A quantum dot light-emitting diode qled device and its manufacturing method and device

A technology of quantum dot luminescence and manufacturing method, which is applied in the manufacture of semiconductor/solid-state devices, electric solid-state devices, semiconductor devices, etc. It can solve problems affecting the performance of quantum dot light-emitting layers, improve interface defects, ensure luminous performance, and improve devices. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

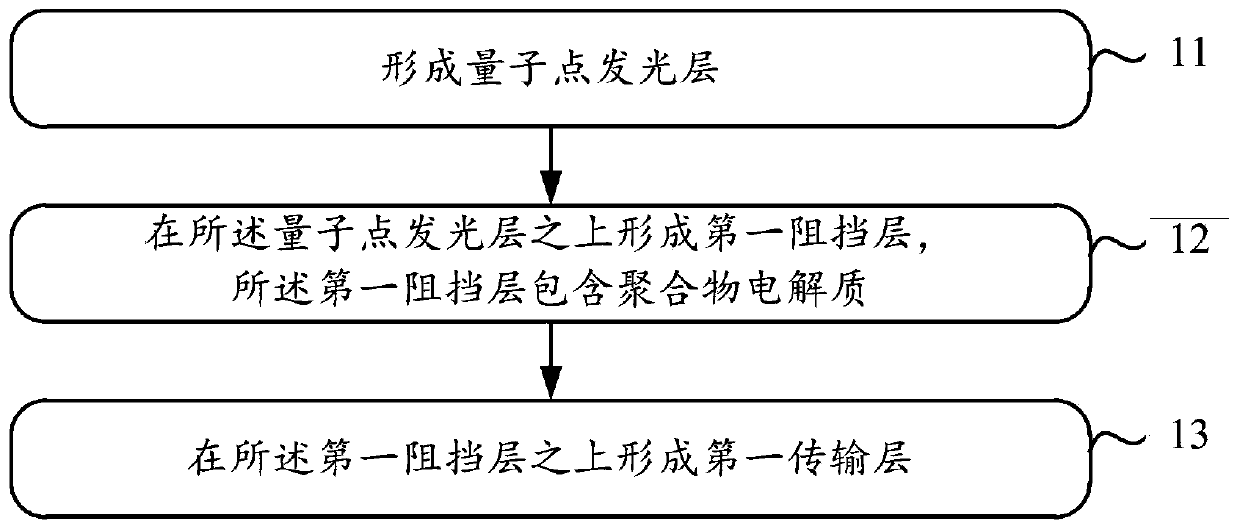

[0044] The embodiment of the present application provides a method for manufacturing a QLED device, such as figure 2 As shown, the method mainly includes the following steps:

[0045] Step 11: forming a quantum dot light-emitting layer.

[0046] In a specific production process, the quantum dot light-emitting layer can be prepared by a solution method. The quantum dot luminescent layer can be fabricated on a substrate, and before fabricating the quantum dot luminescent layer, the method can further include sequentially fabricating an anode, a hole transport layer, and the like on the substrate.

[0047] Step 12: forming a first barrier layer on the quantum dot light-emitting layer, the first barrier layer comprising a polymer electrolyte.

[0048] Wherein, the first barrier layer is used to prevent at least part of the nanoparticles in the first transport layer from leaking to the quantum dot light-emitting layer. A polymer electrolyte is an electrolyte material in the for...

