Silicon-carbon anode and preparation method thereof

A silicon carbon and negative electrode technology, applied in battery electrodes, electrical components, circuits, etc., can solve the problems of easy pulverization, large volume expansion rate of silicon carbon negative electrodes, etc., and achieve enhanced adhesion, enhanced toughness, and excellent conductivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

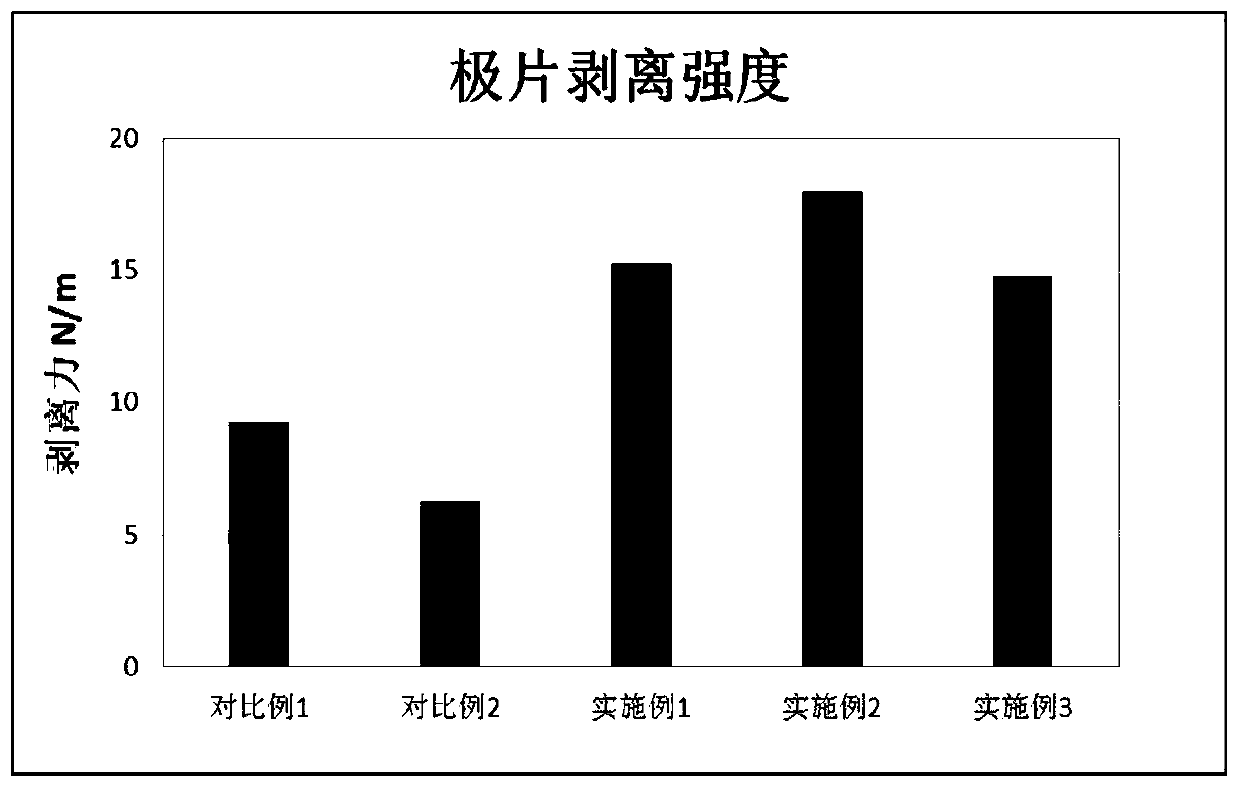

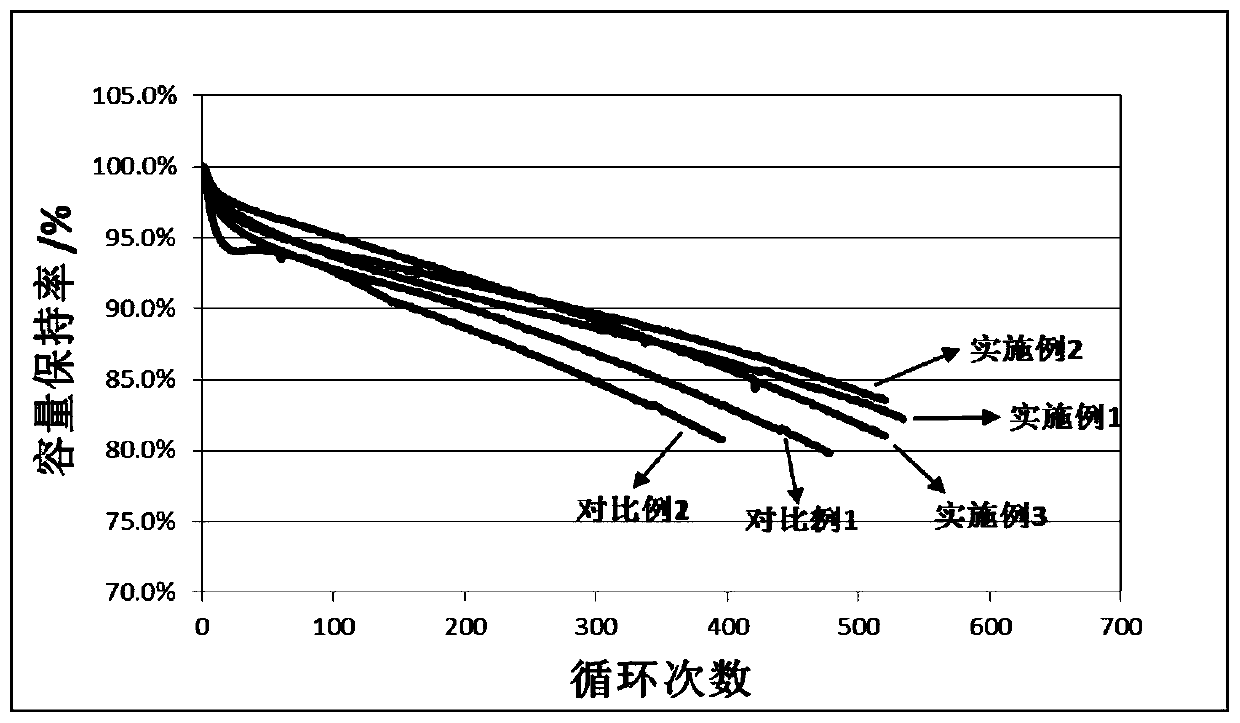

Examples

preparation example Construction

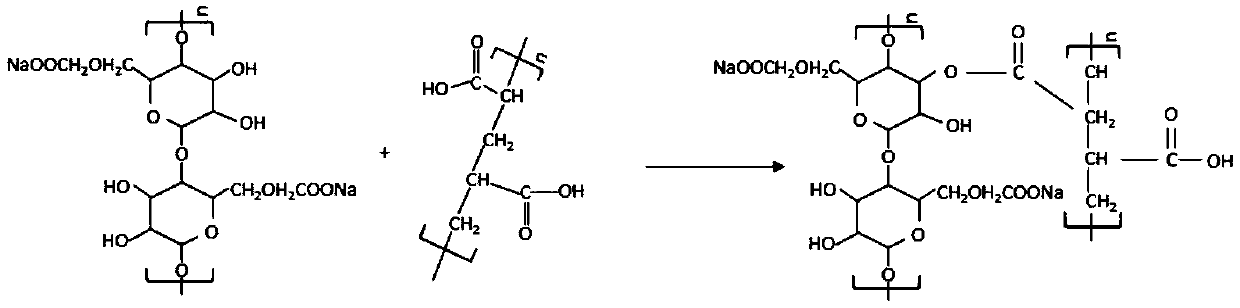

[0089] The preparation method of the silicon carbon negative electrode of the present invention comprises the steps of:

[0090] Dispersing the silicon carbon negative electrode active material, the binder reactant, and the conductive agent in a solvent to prepare a negative electrode slurry, wherein the binder reactant includes polyacrylic acid and sodium carboxymethylcellulose;

[0091] The negative electrode slurry is coated on the current collector, and after baking, a silicon carbon negative electrode is obtained, wherein, during the baking process, polyacrylic acid and sodium carboxymethyl cellulose undergo condensation reaction to form a three-dimensional network polymer.

