Organic chemical engineering finish distillation residue incineration treatment system

A disposal system and fine distillation technology, applied in combustion product treatment, incinerators, combustion methods, etc., can solve problems such as imperfect treatment, and achieve the effect of taking into account ecological and economic benefits, compact layout, and complete effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

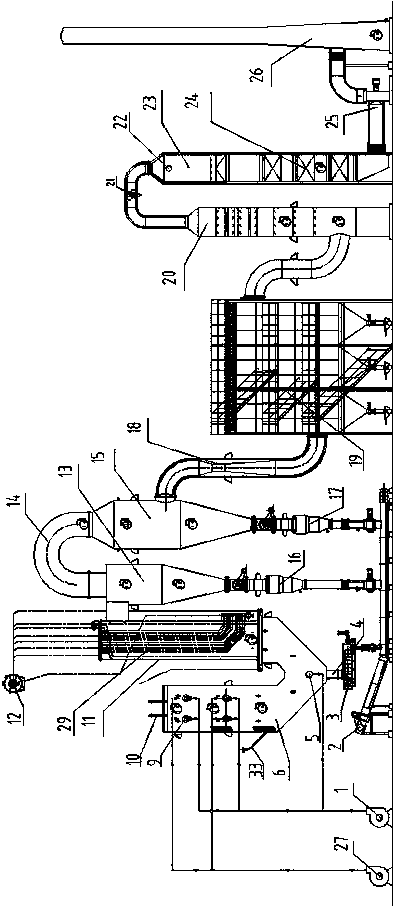

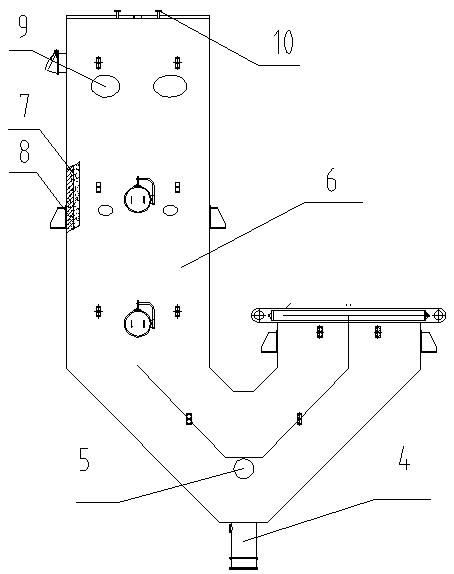

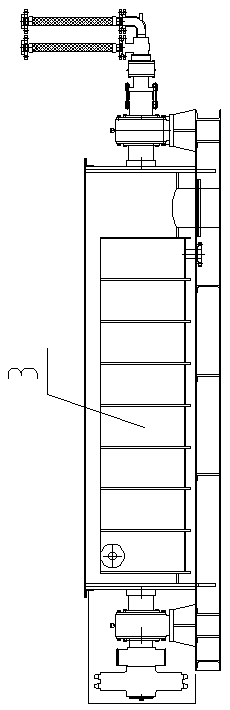

[0032] Embodiment 1: An organic chemical refining distillation residue incineration disposal system, the main equipment includes a combustion-supporting fan 1, a water-cooled scraper slag remover 2, a biaxial cooler 3, a residue incinerator 6, a waste heat boiler 11, a steam drum 12, and a cyclone Separator 13, water spray cooling tower 15, bag filter 19, deacidification tower 20, flue gas reheater 23, SCR denitrification device 24, induced draft fan 25, chimney 26. The inner wall of the residue incinerator 6 is coated with an acid-alkali-resistant, high-temperature-resistant chrome corundum refractory castable 7, and an insulating castable 8 is arranged between the inner wall of the residue incinerator 6 and the chrome corundum refractory castable 7. Solid waste feeder 33 is installed on the residue incinerator. The left end of the residue incinerator 6 is divided into three parts: the top, the upper part and the lower part. The top is provided with a waste liquid atomizing s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com