Embodiment 2

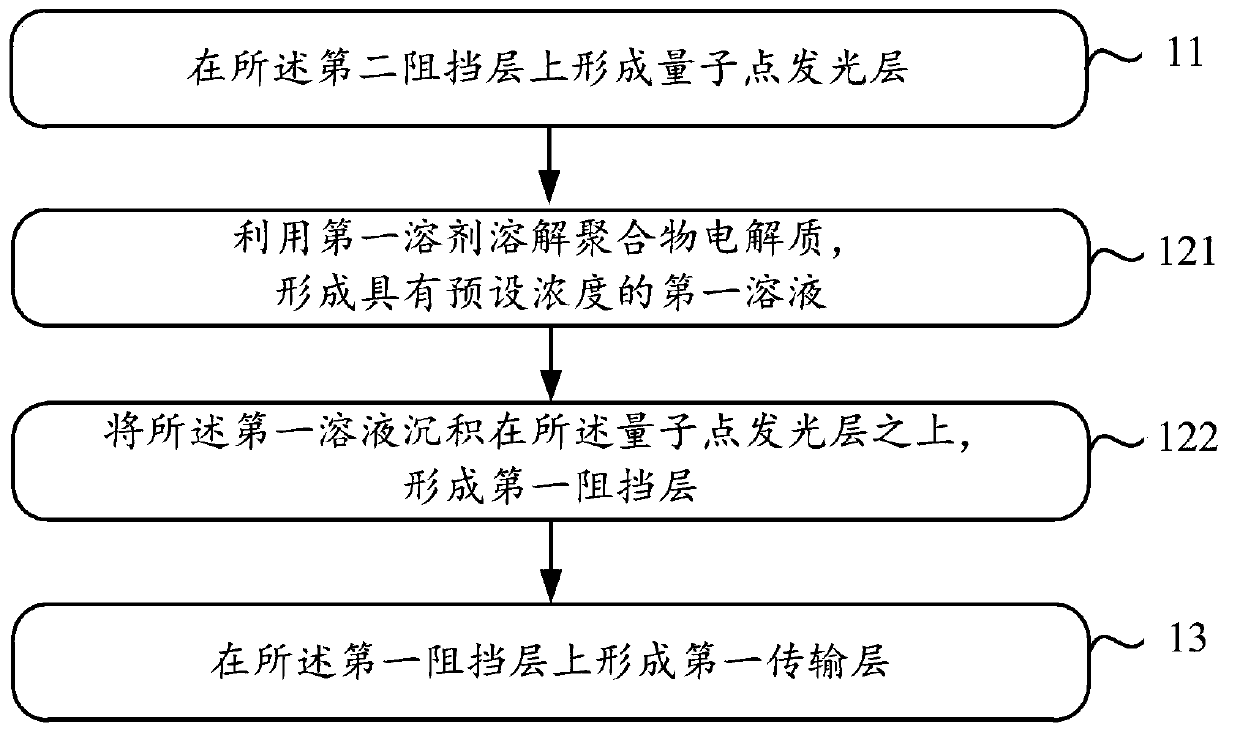

[0055] Based on the above-mentioned scheme, the manufacturing method of the QLED device provided by the embodiment of the present application, see image 3 shown, including:

[0056] Step 11: forming a quantum dot light-emitting layer.

[0057] Specifically, the method steps for forming the quantum dot light-emitting layer can be as shown in the above-mentioned embodiments, and will not be repeated here. The process of forming the first barrier layer in step 12 can be specifically implemented through the following steps 121 and 122 .

[0058] Step 121: Dissolving the polymer electrolyte with a first solvent to form a first solution with a preset concentration.

[0059] In this step, the first solvent used to dissolve the polymer electrolyte is determined; considering that the first barrier layer needs to be made on the quantum dot light-emitting layer, in order to avoid mutual solubility of solvents between adjacent film layers, it is necessary to When making the layer, the...

Embodiment 3

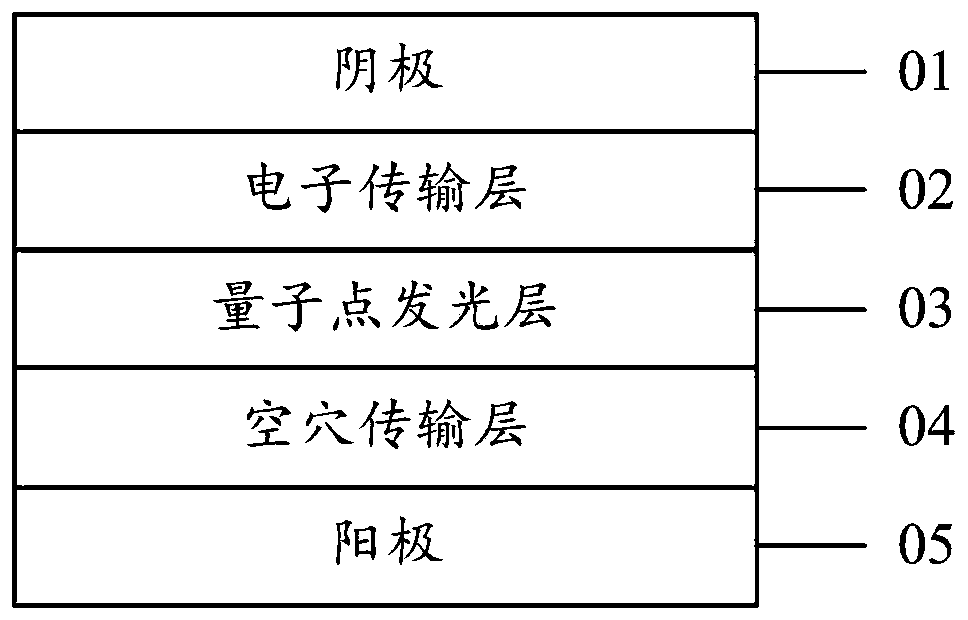

[0083] The film layer structure of the QLED device provided by the embodiment of the present application is as follows: Figure 6 As shown, it mainly includes: a quantum dot luminescent layer 61, a first transport layer 62 located on the quantum dot luminescent layer 61, and a second transport layer 62 located between the quantum dot luminescent layer 61 and the first transport layer 62 A barrier layer 63, the first barrier layer 63 includes a polymer electrolyte; wherein, the first barrier layer 63 is used to block at least part of the nanoparticles in the first transport layer 62 from leaking to the quantum dots to emit light Layer 61.

[0084] Considering that in this application, the first transport layer can be either an electron transport layer or a hole transport layer, then, when only the first barrier layer exists, the QLED device can include the following two structures:

[0085] Structure 1: The first transport layer is an electron transport layer.

[0086] like ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com