A kind of preparation method of methyldimethoxysilane

A technology of methyldimethoxysilane and magnetic stirring device, which is applied in the fields of chemical instruments and methods, compounds of group 4/14 elements of the periodic table, organic chemistry, etc., and can solve the problems of little significance in industrial production and difficult to handle high Problems such as boiling matter and methanol by-products are difficult to achieve the effects of reducing equipment requirements, improving product quality, and reaction process safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

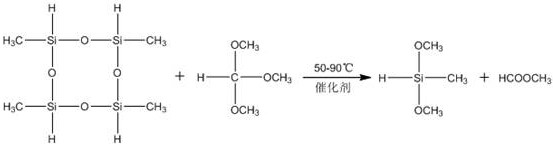

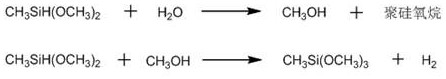

Method used

Image

Examples

Embodiment 1

[0029] Add 120g of 1,3,5,7-tetramethylcyclotetrasiloxane, 212g of trimethyl orthoformate, 6.64g of methanol, and phenylglycidyl ether to a 500mL three-neck flask equipped with a magnetic stirring device and a distillation device. 0.33g and concentrated sulfuric acid 1.33g. Stirring was started, and the temperature of the system was raised to 55°C for 4 hours; then the temperature was slowly raised to 80°C to continue the reaction for 1 hour. From the beginning of heating to the end of the reaction, all the distillates are collected with a receiving bottle to obtain the synthetic crude product. The crude product was then subjected to atmospheric distillation, and the fraction at 60-61°C was collected to obtain 210.2 g of methyldimethoxysilane product. Through GC analysis, the product molar yield is 98.6%, and the main content is 99.5%.

Embodiment 2

[0031] 120g of 1,3,5,7-tetramethylcyclotetrasiloxane, 212g of trimethyl orthoformate, 3.32g of methanol, methyl (ethyl ) glycidyl ether 0.33g and concentrated sulfuric acid 1.66g. Stirring was started, and the temperature of the system was raised to 60°C for 4.5 hours; then the temperature was slowly raised to 85°C to continue the reaction for 1 hour. From the beginning of heating to the end of the reaction, all the distillates are collected with a receiving bottle to obtain the synthetic crude product. The crude product was then subjected to atmospheric distillation, and the fraction at 60-61°C was collected to obtain 207.0 g of methyldimethoxysilane product. Through GC analysis, the product molar yield is 96.9%, and the main content is 99.3%. Stabilizers are epoxy compounds such as epoxy styrene, 1,2-epoxy-3-phenylpropane, and ethylene glycol glycidyl ether.

Embodiment 3

[0033] 120g of 1,3,5,7-tetramethylcyclotetrasiloxane, 212g of trimethyl orthoformate, 9.96g of methanol, ethylene glycol glycidol Ether 0.66g and p-toluenesulfonic acid 0.67g. Stirring was started, and the temperature of the system was raised to 50°C for 5 hours; then the temperature was slowly raised to 90°C to continue the reaction for 1 hour. From the beginning of heating to the end of the reaction, all the distillates are collected with a receiving bottle to obtain the synthetic crude product. The crude product was then distilled at atmospheric pressure, and the fraction at 60~61°C was collected to obtain 208.4g of methyldimethoxysilane product. Through GC analysis, the product molar yield is 97.4%, and the main content is 99.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com