Method for preparing CL-20 through two-step method

A CL-20, one-step technology, applied in the field of two-step preparation of CL-20, can solve the problems of complex reaction route, poor atom economy, long cycle, etc., and achieve the effect of reducing cost, simplifying preparation process and shortening synthesis cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A two-step method for preparing CL-20, comprising the following two steps:

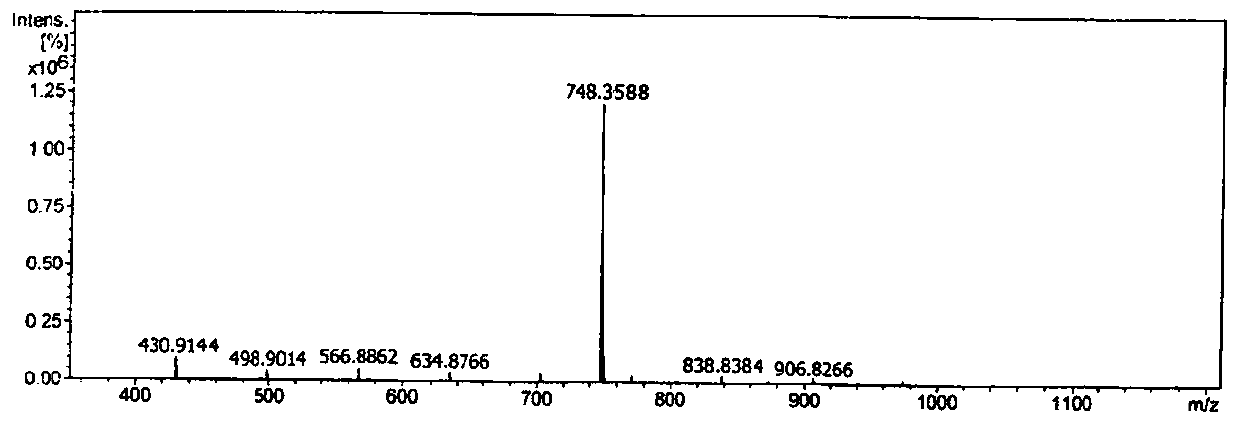

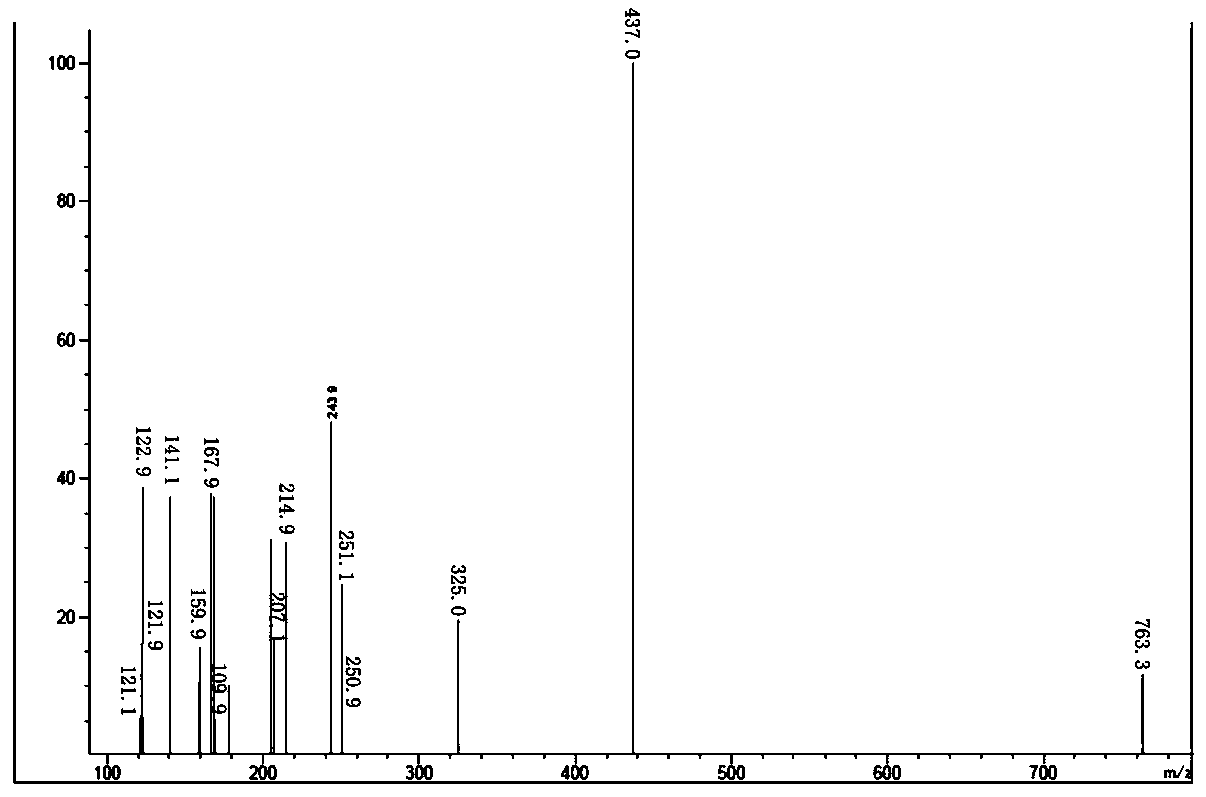

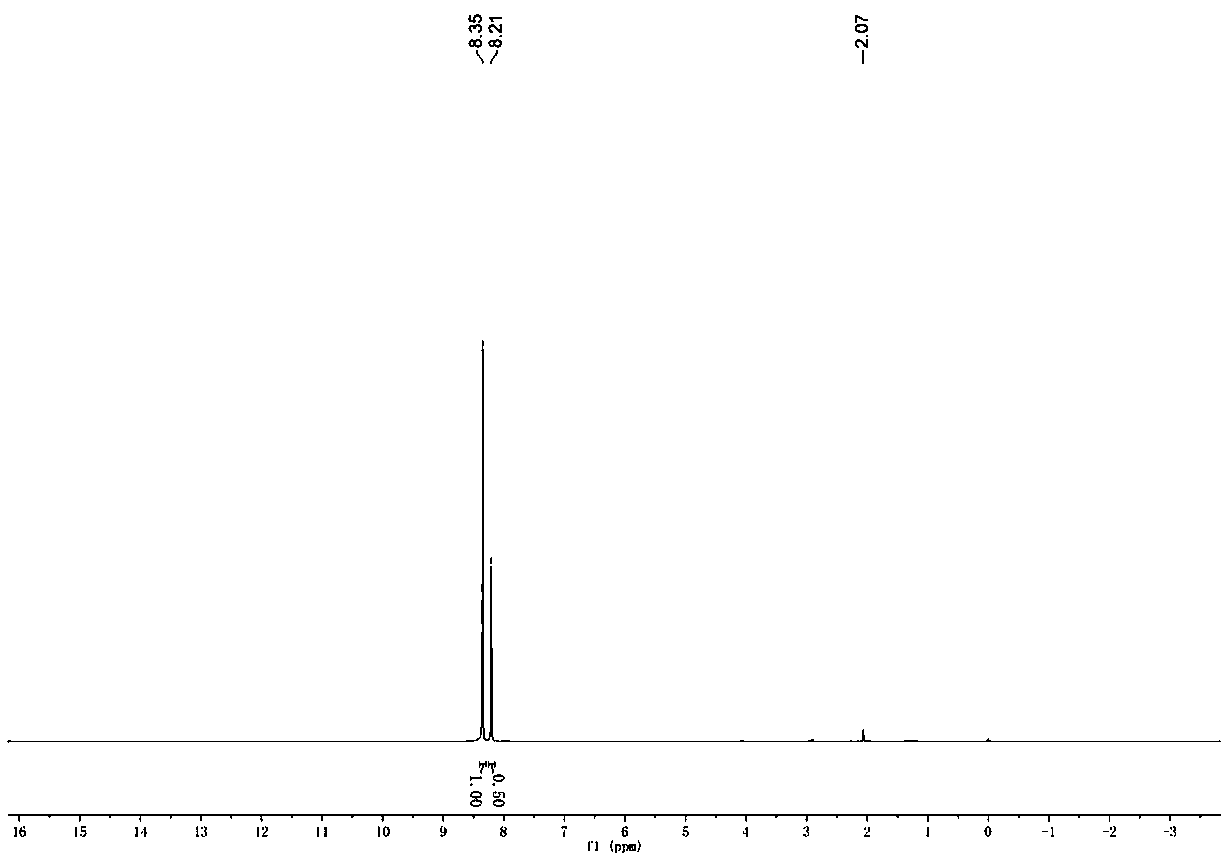

[0047] 1) Dissolve 5.68g of ammonium sulfamate (50mmol) in 5.7mL of deionized water, add the solution to a 100mL four-neck flask, then add 2.9mL of 40% glyoxal (25mmol) aqueous solution at room temperature, and stir under 20 React at ℃ for 24 hours, filter, and dry to obtain 0.93 g of white powder HSIW; a sufficient amount of HSIW can be obtained by repeating the above steps.

[0048] 2) Dissolve 0.5g of ammonium nitrate in 5.0g of fuming nitric acid to prepare an ammonium nitrate-nitric acid solution; add 10.0g of acetic anhydride to a 100mL four-necked bottle and lower the temperature to below 10°C, and