A preparation method of Gan-based LEDs with conductive DBR

A technology of porous conductive and transparent conductive layers, applied in circuits, electrical components, semiconductor devices, etc., can solve problems such as difficult process control, long growth time, DBR cracking, etc., and achieve improved luminous efficiency, simple preparation method, and reduced cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

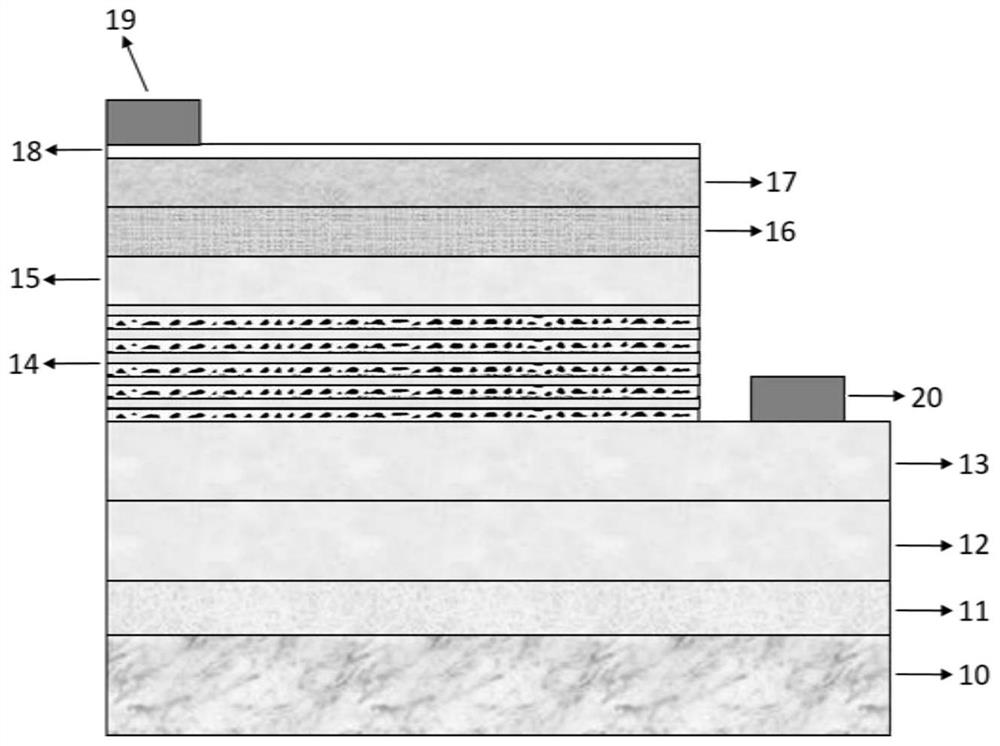

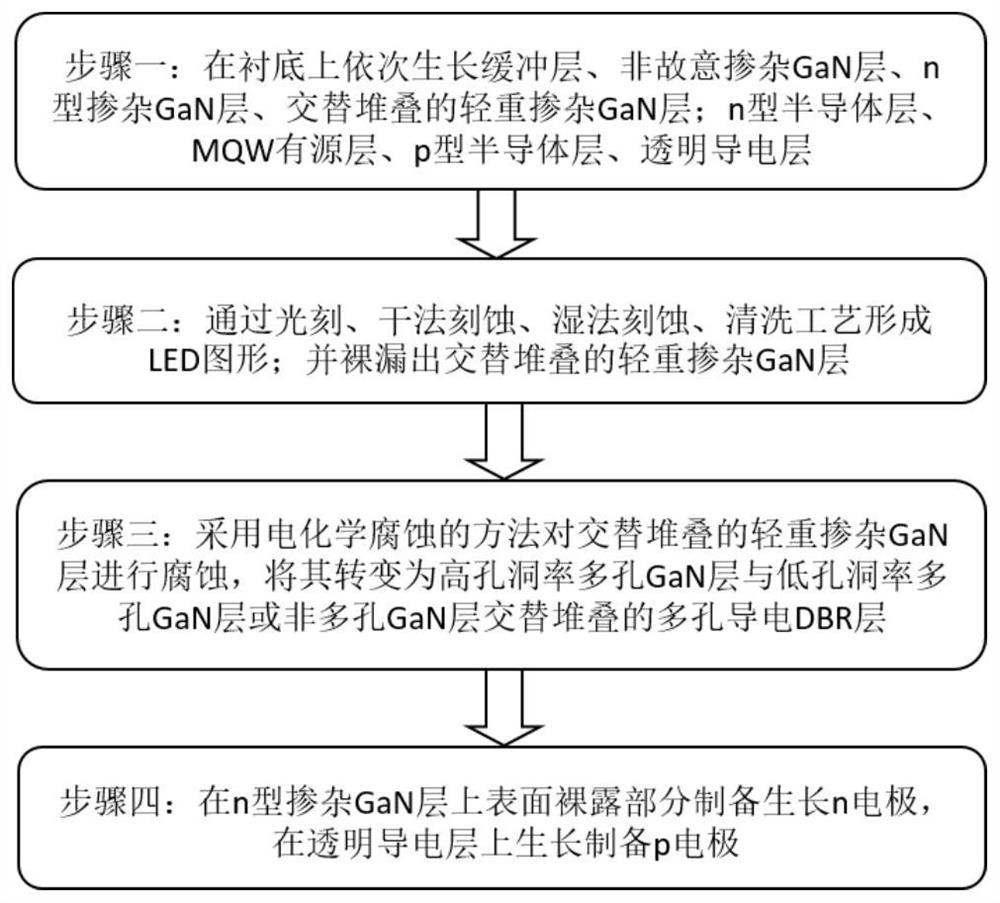

[0043] A GaN-based LED with a conductive DBR, such as figure 1 As shown, including a substrate 10, a buffer layer 11, an unintentionally doped GaN layer 12, and an n-type doped GaN layer 13 are sequentially grown on the upper surface of the substrate 10, and the upper surface of the n-type doped GaN layer 13 is partially exposed, and n A porous conductive DBR layer 14 is grown on the doped GaN layer 13, and an n-type semiconductor layer 15, an MQW active layer 16, a p-type semiconductor layer 17, and a transparent conductive layer 18 are sequentially grown on the upper surface of the porous conductive DBR layer 14;

