Graphene dispersion liquid and production method and application thereof

A graphene dispersion, graphene technology, applied in graphene, chemical instruments and methods, inorganic chemistry and other directions, can solve problems such as no operation method, unfavorable performance stability of graphene, and achieve good electrical conductivity and preparation. The method is simple and the effect of ensuring the integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

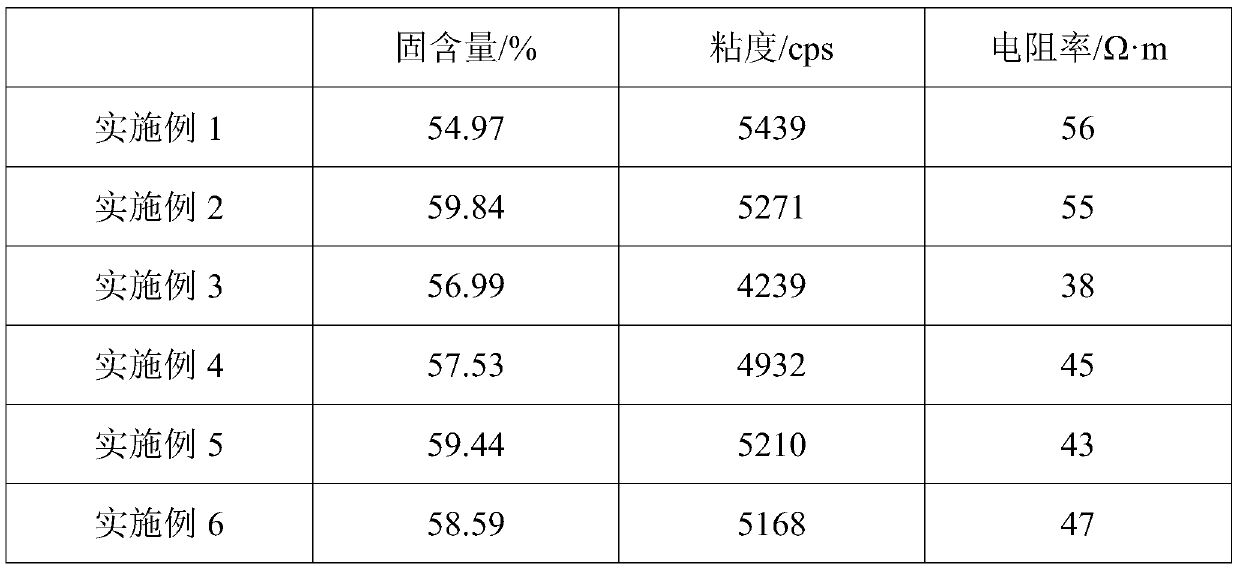

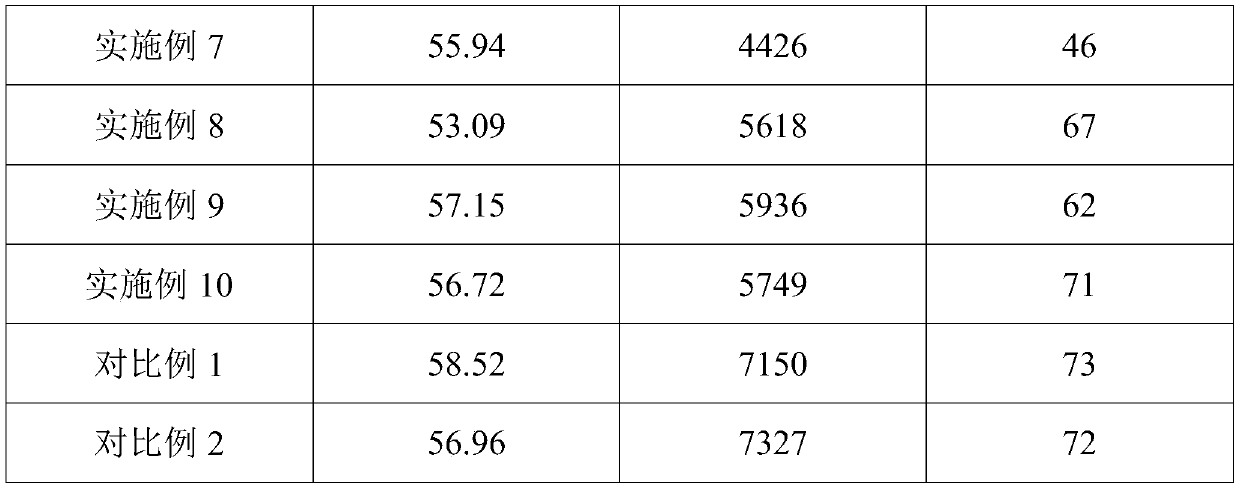

Examples

Embodiment 1

[0053] The present embodiment provides a kind of preparation method of graphene dispersion liquid, described method comprises the steps:

[0054] (1) Mix graphene and hexadecyltrimethylammonium bromide at a mass ratio of 1:30 at 20°C to obtain surface-functionalized graphene;

[0055] (2) Mix deionized water and step (1) gained surface functionalized graphene by liquid-solid ratio 1000:1, ultrasonic 60min for the first time under 310W power, one-time adding by mass ratio 3 when ultrasonic for the first time: The surfactant that the sodium glycocholate of 1:6, sodium cocoate and coconut oil diethanolamide form, the mass ratio of the addition of surfactant and the graphene of step (1) gained surface functionalization is 4: 100, stand still for 30 minutes, and then ultrasonicate for 60 minutes for the second time under 700W power to obtain a well-mixed mixture;

[0056] (3) Centrifuge the mixed solution obtained in step (2) for 25 minutes at a rotating speed of 110r / min, collect...

Embodiment 2

[0059] The present embodiment provides a kind of preparation method of graphene dispersion liquid, described method comprises the steps:

[0060] (1) Mix graphene and hexadecyltrimethylammonium bromide at a mass ratio of 1:30 at 20°C under anaerobic conditions to obtain surface-functionalized graphene;

[0061] (2) Mix deionized water and step (1) gained surface functionalized graphene by liquid-solid ratio 1000:1, ultrasonic 60min for the first time under 310W power, one-time adding by mass ratio 3 when ultrasonic for the first time: The surfactant that the sodium glycocholate of 1:6, sodium cocoate and coconut oil diethanolamide form, the mass ratio of the addition of surfactant and the graphene of step (1) gained surface functionalization is 4: 100, stand still for 30 minutes, and then ultrasonicate for 60 minutes for the second time under 700W power to obtain a well-mixed mixture;

[0062] (3) Centrifuge the mixed solution obtained in step (2) for 25 minutes at a rotating...

Embodiment 3

[0065] The present embodiment provides a kind of preparation method of graphene dispersion liquid, described method comprises the steps:

[0066] (1) Mix graphene and hexadecyltrimethylammonium bromide at a mass ratio of 1:30 at 20°C under anaerobic conditions to obtain surface-functionalized graphene;

[0067] (2) Mix deionized water with the surface-functionalized graphene obtained in step (1) according to the liquid-solid ratio of 1000:1, and use the first ultrasound for 60 minutes at a power of 310W. The surfactant that the sodium glycocholate of ratio 3:1:6, sodium cocoate and coconut oil diethanol amide forms, and adds completely when the first ultrasonic finishes, the addition of surfactant and step (1 ) The mass ratio of the graphene of gained surface functionalization is 4:100, leave standstill 30min, then ultrasonic 60min for the second time under 700W power, obtain the mixed solution of mixing;

[0068] (3) Centrifuge the mixed solution obtained in step (2) for 25 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electron mobility | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap