Preparation method and application of chitosan/tap water plant aluminum sludge composite aerogel adsorption material

A composite airgel, waterworks technology, applied in the direction of water/sludge/sewage treatment, water pollutants, water/sewage treatment, etc., to achieve the effect of simple preparation method, large specific surface area and high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

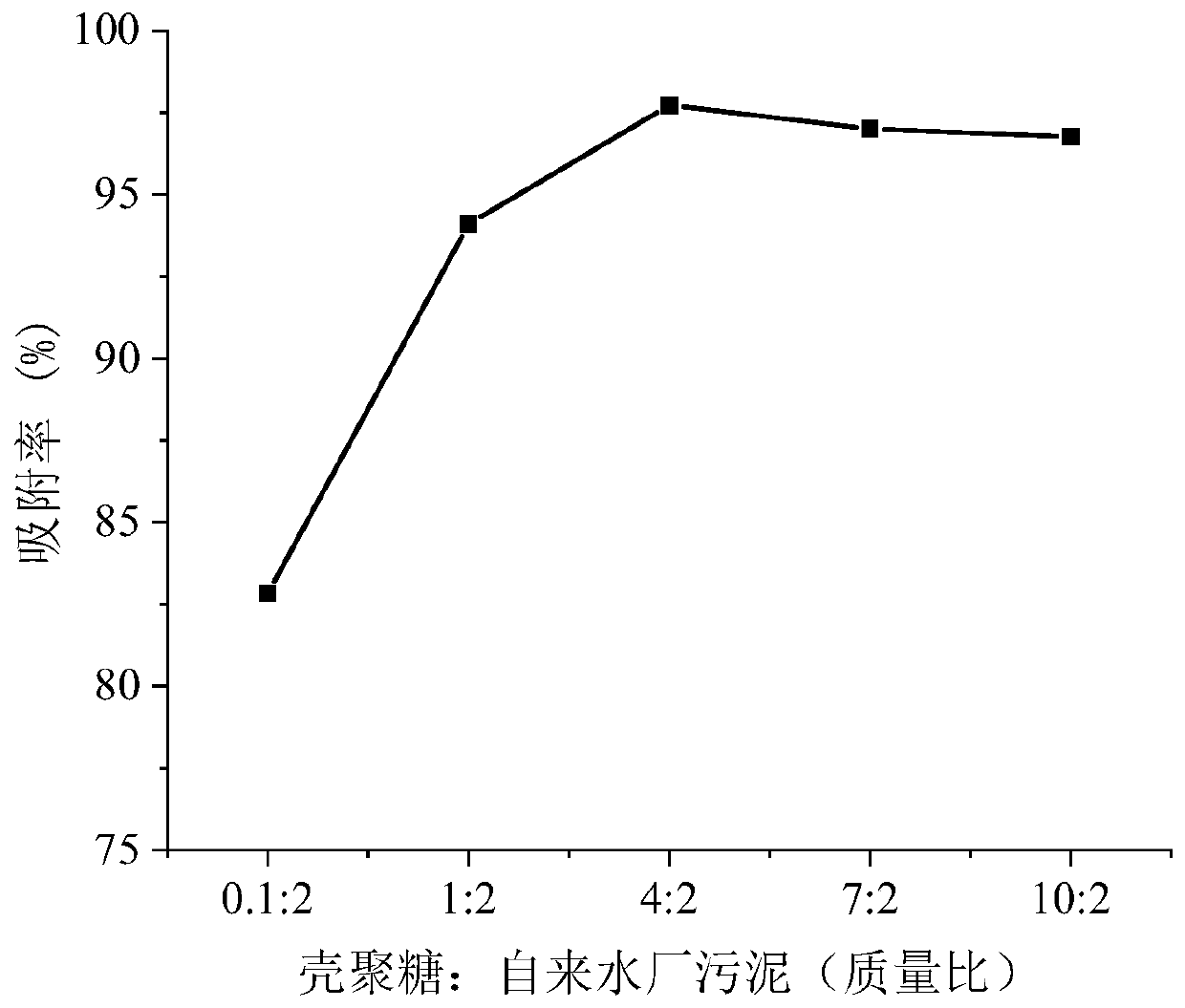

[0034] Preparation of chitosan / waterworks aluminum sludge composite airgel adsorbent materials with different mass ratios of chitosan and sludge:

[0035] (1) dissolving chitosan in a glacial acetic acid solution with a volume fraction of 1% to obtain a chitosan solution with a mass fraction of 0.1 to 10%;

[0036] (2) Get the dried aluminum sludge from the waterworks, add 10% blowing agent to it, and obtain the sludge slurry with the same mass fraction;

[0037] (3) Chitosan solution and mud are mixed and stirred evenly, and cryogenically frozen to make the material dense and uniform;

[0038] (4) Thaw with ethanol to separate out internal organic matter and moisture;

[0039] (5) Put the thawed composite airgel material into a pH 4-6 dilute hydrochloric acid solution, so that the foaming agent in the material reacts with the acid to generate gas, which escapes to form a composite adsorption material with a large number of pores;

[0040] (6) Appropriately shred the composi...

Embodiment 2

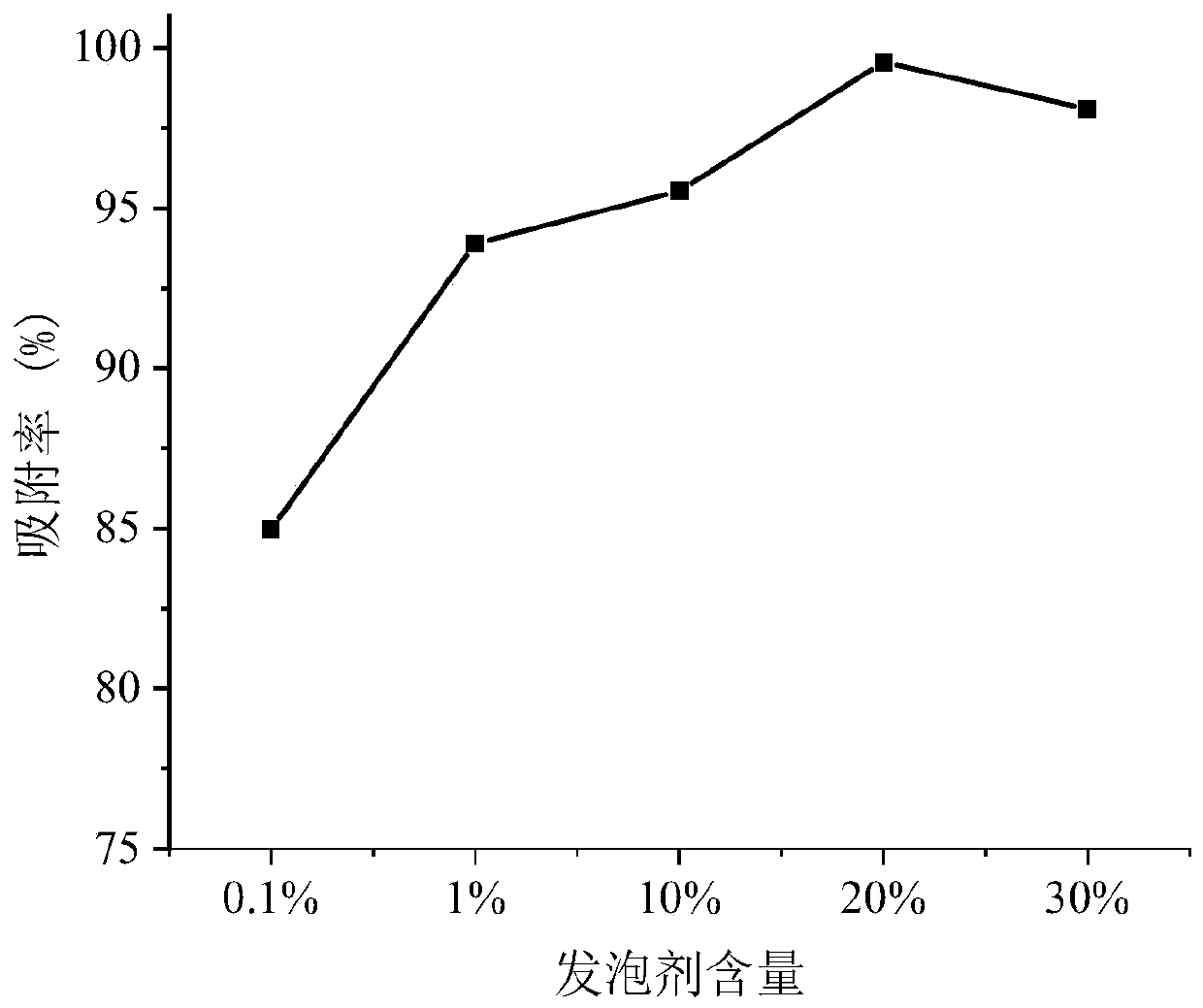

[0055] Preparation of chitosan / waterworks aluminum sludge composite airgel materials with different foaming dosages:

[0056] (1) dissolving chitosan in the glacial acetic acid that volume fraction is 1% obtains the chitosan solution of mass fraction 4%;

[0057] (2) Take an appropriate amount of dried aluminum sludge from a waterworks, and add 0.1 to 30% foaming agent therein to obtain sludge sludge with different foaming doses;

[0058] (3) Chitosan solution is mixed and stirred evenly with mud, and now chitosan mass fraction is 4%, and sludge mass fraction is 2%, namely chitosan is 4:2 than waterworks aluminum sludge mass ratio; Low-temperature freezing makes the material dense and uniform;

[0059](4) Thaw with ethanol to precipitate internal organic matter and moisture, and then soak in absolute ethanol for 1 to 3 hours;

[0060] (5) Put the thawed composite airgel material into a dilute hydrochloric acid solution with a pH of 4 to 6, so that the foaming agent in the ma...

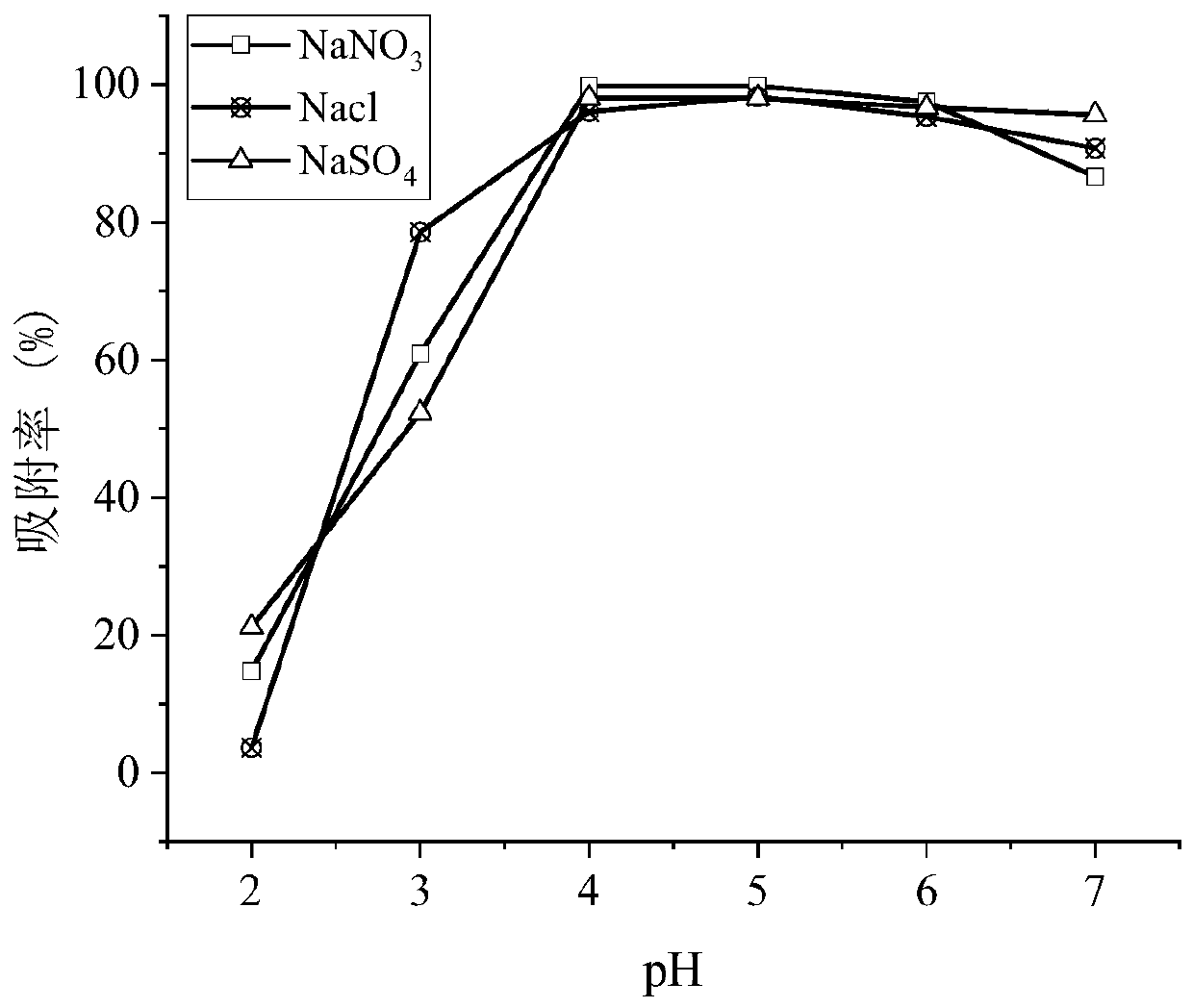

Embodiment 3

[0070] Prepare a sufficient amount of chitosan and sludge mass ratio of 4%: 2%, foaming dosage of 20% chitosan / waterworks aluminum sludge composite airgel adsorbent material, the specific implementation steps are as follows:

[0071] (1) Chitosan is dissolved in 1 to 3% glacial acetic acid to obtain a chitosan solution with a mass fraction of 4%;

[0072] (2) Take and dry the aluminum sludge of the waterworks, add 20% blowing agent to it, obtain the sludge slurry of the same mass fraction;

[0073] (3) Chitosan solution and mud are mixed and stirred evenly, and cryogenically frozen to make the material dense and uniform;

[0074] (4) Thaw with ethanol, separate out the internal organic matter and moisture, and then soak for 1 hour;

[0075] (5) Put the thawed composite airgel material into a dilute hydrochloric acid solution with a pH of 4 to 6, so that the foaming agent in the material reacts with the acid to generate gas, which escapes to form a composite adsorption materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com