A high-performance aromatic polymer fiber and its preparation method

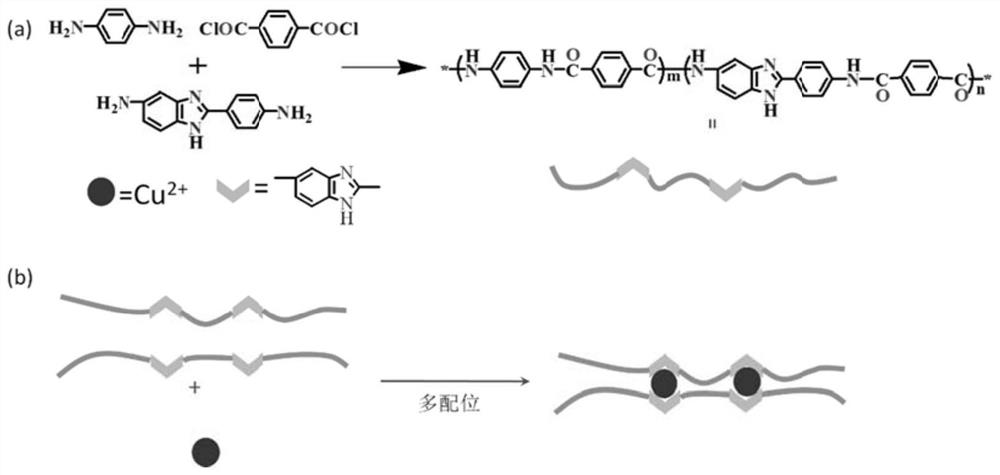

An aromatic polymer, high-performance technology, applied in the direction of fiber processing, fiber type, single-component copolyamide rayon, etc., which can solve the unfavorable macromolecular conformational transition, difficulty in molecular motion, and inability to realize benzimidazole based Co-ordination reactions occur at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1 Preparation of aromatic polymer fiber and composite material thereof of the present invention

[0040] 1, the preparation of aromatic polymer fiber of the present invention

[0041] First, the aromatic polymer is obtained by polymerization according to the monomer molar ratio TPC:PDA:PABZ=10:5:5, and then the aramid primary fiber of the aromatic polymer is obtained by wet spinning, and is soaked statically at 80°C in Contains CuCl 2(mass fraction 2%) in the DMSO / water mixed solution (DMSO volume fraction is 10%), after reacting for 60mins, dry, then carry out tension-free static heat treatment under 360 ℃, nitrogen atmosphere, obtain finished fiber, promptly the present invention aromatic polymer fibers.

[0042] 2, the preparation of composite material of the present invention

[0043] Add the aromatic polymer fiber obtained in step 1 to epoxy resin (the mass fraction of the fiber is 50%) to prepare the corresponding composite material.

Embodiment 2

[0044] Embodiment 2 Preparation of the aromatic polymer fiber of the present invention and its composite material

[0045] 1, the preparation of aromatic polymer fiber of the present invention

[0046] First, the aromatic polymer is obtained by polymerizing according to the monomer molar ratio TPC:PDA:PABZ=10:3:7, and then the aramid primary fiber of the aromatic polymer is prepared by wet spinning, and soaked statically at 50°C in Contains CuSO 4 (mass fraction 0.01%) in the DMAc / water mixed solution (DMAc volume fraction is 5%), after reacting for 30mins, dry, then carry out tension-free static heat treatment under 360 ℃, nitrogen atmosphere, obtain finished fiber, promptly the present invention aromatic polymer fibers.

[0047] 2, the preparation of composite material of the present invention

[0048] Add the aromatic polymer fiber obtained in step 1 to epoxy resin (the mass fraction of the fiber is 50%) to prepare the corresponding composite material.

Embodiment 3

[0049] Embodiment 3 Preparation of the aromatic polymer fiber of the present invention and its composite material

[0050] 1, the preparation of aromatic polymer fiber of the present invention

[0051] First, the aromatic polymer is obtained by polymerizing according to the monomer molar ratio TPC:PDA:PABZ=10:7:3, and then the aramid primary fiber of the aromatic polymer is obtained by wet spinning, and is soaked statically at 90°C in Contains CuCl 2 (mass fraction 10%) in the NMP / water mixed solution (NMP volume fraction is 30%), after reacting for 5mins, dry, then carry out tension-free static heat treatment under 360 ℃, nitrogen atmosphere, obtain finished fiber, promptly the present invention aromatic polymer fibers.

[0052] 2, the preparation of composite material of the present invention

[0053] Add the aromatic polymer fiber obtained in step 1 to epoxy resin (the mass fraction of the fiber is 50%) to prepare the corresponding composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com