Method for large-scale preparation of modified activated carbon

A large-scale preparation, activated carbon technology, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problems of unreliable loading, unsatisfactory catalysis, etc., achieve strong catalytic degradation ability, simple and easy preparation method, environmental protection friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The preparation method of this implementation example is realized like this, comprises the steps:

[0030] Get 1000mL concentration and be the aqueous solution of 0.5mg / ml graphene oxide, ultrasonic dispersion 1h, obtain the dispersion liquid of uniform graphene oxide; Then add 50mg tungsten oxide (WO 3 ) nanoparticles and ultrasonically disperse them for 0.5 h, then add 3.5 g of graphene while stirring, and continue stirring for 10 h; finally, immerse the commercial activated carbon in the above mixed dispersion, take it out after the adsorption is saturated, and place it in a 40°C oven for drying.

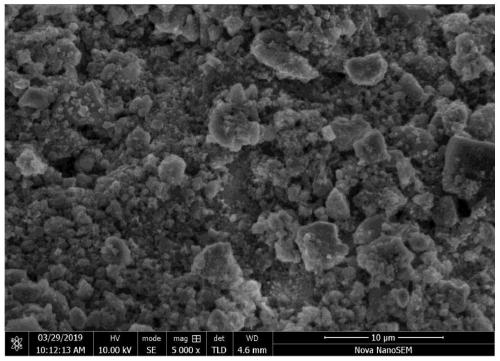

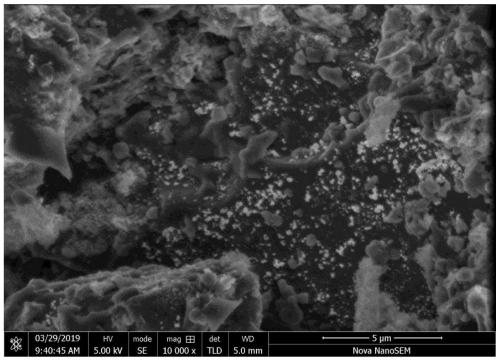

[0031] figure 1 It is the scanning electron micrograph of unmodified activated carbon; figure 2 Scanning electron microscope picture of modified activated carbon, it can be seen that tungsten oxide particles are loaded on activated carbon.

Embodiment 2

[0033] Get 1000mL concentration and be the aqueous solution of 1mg / ml graphene oxide, ultrasonic dispersion 1h, obtain the dispersion liquid of uniform graphene oxide; Then add 1000mg manganese oxide (MnO 2 ) nanoparticles and ultrasonically disperse for 1 h, then add 3 g of graphene while stirring, and continue stirring for 5 h; finally, immerse the activated carbon in the above mixed dispersion, take it out after the adsorption is saturated, and place it in an oven at 250 ° C for drying.

[0034] The resulting SEM image is similar to figure 2

Embodiment 3

[0036] Get 1000mL concentration and be the aqueous solution of 3mg / ml graphene oxide, ultrasonic dispersion 2h, obtain the dispersion liquid of uniform graphene oxide; Then add 15g iron oxide (Fe 2 o 3 ) and ultrasonically disperse the nanomaterials for 1 h, then add 1.5 g of graphene while stirring, and continue stirring for 3 h; finally, immerse the activated carbon in the above mixed dispersion, take it out after the adsorption is saturated, and place it in an oven at 150 ° C for drying.

[0037] The resulting SEM image is similar to figure 2

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com