[0092] In the preparation method of the silicon-carbon negative electrode of the present invention, the baking temperature is 120-200° C., and the baking time is 3-10 minutes.

[0093] The baking temperature is 120-200°C, which can make the polyacrylic acid and sodium carboxymethyl cellulose in the b...

Embodiment 1

[0099] 9.595Kg of graphite powder and silicon oxide powder (graphite powder 7.595Kg, silicon oxide 2Kg), 0.2Kg polyacrylic acid, 0.1Kg sodium carboxymethyl cellulose, 0.005Kg single-walled carbon nanotube (CNT), 0.1Kg Conductive carbon black (SP) was dispersed in deionized water to make a slurry, coated on the surface of copper foil of the negative electrode collector, baked at 150°C to remove the solvent, rolled, and die-cut to obtain a silicon carbon negative electrode.

Embodiment 2

[0101] 9.495Kg of graphite powder and silicon oxide powder (graphite powder 7.095Kg, silicon oxide 2.4Kg), 0.3Kg polyacrylic acid, 0.1Kg sodium carboxymethyl cellulose, 0.005Kg single-walled carbon nanotube (CNT), 0.1 Kg of conductive carbon black (SP) was dispersed in deionized water to make a slurry, coated on the surface of the negative electrode current collector copper foil, baked at 140°C to remove the solvent, rolled, and die-cut to obtain a silicon carbon negative electrode.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com