150 DEG C irradiation cross-linked low-smoke halogen-free flame-retardant elastomer cable material for new energy automobile and preparation method of cable material

A new energy vehicle, elastomer technology, applied in circuits, insulators, electrical components, etc., to achieve excellent electrical properties, excellent tensile properties and tear resistance, and good apparent quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

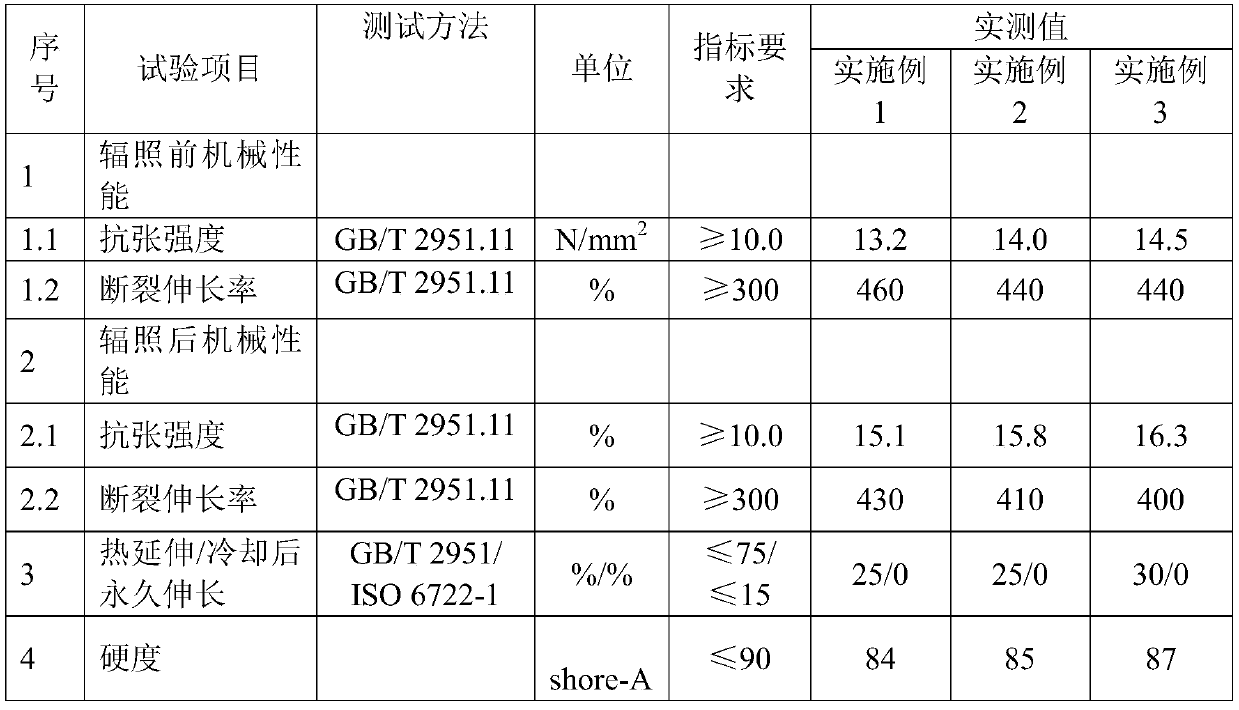

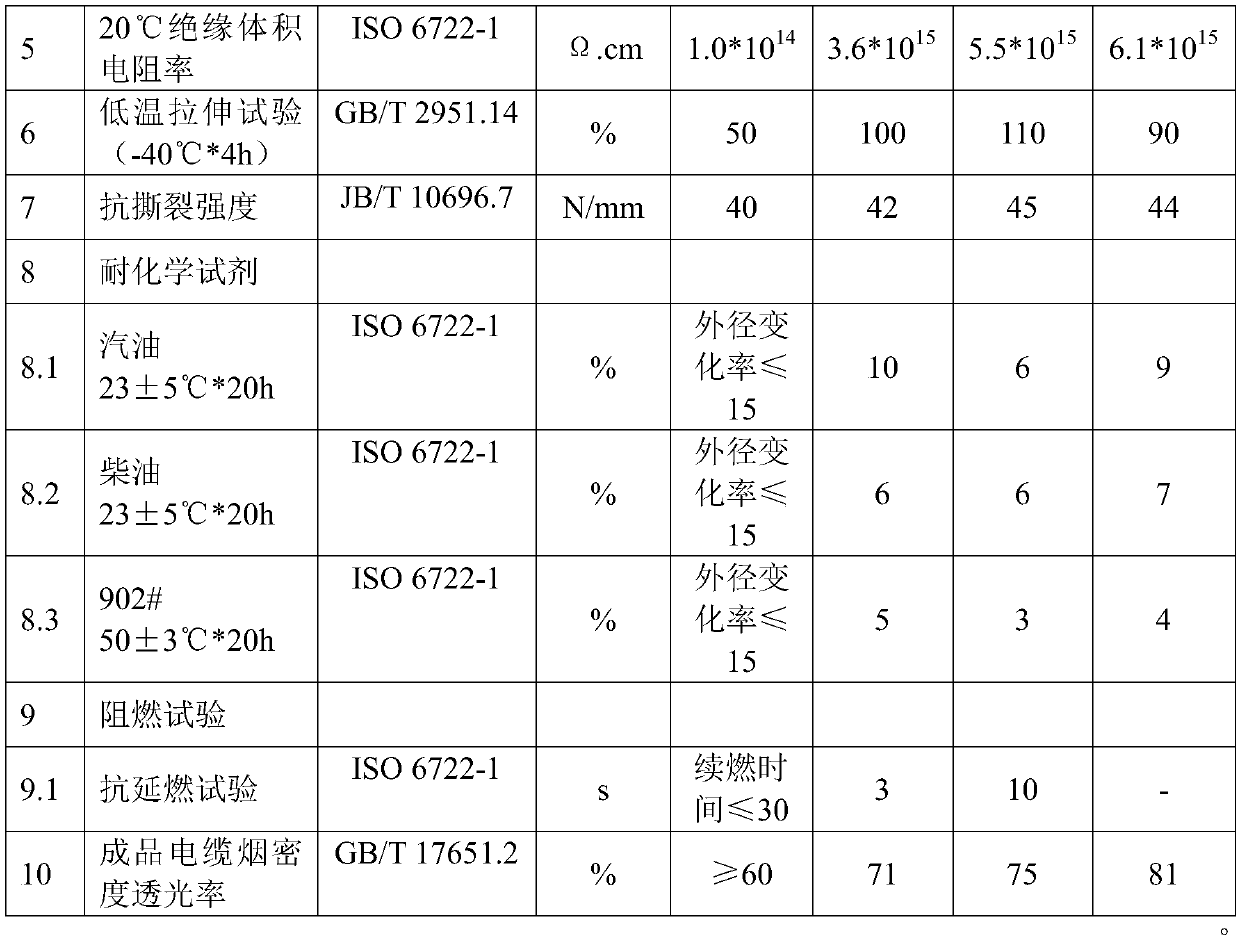

Examples

Embodiment 1

[0023] Raw material components: ethylene-butyl acrylate copolymer (Spain Repsol EBA 1770, pellets) 50 parts, hydrogenated styrene-butadiene block copolymer (SEBS American Kraton G7705-1001-01, pellets) 15 parts , ethylene-octene copolymer (US DOW 7467, pellets) 25 parts, compatibilizer (SEBS-g-MAH, domestic M5600, pellets)) 10 parts, color masterbatch (Shanghai Wujiang orange masterbatch OR-3033 , pellets) 2.5 parts, hydroxide flame retardant (modified magnesium hydroxide ZH-E5, powder) 100 parts, phosphorus nitrogen flame retardant (PPAP, powder) 30 parts, lubricant (stearic acid Zinc, powder) 5 parts, coupling agent (KH-550, liquid) 1 part, antioxidant (antioxidant 445, antioxidant 412S, antioxidant 1010 and antioxidant 168, the mass ratio is 1:2 : 1:1 mixture, powder) 2.5 parts, cross-linking sensitizer (triallyl isocyanurate, powder) 1.5 parts, anti-copper agent (N, N ` - 0.3 parts of bis[β(3,5-di-tert-butyl-4-hydroxyphenyl)propionyl]hydrazine, powder), UV absorber (the m...

Embodiment 2

