Polyolefin antibacterial master batch, preparation thereof, and application thereof for preparing antibacterial polycondensate

A technology of antibacterial masterbatch and polyolefin, which is applied to the application field of polyolefin antibacterial masterbatch and its preparation and preparation of antibacterial polycondensate, can solve the problems of decreased antibacterial effect, difficult antibacterial for a long time, dissolution loss and the like, and achieves rapid The effect of killing bacteria, the technical scheme is simple, flexible and easy to operate, and easy to prepare for large-scale industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

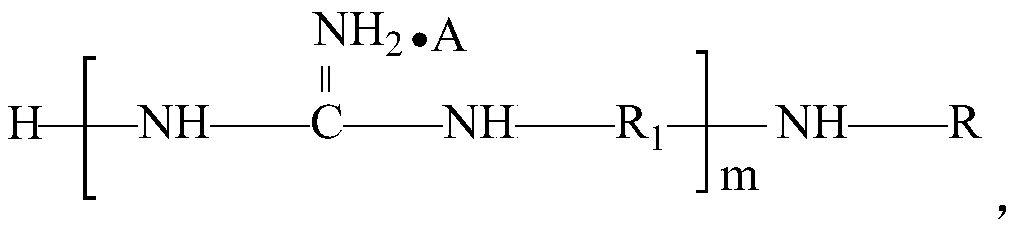

[0044] Weigh 48.5g of guanidine hydrochloride and 46.5g of hexamethylenediamine into a three-necked flask, and place them in an oil bath equipped with mechanical stirring. Stir the reaction at 100°C for 1.5 hours, then continue to raise the temperature to 160°C for 4 hours. Then 20g of dodecylamine was added, and after 1 hour, the temperature was raised to 175° C. and the reaction was continued for 3 hours. Finally, the unreacted monomer was removed by vacuuming, and poured out while hot to obtain the guanidinium salt antibacterial agent.