[0044] An n-electrode 20 is provided on the exposed part of the upper surface of the n-type doped GaN layer 13, and a p-electrode 19 is provided on the transparent conductive layer 18;

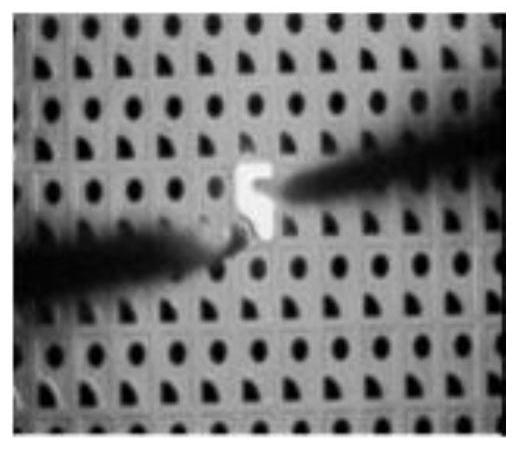

[0045] The porous conductive DBR layer 14 is an alternately stacked high-porosity porous GaN layer and a low-porosity porous GaN layer formed after the transparent conductive laye...

Embodiment 2

[0048] A GaN-based LED with a conductive DBR, the structure is as shown in Embodiment 1, the difference is that the porous conductive DBR layer 14 is a multi-period DBR structure formed by alternately stacking high-porosity porous GaN layers and low-porosity porous GaN layers , the period number is 15, and the pore diameter of the porous conductive DBR layer 14 is 1-300 nm.

Embodiment 3

[0050] A GaN-based LED with a conductive DBR, the structure is as shown in Embodiment 2, the difference is that the substrate 10 is sapphire, the material of the buffer layer 11 is AlN, and the dopant of the n-type doped GaN layer 13 is silicon , the transparent conductive layer 18 is ITO, and both the n electrode and the p electrode are Ti electrodes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com