Special powder for steamed vermicelli rolls and preparation method thereof

A technology for special powder and sausage powder, applied in the field of sausage powder special powder and its preparation, can solve the problems of hidden dangers of food safety, single type, dark yellow color, etc., and achieve simple and fast method, high production efficiency and high whiteness value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

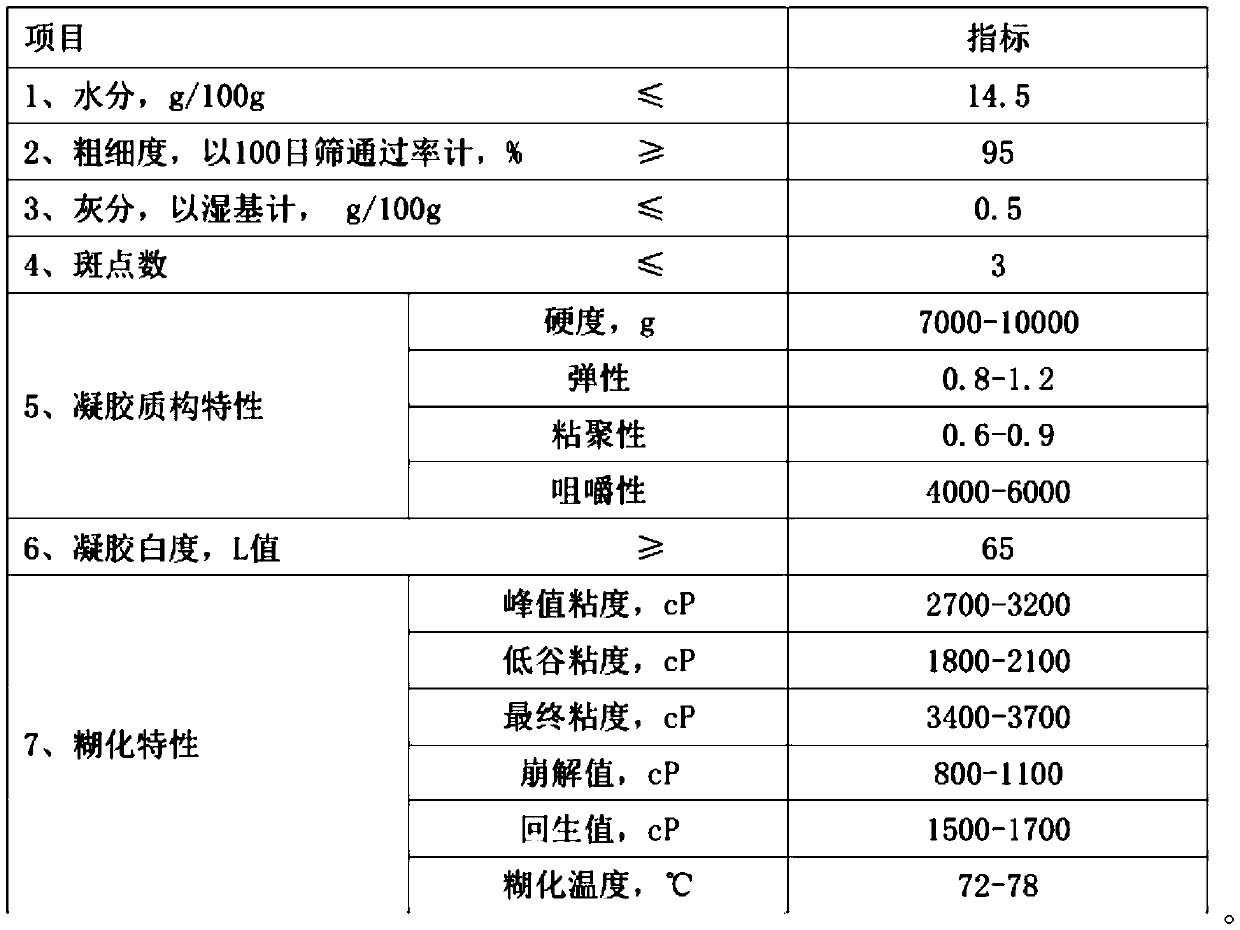

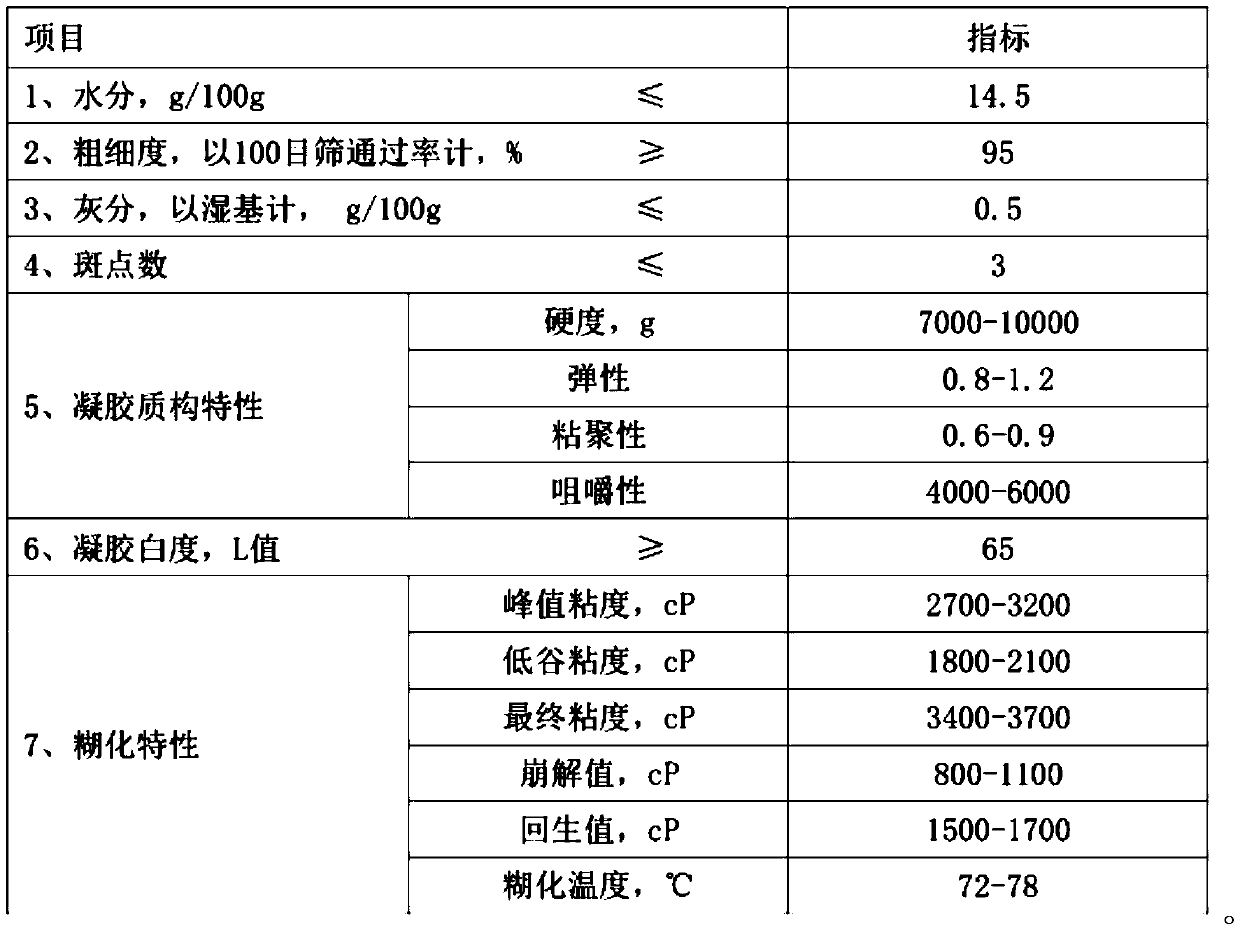

[0032] 1. Preparation of special powder gel and determination of texture properties:

[0033] (1) Preparation of rice flour gel: add water to the rice flour to form 25% (dry basis) rice milk, then equilibrate at 40°C for 15 minutes, steam for 10 minutes to prepare gel, cool at room temperature, and place in a refrigerator at 4°C Aging overnight in the refrigerator.

[0034] (2) Measuring conditions of gel: probe P / 36, pre-test speed 5mm / s, test speed 1.0mm / s, post-test speed 5mm / s, compression ratio 50%, contact force 5.0g, time between two compressions 2s. The results of parameters such as hardness, elasticity, chewiness and cohesiveness are obtained.

[0035] 2. Determination of pasting properties of special powder

[0036] Viscosity analysis samples are based on 14% water, 3g samples are mixed with 25g distilled water and then analyzed with a rapid viscosity analyzer. The analysis time of the whole sample is 13 minutes, and the analysis conditions are: keep at 50°C for ...

Embodiment 1

[0038] Rice rolls are used as raw materials to prepare rice roll special powder.

[0039] (1) Soak

[0040] Weigh 500g of rice, add 800mL of deionized water, stir evenly, and let stand at room temperature for 40min;

[0041] (2) Grinding

[0042] Adopt wet refining, grind the rice with a beater, pass through an 80-mesh sieve, and the Baume degree of the rice milk is about 14°T.

[0043] (3) Reaction

[0044] Add 1g of neutral protease to the rice milk, with an enzyme activity of 200,000 / U, and react at room temperature for 30 minutes. After the enzymolysis, heat the rice milk to 80°C for 30 minutes to inactivate the enzyme and terminate the reaction.

