Novel fermentation device and application thereof for immobilized yeast fermentation preparation of ethyl alcohol

A fermentation device and immobilized carrier technology, applied in the direction of supporting/immobilizing microorganisms, fermentation, biochemical cleaning devices, etc., can solve problems such as poor results, and achieve simple production, reduce the probability of bacterial contamination, and complete discharge Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

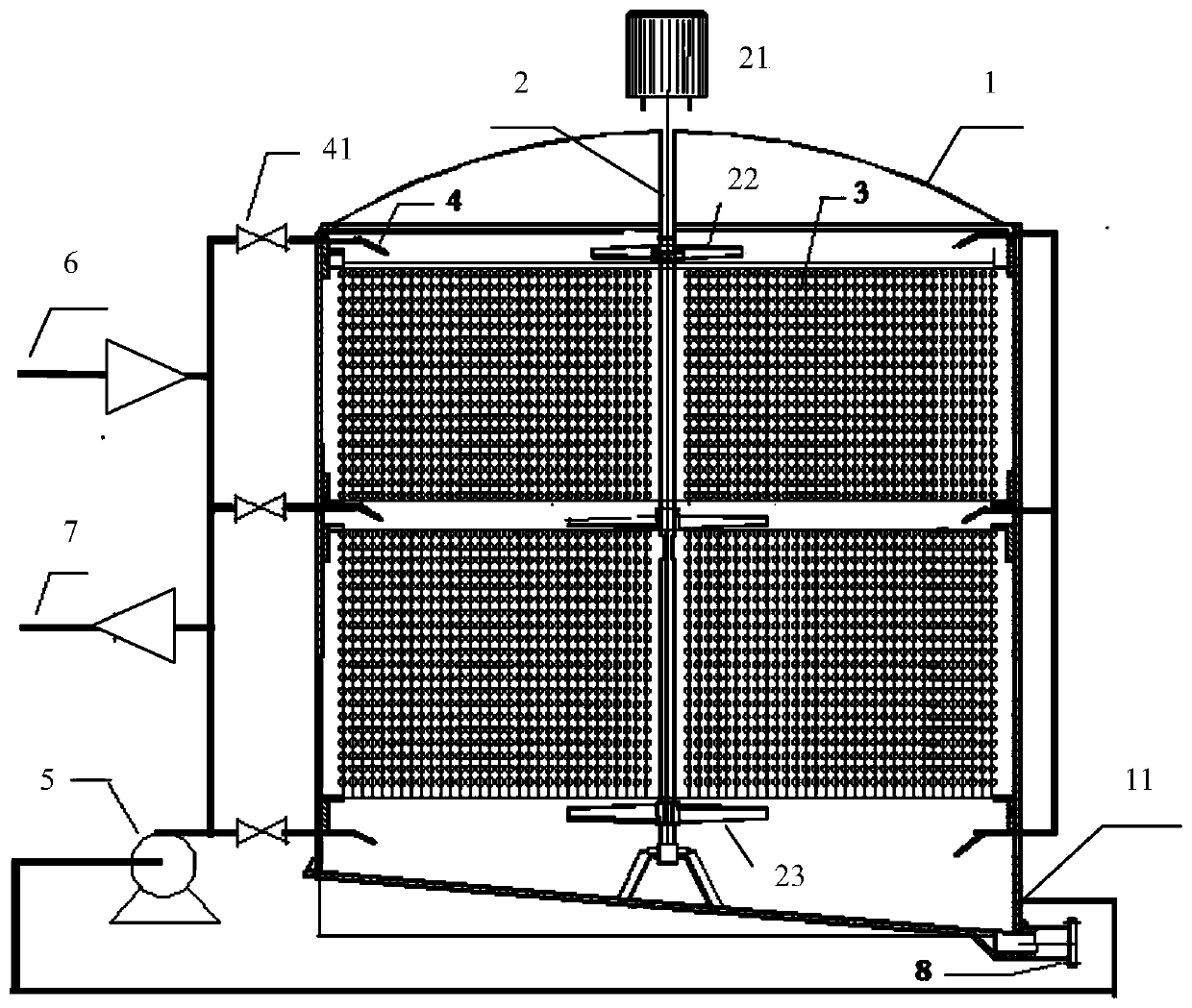

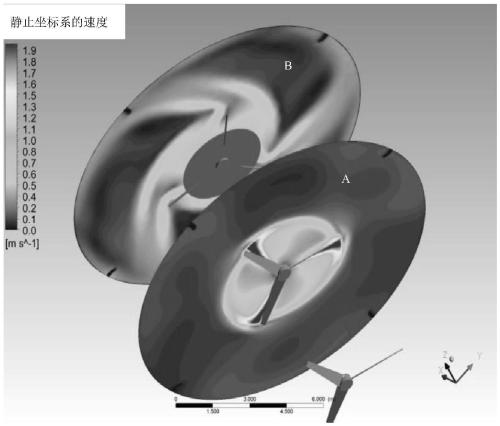

[0042] Simulation of fermenter structure and mass transfer without circulation:

[0043] The 2,000-ton fermenter with a height-to-diameter ratio of 1.2 is divided into two layers. The immobilized balls connected in series are fixed at both ends of the upper and lower grids of each layer. The vertical distance is 4 cm, and the horizontal distance is 5 cm. The actual loading capacity is about 10,500. Bottom, middle layer propelling type blade 23 diameter 5.33m, and horizontal direction included angle 30 ° big head width 43cm, small head width 10cm, 3 blades. Top flat paddle, rotation diameter 5m, disk diameter 3.5m, blade length 1.5m, width 0.1m, perpendicular to the horizontal direction, 3 blades. Under the condition of rotating speed 12r / min, the mass transfer condition is as follows Figure 2a and Figure 2b As shown, the average flow velocity of the upper layer (A) is 0.16m / s, the average flow velocity of the lower layer (B) is 0.14m / s, and the overall average flow velocity ...

Embodiment 2

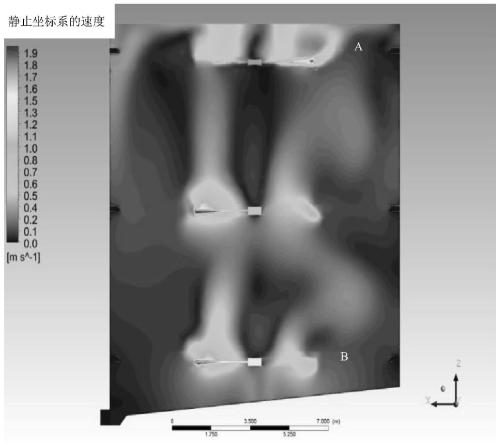

