A kind of automobile fuel tank gasoline dewatering agent and preparation method thereof

A technology for automobile fuel tanks and gasoline, which is applied in the petroleum industry, liquid carbon-containing fuels, fuels, etc., can solve the problems of inability to meet the multi-functional requirements of gasoline, inability to achieve technical effects, poor emulsification stability, etc., and achieve significant synergy. , the effect of reducing activation energy and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

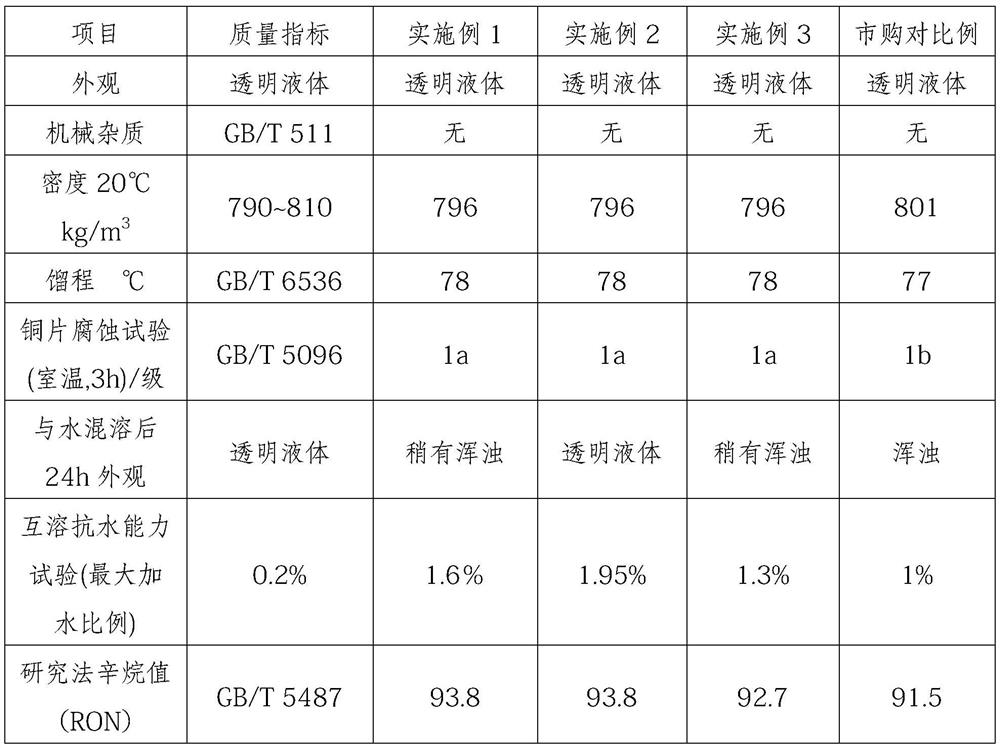

Examples

Embodiment approach

[0030] According to a preferred embodiment, the solubilizer includes triethylene glycol methyl ether and dimethylformamide.

[0031] Among them, solubilization means that substances that are insoluble or slightly soluble in specific solvents become soluble under the action of surface active compounds (ie solubilizers), so solubilizers can convert poorly water-soluble or water-insoluble substances into transparent , the most milky white aqueous solution, and the chemical structure of these poorly water-soluble or water-insoluble substances has not changed during this process. The mixtures obtained are characterized in that poorly water-soluble or water-insoluble substances are present in colloidally dissolved form in associations of molecules of the surface-active compounds forming aqueous solutions, so-called micelles. The resulting solutions are stable single-phase systems that appear visually clear to opalescent and can be prepared without input of energy. In addition, the ...

Embodiment 1

[0081] First add 53% methanol of 1 / 2 of the total amount and 41.5% ethanol of 1 / 2 of the total amount into the closed kettle according to the negative pressure suction mode, continue to pass nitrogen under the closed environment, and stir for 0.5 hours to obtain a mixed solution. stand-by;

[0082] Add accurately measured 0.4% dimethylformamide and 0.15% triethylene glycol methyl ether into the closed kettle in sequence according to negative pressure suction, continue to blow nitrogen in a closed environment, and stir for 0.5 hours;

[0083] Add the remaining methanol and remaining ethanol into the closed kettle according to negative pressure suction, continue to pass nitrogen under the closed environment, and stir for 0.5 hours;

[0084] Add accurately measured 0.5% benzotriazole and 0.6% high base value calcium petroleum sulfonate into the closed kettle sequentially according to the negative pressure suction method, continue to blow nitrogen in a closed environment, and stir...

Embodiment 2

[0088] First add 1 / 2 of the total amount of 53% methanol and 1 / 2 of the total amount of 41.5% methyl ethyl ketone into the closed kettle according to negative pressure suction, continue to blow nitrogen under the closed environment, and stir for 0.5 hours to obtain a mixed solution ,stand-by;

[0089] Add accurately measured 0.4% dimethylformamide and 0.15% triethylene glycol methyl ether into the closed kettle in sequence according to negative pressure suction, continue to blow nitrogen in a closed environment, and stir for 0.5 hours;

[0090] Add the remaining methanol and the remaining methyl ethyl ketone into the closed kettle according to negative pressure suction, continue to pass nitrogen under the closed environment, and stir for 0.5 hours;

[0091] Add accurately measured 0.5% benzotriazole and 0.6% high base value calcium petroleum sulfonate into the closed kettle sequentially according to the negative pressure suction method, continue to blow nitrogen in a closed en...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com