydrothermal temperature is 140°C, and the reaction time is 7h. After the reaction, use a centrifuge to collect the precipitate at 8000r / min;

[0061] 3) Dry the collected precipitate at a drying temperature of 55° C. and a drying time of 55 hours to completely evaporate the water to obtain a zinc oxide precursor.

[0062] 4) Put the above powder into a calcination furnace for heat treatment. The box-type silicon carbide rod-type muffle furnace heats up to 500°C at a rate of 2°C / min, and then keeps it for 3 hours. Finally, take out the ultra-thin porous oxide powder...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com