Method for preparing high-performance lead zirconate titanate piezoelectric film bottom electrode

A lead zirconate titanate piezoelectric and lead zirconate titanate technology is applied in the manufacture/assembly of piezoelectric/electrostrictive devices, etc., to improve the degree of preferred orientation and electrical properties, excellent dielectric properties, and reduce production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

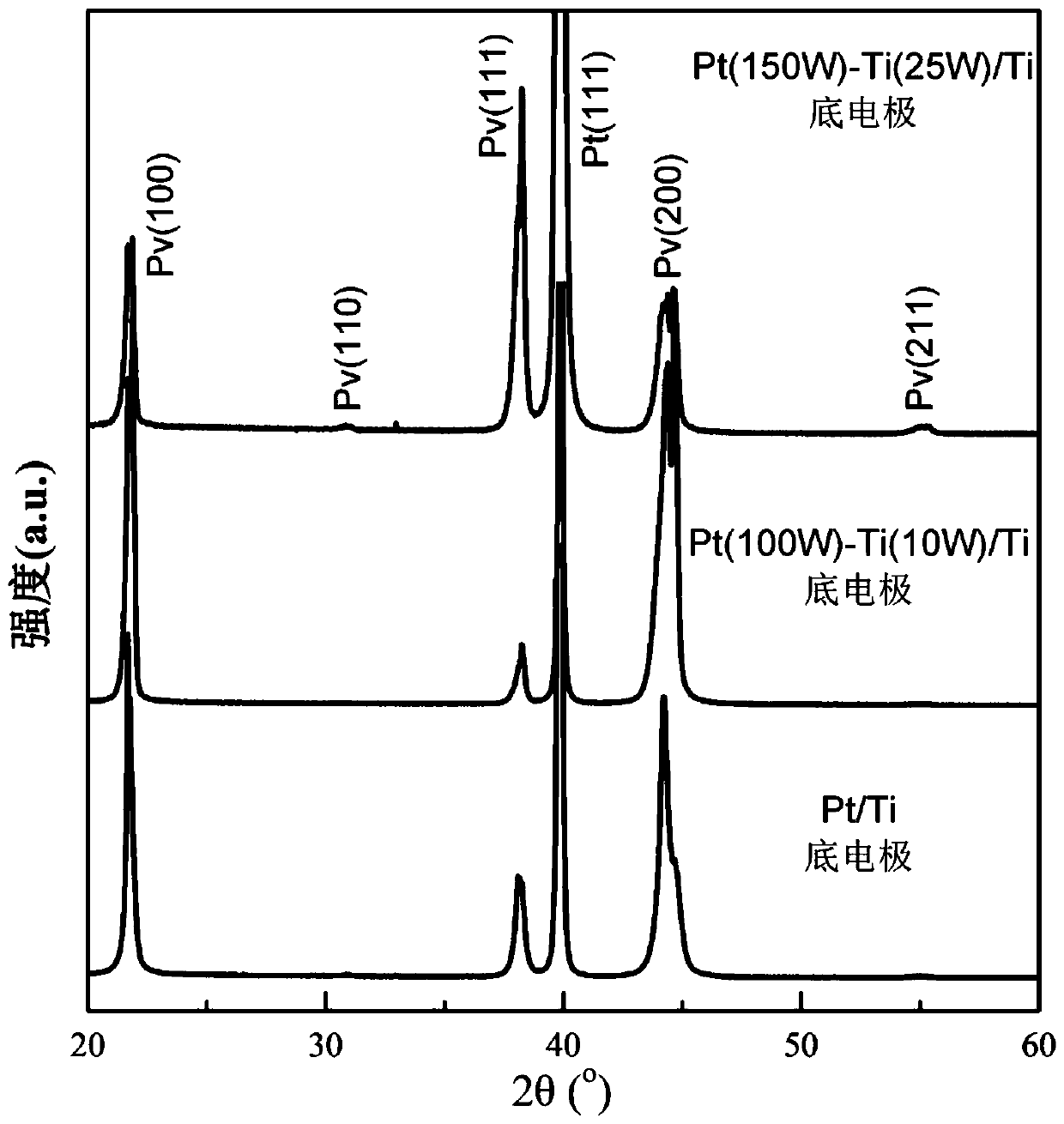

[0038] This example provides the Pt / Ti / SiO 2 The preparation method of the (100) preferred orientation lead zirconate titanate piezoelectric film deposited on the / Si bottom electrode, the steps are specifically:

[0039]S101, the preparation chemical formula is Pb(Zr y Ti 1-y )O 3 The lead zirconate titanate precursor solution

[0040] In order to compensate for the loss of lead in the post-annealing process, an excess of 20% of the lead element is considered in the batching. First measure 1.7mL acetylacetone solution, then dissolve 2.9mL tetrabutyl titanate in acetylacetone and raise the temperature to 50°C, keep it warm for 80 minutes; then add 4.02g zirconium nitrate, 10.53g lead acetate and 26mL ethylene glycol Methyl ether, stir evenly, heat up to 70°C, keep warm for 80 minutes; then add 1.8mL formamide, stir evenly and cool down to 50°C, keep warm for 80 minutes; finally add 12mL acetic acid solution and keep warm for 80 minutes, the pH value is 3.5 1. A lead zirco...