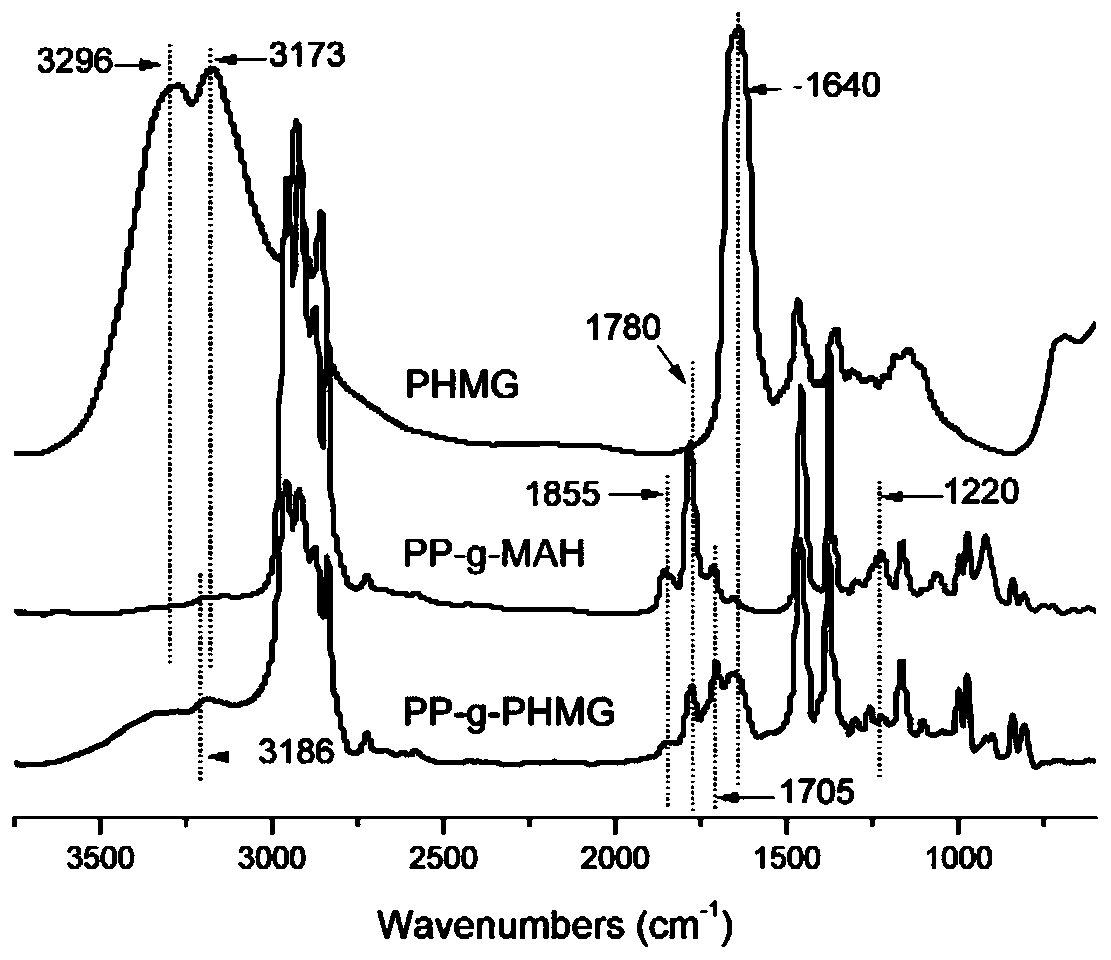

[0045] In the second step, 8g of the above-mentioned synthetic guanidinium salt antibacterial agent and 60g of polypropylene grafted maleic anhydride are melted and reacted in a torque rheometer. material.

[0046] The last step is to prepare antibacterial polyester or nylon, and the concentration of antibacterial agent is respectively 0.5wt%, 1.0wt%, 1.5wt% and 2.0wt%. Specifically, polyester or nylon 67, 64, 61, and 58 g were weighed, a...

Embodiment 2

[0048] In the first step, weigh 38.2 g of guanidine hydrochloride, 51.1 g of hexamethylenediamine and 16.5 g of metformin hydrochloride in a three-necked flask, and place in an oil bath equipped with mechanical stirring. Stir and react at 100°C for 1.5 hours, then continue to heat up to 160°C for 4 hours, further raise the temperature to 175°C and continue to react for 3 hours, pour out while hot to obtain the guanidinium salt antibacterial agent.

