Preparation method for nanocrystals

A technology of nanocrystals and precursor substances, applied in chemical instruments and methods, inorganic chemistry, phosphide, etc., can solve the problems of difficult control, high cost, low preparation cost, etc., and achieve easy mass production and narrow half-peak width. , the effect of simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

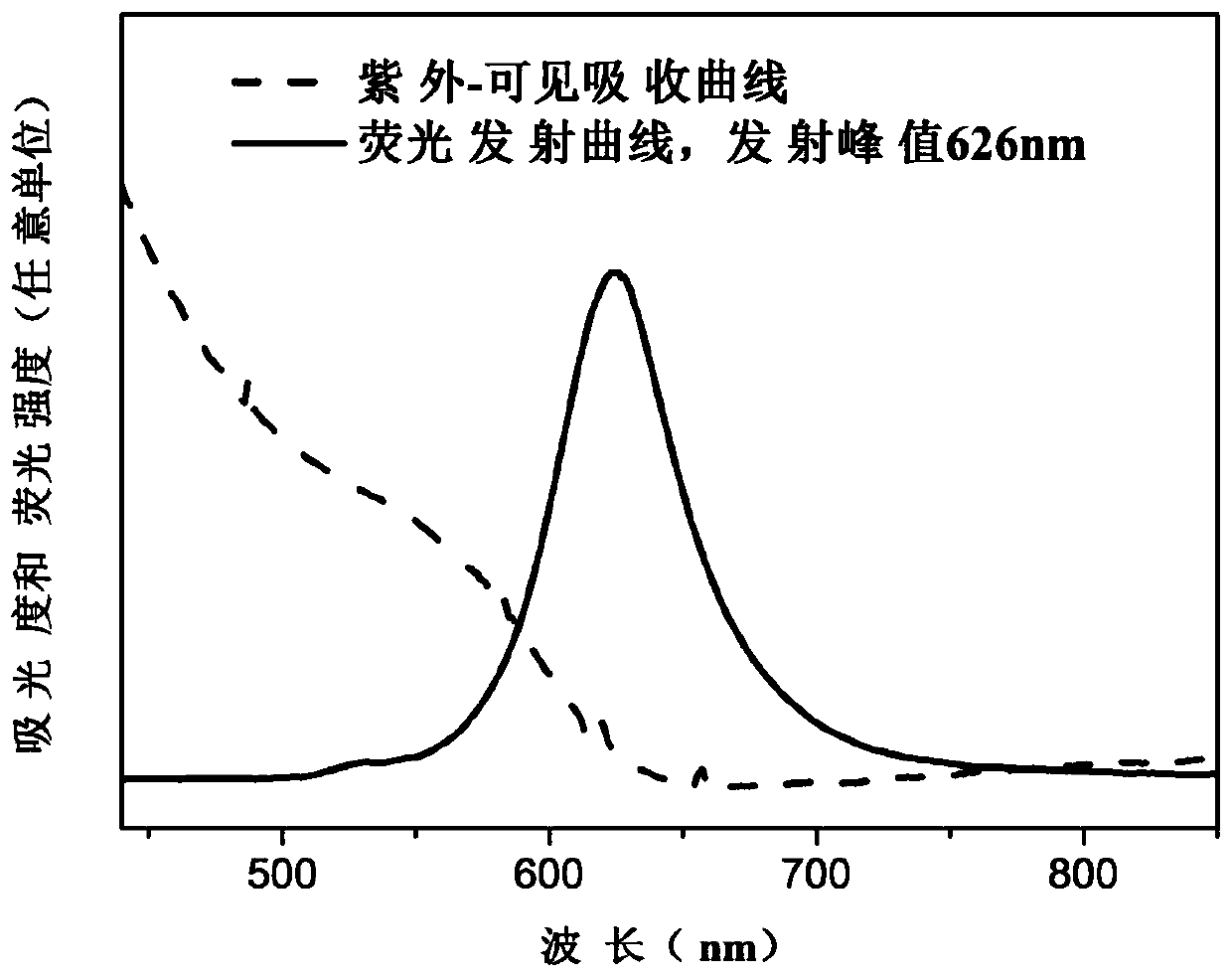

Image

Examples

preparation example Construction

[0026] The invention discloses a method for preparing nanocrystals, which comprises the following steps: quickly adding nanocrystals with relatively uneven particle diameters into an organic solvent with a predetermined temperature in which an electron-donating group compound is dissolved to produce nanocrystals with relatively uniform particle diameters. Crystals, the predetermined temperature in an organic solvent can break the ionic bonds of the nanocrystals.

[0027] The predetermined temperature is a temperature range that can break the ionic bonds of the nanocrystals in the organic solvent, but cannot completely decompose the nanocrystals into ions at the moment of adding, allowing the seeding growth of the nanocrystals. Different nanocrystals correspond to different predetermined temperatures.

[0028] In the present invention, the nanocrystals with relatively uneven particle diameters are instantly contacted with a high-temperature organic solvent, so that the ion bond...

Embodiment 1

[0048] Preparation of indium phosphide nanocrystals with uniform particle size: 1) Mix indium acetate, zinc acetate, octadecanoic acid, and octadecylamine, wherein the molar ratio of indium acetate to zinc acetate is 1:2, and add a small amount of octadecene solvent 2) Heating the mixture to 120°C under vacuum condition, and deoxidizing for 1 hour to obtain the precursor mixed solution of indium acetate and zinc acetate; 3) Heating the mixed solution to 180°C, and injecting Phosphine gas, until the mixed solution becomes light yellow, stop feeding the gas to obtain a relatively inhomogeneous indium phosphide nanocrystal dispersion; Add it into a certain amount of octadecene, stir evenly, and heat up to 245°C to obtain an organic solution at a predetermined temperature; 6) Add the cooled dispersion to a mixed solution of n-hexane and ethanol, centrifuge at high speed, and dissolve the obtained centrifugal precipitate with n-hexane, then add methanol to form The suspension was ...

Embodiment 2

[0050] Preparation of indium phosphide nanocrystals coated with zinc sulfide with uniform particle size: the same as in Example 1, the difference is that step 5) is: adding the indium phosphide nanocrystal dispersion with uneven particle size to 245 In the organic solution at ℃, keep warm for 5 seconds, add sulfur source dissolved in octadecene dropwise, keep warm for 5 minutes, and then lower the temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com