[0044] Embodiment 2 fermenter structure and mass transfer simulation with circulation

[0045] The circulating feed protrudes from the tank wall, with a design nozzle (such as Figure 3a Shown), other modes are with embodiment 1. Under the condition of rotating speed 12r / min, the mass transfer condition is as follows Figure 3b and 3c shown. The average flow velocity of the upper layer (A) is 0.17m / s, the average flow velocity of the lower layer (B) is 0.16m / s, and the overall average flow velocity is 0.165m / s, with better mass transfer effect.

Embodiment 3

[0046] Embodiment 3 is fermentation raw material with cassava liquefaction mash culture medium

[0047] The immobilized carrier is filled in the reactor in embodiment 2, with a circulation capacity of 900m 3 / h fix the seed solution for 48h (the seed medium is cassava mash, as described later). Until the bacterial cell adsorption concentration is 250 million / ml. Then prepare cassava liquefied mash: the ratio of solid to liquid is 1:2.3, add liquefying enzyme (16U / g cassava dry weight) to liquefy at 90°C for 1.5 hours, and discharge the immobilized seed waste liquid after cooling. Then add cassava liquefied mash (initial total sugar 226.0g / L, and add glucoamylase (180U / g cassava dry weight), liquid content 85%, carry out circular fermentation, wherein the temperature is 33 ° C, the pH of the fermentation liquid is 4.3, Velocity 900m 3 / h, the stirring speed is 12r / min, after the fermentation is finished, the fermentation liquid is drained, and the total residue of the feed l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com