Embodiment 2

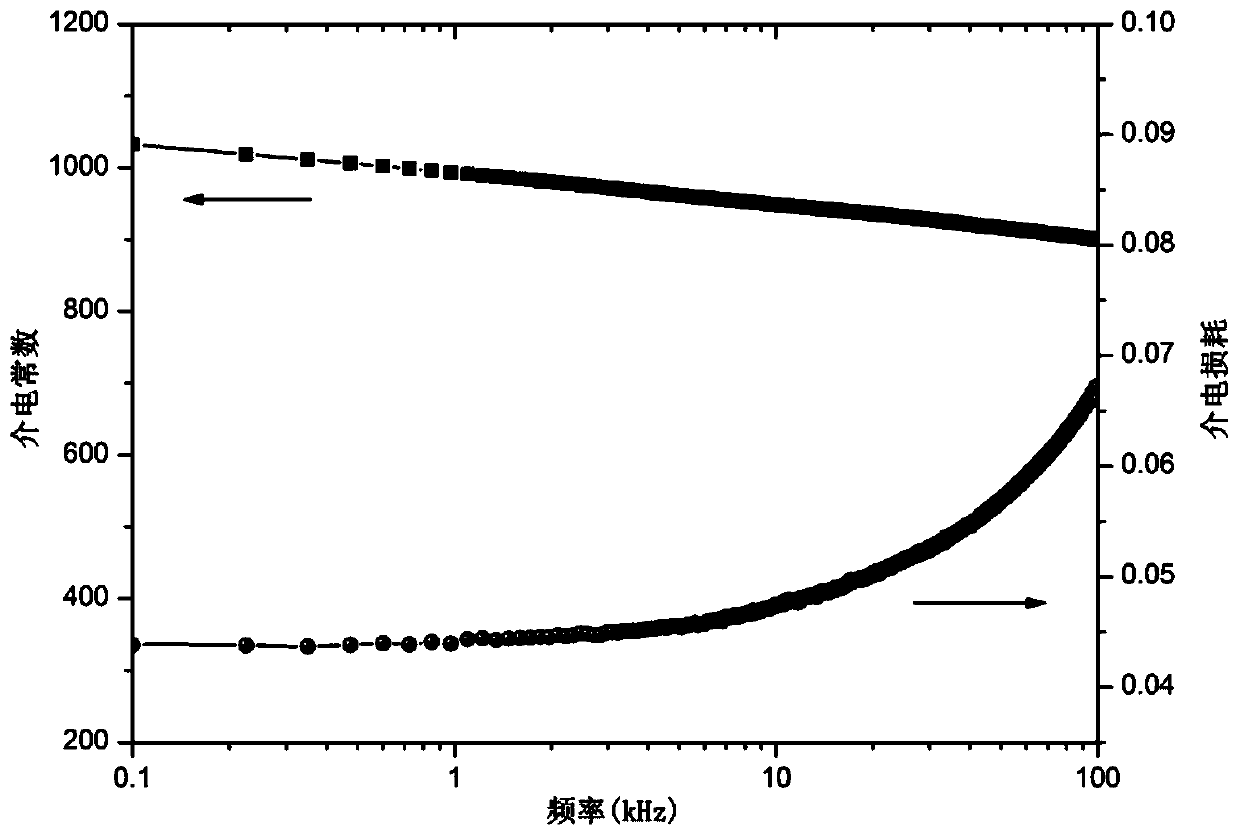

[0051] This embodiment provides Pt-Ti / Ti / SiO 2 The preparation method of the (100) preferred orientation lead zirconate titanate piezoelectric film deposited on the / Si bottom electrode, the steps are specifically:

[0052] S201, preparing Pt-Ti / Ti / SiO 2 / Si bottom electrode

[0053] Formation of 100nm thick SiO by dry oxidation on a two-inch Si wafer 2 layer, and then put the Si sheet on the sample stage of the magnetron sputtering instrument to deposit metal electrodes. Before deposition, the background vacuum of the sputtering apparatus was pumped to 3.0×10 -5 Pa, then fill in pure Ar gas and adjust the deposition pressure to 1Pa, turn on the DC power supply corresponding to the Ti target and set the sputtering power to 80W, open the sample baffle after glowing, and control the deposition time to 5min, first in SiO 2 A pure metal Ti layer with a thickness of 60nm was prepared on the / Si substrate. After the deposition of the pure Ti layer, close the sample baffle and a...

