Solar cell, preparation method thereof and photovoltaic module

A solar cell and electrode technology, which is applied in the field of solar cells, can solve the problems of limiting the efficiency of solar cells, the small size of polysilicon thin films, and the difficulty of polysilicon thin films, and achieve the effects of reducing production costs, increasing the lifetime of minority carriers, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

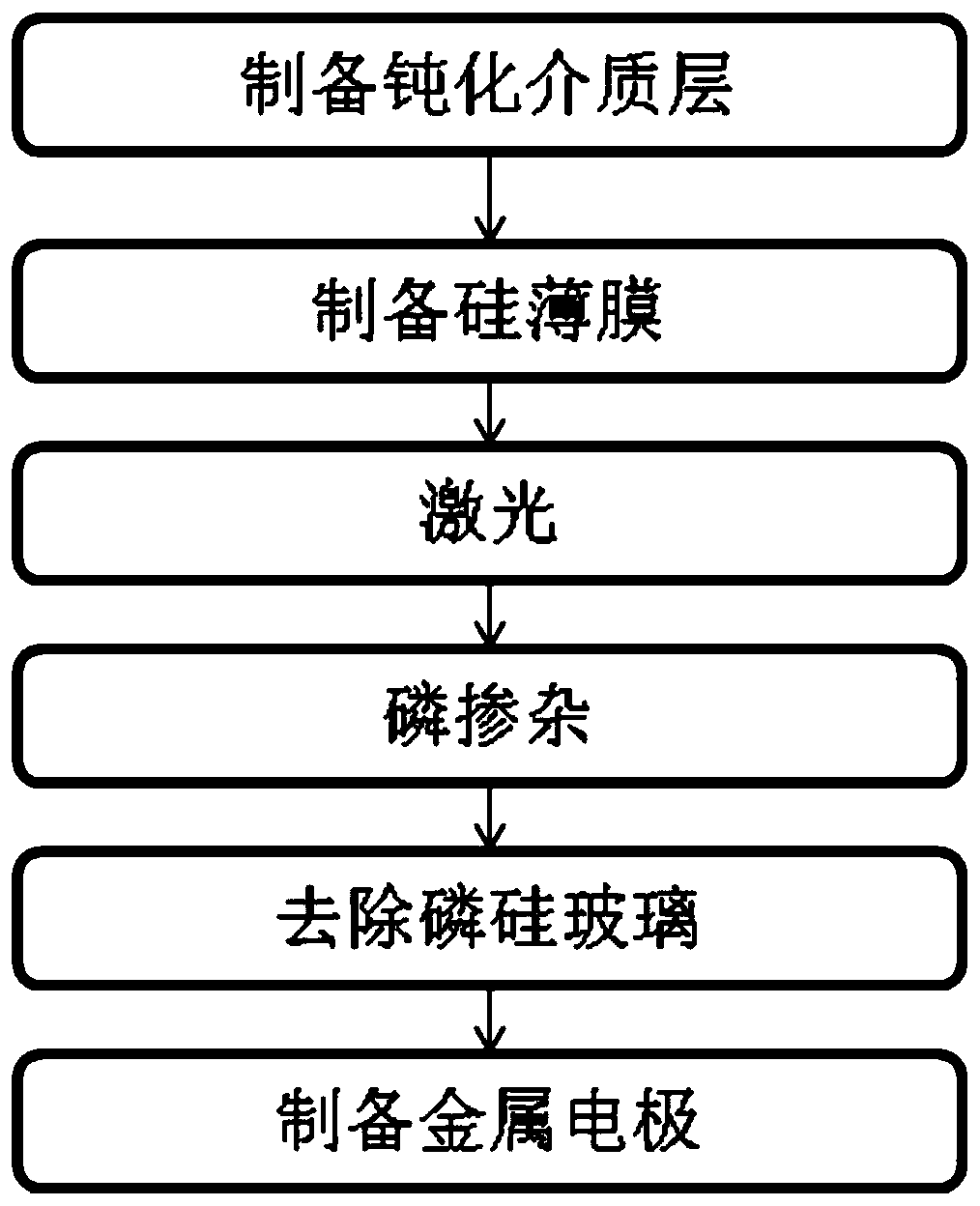

[0100] The present invention also provides the preparation method of the above-mentioned solar cell, such as figure 2 Shown, this preparation method comprises the following steps:

[0101] S1: providing a silicon substrate 1;

[0102] S2, setting a passivation dielectric layer 4 on the silicon substrate 1;

[0103] S3: setting a semiconductor thin film on the passivation medium layer 4;

[0104] S4: removing the semiconductor thin film and the passivation medium layer 4 at the predetermined position to expose a part of the surface of the silicon substrate 1;

[0105] S5: Doping the area exposed on the surface of the silicon base 1 to form a doped area 2 in the area exposed on the surface of the silicon base 1, and the area covered by the semiconductor film and the passivation medium layer 4 on the surface of the silicon base 1 is the non-doped area 3 ;

[0106] S6: forming the electrode 6 in contact with the doped region 2 .

[0107] In the preparation method of the pres...