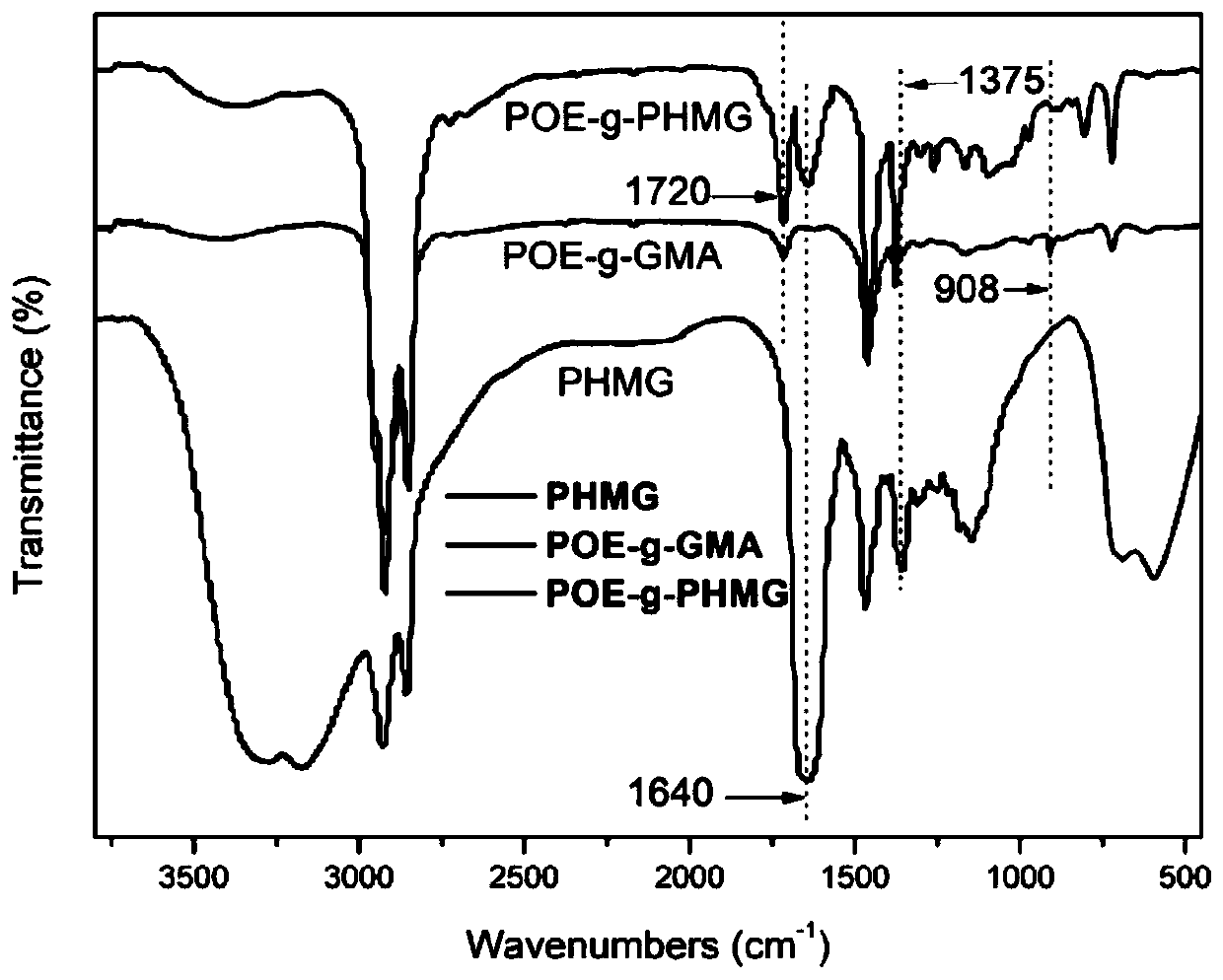

[0049] In the second step, 6g of the above-mentioned synthetic guanidinium salt antibacterial agent and 60g of ethylene-octene copolymer grafted glycidyl methacrylate are melt-reacted in a torque rheometer, and the reaction conditions are 160°C, 50rpm and 15min, to obtain Polyolefin functionalized antimicrobial masterbatch.

[0050] The last step is to prepare antibacterial polyester or nylon, and the concentration of antibacterial agent is respectively 0.5wt%, 1.0wt%, 1.5wt% and 2.0wt%. Specifically, 66, 62, 58, and 54 g of polye...

Embodiment 3

[0052] In the first step, weigh 47.8g of guanidine hydrochloride and 45.2g of hexamethylenediamine and put them in the first three-necked flask, and place them in an oil bath equipped with mechanical stirring. Stir the reaction at 100°C for 1.5 hours, then continue to heat up to 160°C for 3.5 hours. Then 27g of octadecylamine was added, and after 1.5 hours of reaction, the temperature was raised to 175° C. to continue the reaction for 3 hours. Finally vacuumize to remove the unreacted monomer, and pour it out while hot to obtain the guanidinium salt antibacterial agent.

[0053] In the second step, 6g of the above-mentioned synthesized guanidinium salt antibacterial agent and 60g of polyethylene grafted maleic anhydride are melted and reacted in a torque rheometer. material.

[0054] The last step is to prepare antibacterial polyester or nylon, and the concentration of antibacterial agent is respectively 0.5wt%, 1.0wt%, 1.5wt% and 2.0wt%. Specifically, polyester or nylon 66...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com