Embodiment 3

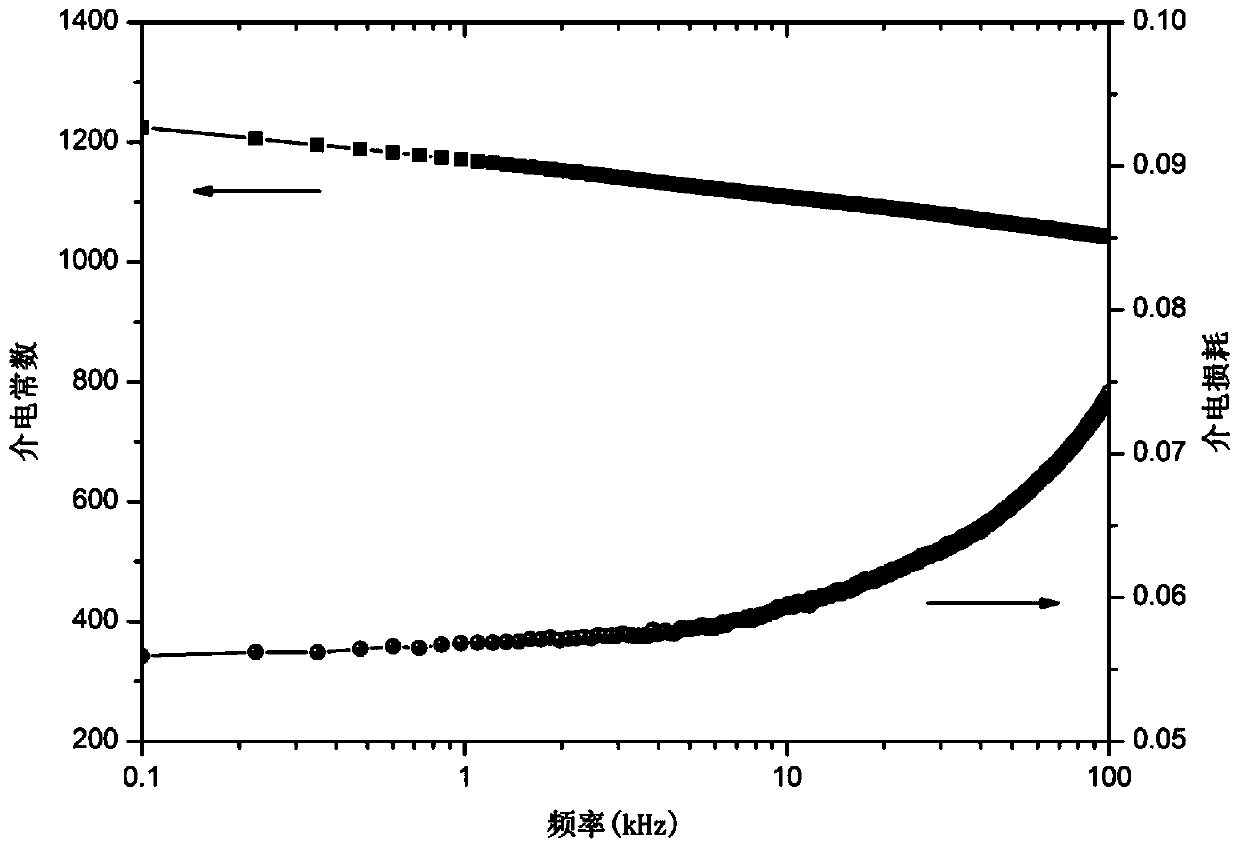

[0062] This embodiment provides Pt-Ti / Ti / SiO 2 The preparation method of the (100) preferred orientation lead zirconate titanate piezoelectric film deposited on the / Si bottom electrode, the steps are specifically:

[0063] S301, preparing Pt-Ti / Ti / SiO 2 / Si bottom electrode

[0064] Formation of 100nm thick SiO by dry oxidation on a two-inch Si wafer 2 layer, and then put the Si sheet on the sample stage of the magnetron sputtering instrument to deposit metal electrodes. Before deposition, the background vacuum of the sputtering apparatus was pumped to 5.0×10 -5 Pa, then fill in pure Ar gas and adjust the deposition pressure to 1.2Pa, turn on the DC power supply corresponding to the Ti target and set the sputtering power to 50W, open the sample baffle after glowing, control the deposition time to 8min, first in SiO 2 A pure metal Ti layer with a thickness of 50nm was prepared on the / Si substrate. After the deposition of the pure Ti layer, close the sample baffle and adj...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| relative permittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com