prepare the prepared ammonium nitrate-nitric acid solution Slowly add the solution into acetic anhydride, then add 3.0g HSIW in batches and at the same time add 10.0g acetic acid to the system to obtain a nitration solution; react the nitration solution at 0°C for 8 hours, then pour it into 10...

Embodiment 2

[0050] A two-step method for preparing CL-20, comprising the following two steps:

[0051] 1) Dissolve 7.10 g of ammonium sulfamate (62.5 mmol) in 5.7 mL of deionized water, add the solution to a 100 mL four-neck flask, then add 2.9 mL of 40% glyoxal (25 mmol) aqueous solution at room temperature, and place under stirring React at 10°C for 48 hours, filter, and dry to obtain 1.07 g of white powder, which is designated as HSIW; a sufficient amount of HSIW can be prepared by repeating the above steps.

[0052] 2) Dissolve 0.5g of ammonium nitrate in 5.0g of fuming nitric acid to prepare an ammonium nitrate-nitric acid solution; add 10.0g of acetic anhydride to a 100mL four-necked bottle and lower the temperature to below 10°C, and prepare the ammonium nitrate- Slowly add nitric acid solution into acetic anhydride, then add 3.0g HSIW in batches and at the same time add 10.0g acetic acid to the system to obtain a nitration solution; react the nitration solution at 30°C for 4h, the...

Embodiment 3

[0054] A two-step method for preparing CL-20, comprising the following two steps:

[0055] 1) Dissolve 8.52g of ammonium sulfamate (75mmol) in 5.7mL of deionized water, add the solution to a 100mL four-neck flask, then add 2.9mL of 40% glyoxal (25mmol) aqueous solution at room temperature, and place under stirring in - React at 20°C for 24 hours, filter, and dry to obtain 1.03 g of white powder, which is designated as HSIW; a sufficient amount of HSIW can be prepared by repeating the above steps.

[0056] 2) Dissolve 0.5g of ammonium nitrate in 5.0g of fuming nitric acid to prepare an ammonium nitrate-nitric acid solution; add 10.0g of acetic anhydride to a 100mL four-necked bottle and lower the temperature to below 10°C, and prepare the ammonium nitrate- Slowly add nitric acid solution into acetic anhydride, then add 3.0g HSIW in batches and at the same time add 15.0g acetic acid to the system to obtain a nitration solution; react the nitration solution at 30°C for 4h, then p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com