Embodiment 1

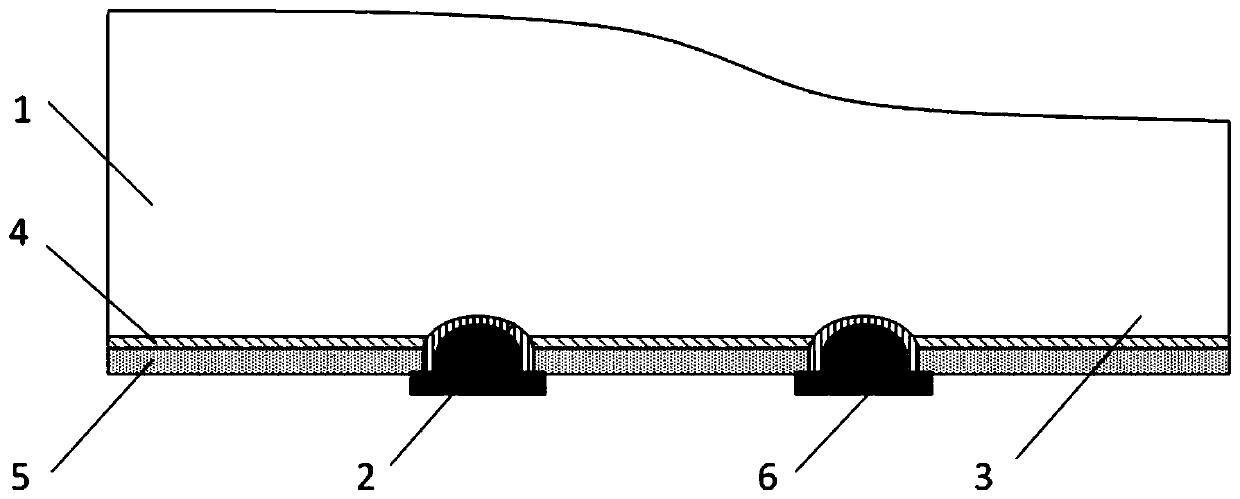

[0120] like figure 1 As shown, the N-type solar cell provided in this embodiment is an N-type solar cell with local doping of the silicon substrate, including an N-type silicon substrate 1, and a partially doped region 2 and a non-doped silicon substrate are provided on the back side of the N-type silicon substrate 1. The impurity area 3 is provided with a passivation medium layer 4 on the surface of the non-doped area 3 of the silicon substrate 1, a doped silicon film is provided on the passivation medium layer 4, and an electrode is provided on the partially doped area 2. 6.

[0121] The surface of the N-type silicon substrate 1 is a textured surface.

[0122] The doped regions 2 and the non-doped regions 3 on the silicon substrate 1 are distributed alternately.

[0123] The doped silicon film is specifically a doped amorphous silicon film with a thickness of 200 nm, and the doping element is the same as that of the local doping region 2 , and the doping element is phospho...

Embodiment 2

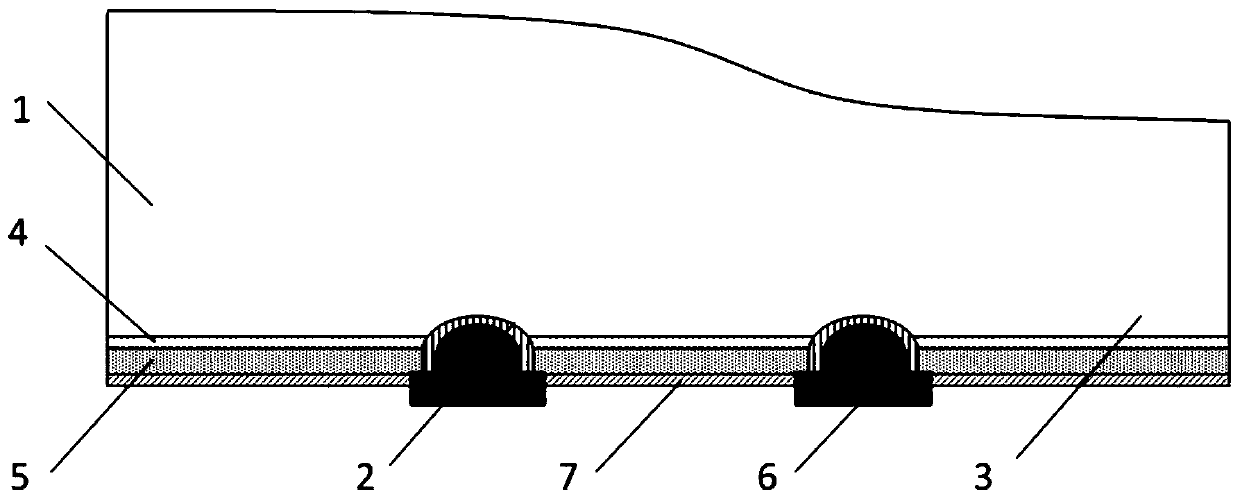

[0136] like image 3 As shown, the N-type solar cell provided in this embodiment is an N-type solar cell with local doping of the silicon substrate, including an N-type silicon substrate 1, and one of the surfaces of the N-type silicon substrate 1 is provided with a local doping region 2 and The non-doped region 3 is provided with a passivation medium layer 4 on the surface of the non-doped region 3 of the silicon substrate 1, and a doped silicon film 5 is provided on the passivation medium layer 4, and the doped silicon film 5 and A silicon nitride film 7 is provided on the partially doped region 2 of the silicon substrate 1 , and a metal contact electrode 6 is provided above the partially doped region 2 of the silicon substrate 1 .

[0137] The metal contact electrode 6 is disposed on the silicon nitride film 7 and corresponds to the position of the local doped region 2 .

[0138] Partially doped regions 2 and non-doped regions 3 of the silicon substrate 1 are distributed a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com