[0045] (4) drying

[0046] The rice slurry obtained in step (3) is filtered and dried.

[0047] (5) Mixing powder

[0048] Add 100g of wheat starch, 2g of acetylated mono-diglyceride fatty acid esters and 5g of hydroxypropyl starch to the rice flour obtained in step (4), and mix to obtain the special powder for intestine p...

Embodiment 2

[0053] Preparation of Special Rice Noodles with Rice as Raw Material

[0054] (1) Soak

[0055] Weigh 500g of rice, add 1000mL of deionized water, stir evenly, and let stand at room temperature for 30min;

[0056] (2) Grinding

[0057] Adopt wet refining, grind the rice with a beater, pass through an 80-mesh sieve, and remove the sieve. The Baume degree of the rice milk is about 14°T.

[0058] (3) Reaction

[0059] Add 1 g of neutral protease to the rice milk with an enzyme activity of 200,000 / U, and react for 30 minutes at room temperature; after the reaction, boil the rice milk to inactivate the protease.

[0060] (4) drying

[0061] The rice milk that step (3) is obtained is dried naturally.

[0062] (5) Mixing powder

[0063] Add 100g of wheat starch, 5g of hydroxypropyl starch and 1g of soybean polysaccharide to the rice flour obtained in step (4), and mix well to obtain special rice roll powder.

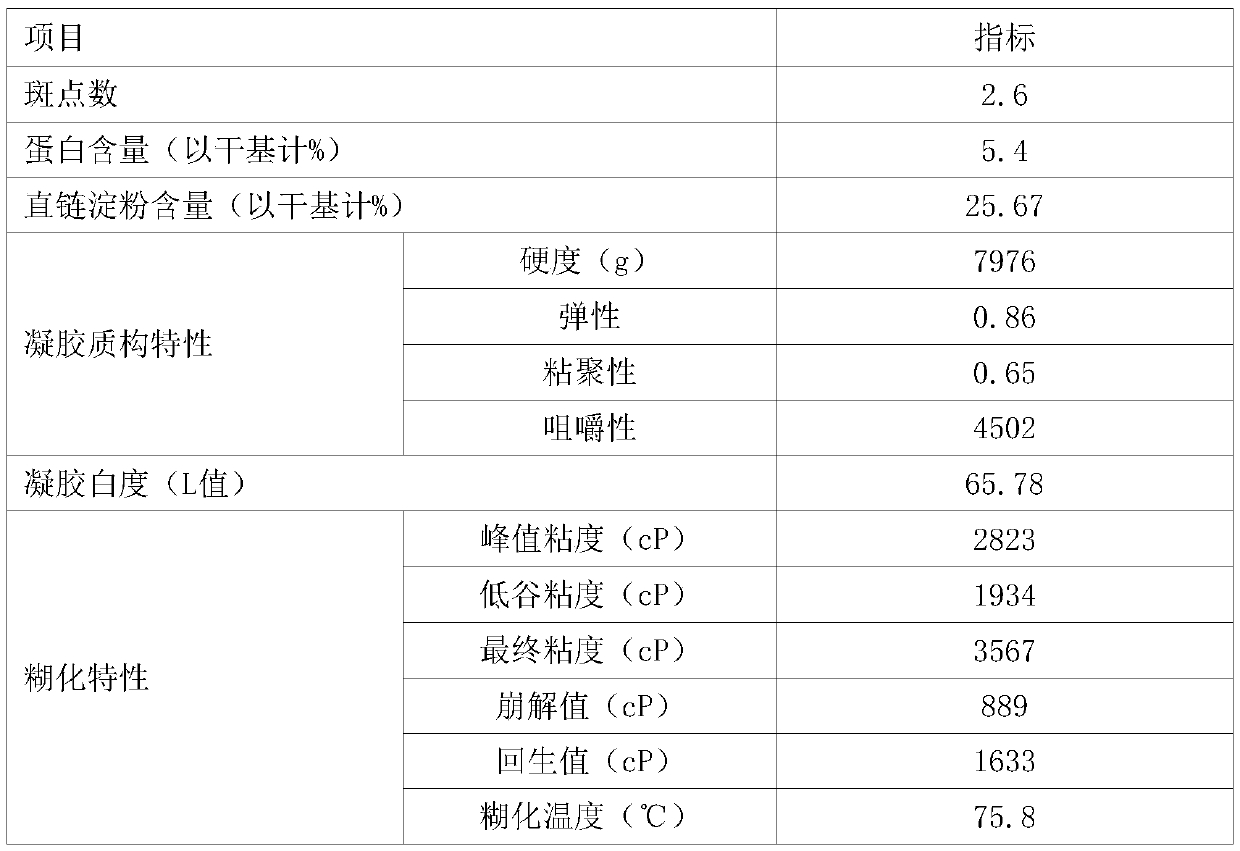

[0064] (6) Index determination

[0065] Table 4

[0066]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com