[0028] Raw material components: 50 parts of ethylene-butyl acrylate copolymer (German Lucobit 1440H, pellets), 20 parts of hydrogenated styrene-butadiene block copolymer (SEBS Kuraray 4044, pellets), ethylene-octene Copolymer (U.S. DOW POE8401, pellets) 15 parts, compatibilizer (SEBS-g-MAH (American Kraton F, FG1901, pellets) and EBA-g-MAH (Lucofin 1492HG, Shanghai Shouli Chemical Co., Ltd.) Mixture with a mass ratio of 1:2, pellets) 15 parts, color masterbatch (Shanghai Wujiang orange masterbatch OR-3033, pellets) 3 parts, hydroxide flame retardant (aluminum hydroxide flame retardant Yabao 104LEO , powder) 110 parts, phosphorus nitrogen flame retardant (PPAP, powder) 25 parts, lubricant (polyethylene wax W100, mixed with powder) 5 parts, coupling agent (A-172, liquid) 1 part , antioxidant (antioxidant 445, antioxidant 412S, antioxidant 1010 and antioxidant 168 mass ratio is the mixture of 1:2:1:1, powder) 2.5 parts, cross-linking sensitizer (three Allyl isocyanurate, liquid)...

Embodiment 3

[0034] Raw material components: 45 parts of ethylene-butyl acrylate copolymer (Repsol EBA 1715 from Spain, pellets), 20 parts of hydrogenated styrene-butadiene block copolymer (SEBS Taiwan Rubber 6150, China, pellets), ethylene- Octene copolymer (US DOWPOE8130, pellets) 20 parts, compatibilizer (SEBS-g-MAH (US Kraton F, FG1901, pellets), POE-g-MAH (US Dow GR208, pellets) and EBA-g-MAH (Lucofin 1492HG, Shanghai Shouli Chemical Co., Ltd., a mixture of pellets with a mass ratio of 1:1:2) 15 parts, color masterbatch (Shanghai Wujiang orange masterbatch OR-3033, pellets) 3 parts, hydroxide flame retardant (a mixture of modified magnesium hydroxide ZH-E5 and aluminum hydroxide flame retardant Yabao 104LEO with a mass ratio of 1:1, powder) 110 parts, phosphorus nitrogen flame retardant (PPAP , powder) 20 parts, lubricants (silicone masterbatch, pellets) 3 parts, coupling agent (A-172, liquid) 1.5 parts, antioxidants (antioxidant 445, antioxidant 412S, antioxidant A mixture of 1:2:1:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com