Low VOC waterborne epoxy zinc-rich primer and preparation method thereof

A technology of water-based epoxy zinc-rich primer, which is applied in the field of coatings, can solve the problems of poor storage stability of the container body, high specific gravity, high zinc content of water-based epoxy zinc-rich primer, etc., to achieve improved coating effect and low hygroscopicity , Improve the effect of storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

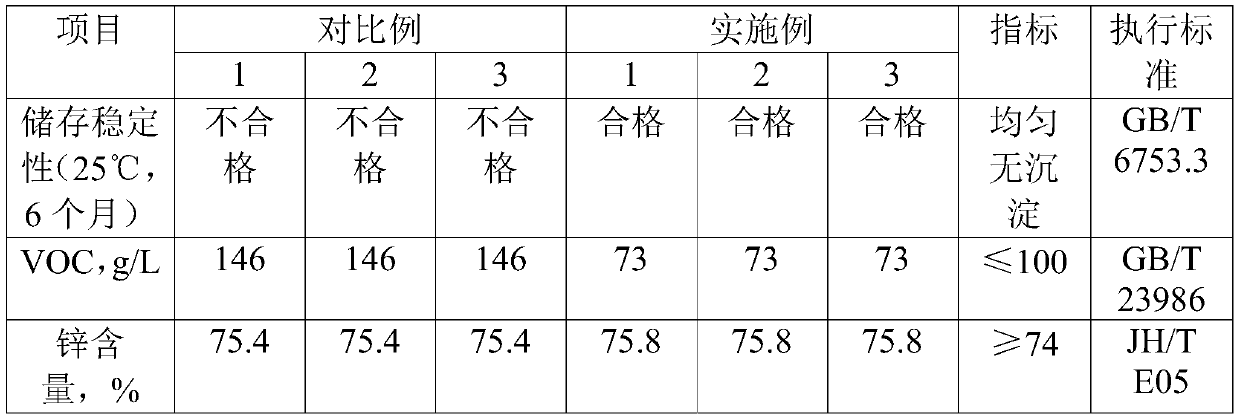

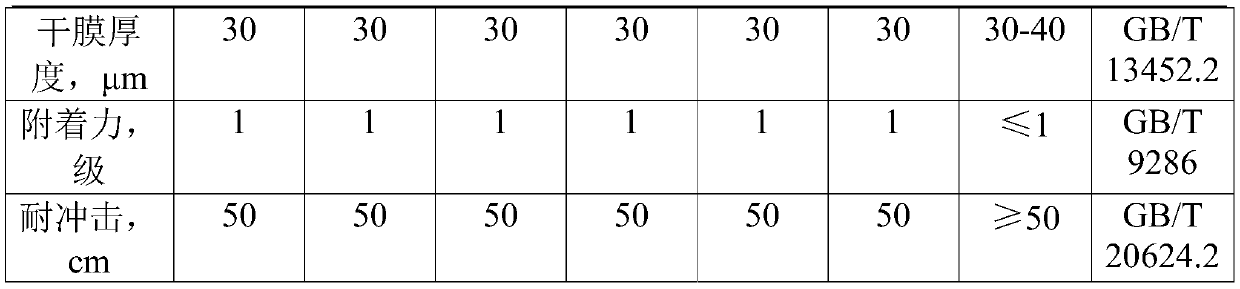

Examples

Embodiment 1

[0035] A low-VOC waterborne epoxy zinc-rich primer, including A component and B component, the weight ratio of A component and B component is 5:2.

[0036] Among them, component A includes the following raw materials by weight: 2 parts of wetting and dispersing agent Levelol W-409, 5 parts of thickening agent NATROSOL Plus 330, 90 parts of isopropanol as film-forming aid, and 10 parts of leveling agent BYK-AQ , Anti-settling agent Bentone AD 60 parts, anti-settling agent AEROSIL R816 2 parts, 8500 mesh superfine talc 20 parts, 800 mesh zinc powder 1600 parts, epoxy curing agent resin ANCAMINE 1618 60 parts, adhesion promoter ADDID 900 12 parts , Catalyst CYCAT 4045 5 shares;

[0037] The B component includes the following raw materials by weight: 50 parts of deionized water, 3302 parts of thickener NATROSOL Plus, 1 part of wetting and dispersing agent Levelol W-409, modified bisphenol A epoxy emulsion Epikote6520-WH-53A 390 Parts, 1 part defoamer TEGO-901W, 1795 parts anti-flash r...

Embodiment 2

[0049] A low-VOC waterborne epoxy zinc-rich primer, including A component and B component, the weight ratio of A component and B component is 5:2;

[0050] Among them, component A includes the following raw materials by weight: 1.5 parts of wetting and dispersing agent Levelol W-409, 4 parts of thickening agent NATROSOL Plus 330, 90 parts of isopropanol as film forming aid, and 10 parts of leveling agent BYK-AQ , Anti-settling agent Bentone AD 60 parts, anti-settling agent AEROSIL R816 2 parts, 8500 mesh superfine talc 20 parts, 800 mesh zinc powder 1600 parts, epoxy curing agent resin ANCAMINE 1618 60 parts, adhesion promoter ADDID 900 12 parts , Catalyst CYCAT 4045 5 shares;

[0051] The B component includes the following raw materials in parts by weight: 50 parts of deionized water, 3303 parts of thickener NATROSOL Plus, 1.5 parts of wetting and dispersing agent Levelol W-409, and modified bisphenol A epoxy emulsion Epikote6520-WH-53A 390 Parts, 1 part of defoamer TEGO-901W, 17...

Embodiment 3

[0063] A low-VOC waterborne epoxy zinc-rich primer, including A component and B component, the weight ratio of A component and B component is 5:2;

[0064] Among them, component A includes the following raw materials by weight: 1 part of wetting and dispersing agent Levelol W-409, 3 parts of thickening agent NATROSOL Plus 330, 90 parts of isopropanol as film forming aid, and 10 parts of leveling agent BYK-AQ , Anti-settling agent Bentone AD 60 parts, anti-settling agent AEROSIL R816 2 parts, 8500 mesh superfine talc 20 parts, 800 mesh zinc powder 1600 parts, epoxy curing agent resin ANCAMINE 1618 60 parts, adhesion promoter ADDID 900 12 parts , Catalyst CYCAT 4045 5 shares;

[0065] The B component includes the following raw materials by weight: 50 parts of deionized water, 3304 parts of thickener NATROSOL Plus, 2 parts of wetting and dispersing agent Levelol W-409, and modified bisphenol A epoxy emulsion Epikote6520-WH-53A 390 Parts, 1 part of defoamer TEGO-901W, 1795 parts of an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com