Machining method of neodymium iron boron powder

A powder processing, NdFeB technology, applied in metal processing equipment, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of NdFeB powder waste, poor dust screening effect, unfavorable screening process, etc., to avoid Slip, screen thoroughly, and ensure the effect of transmission effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

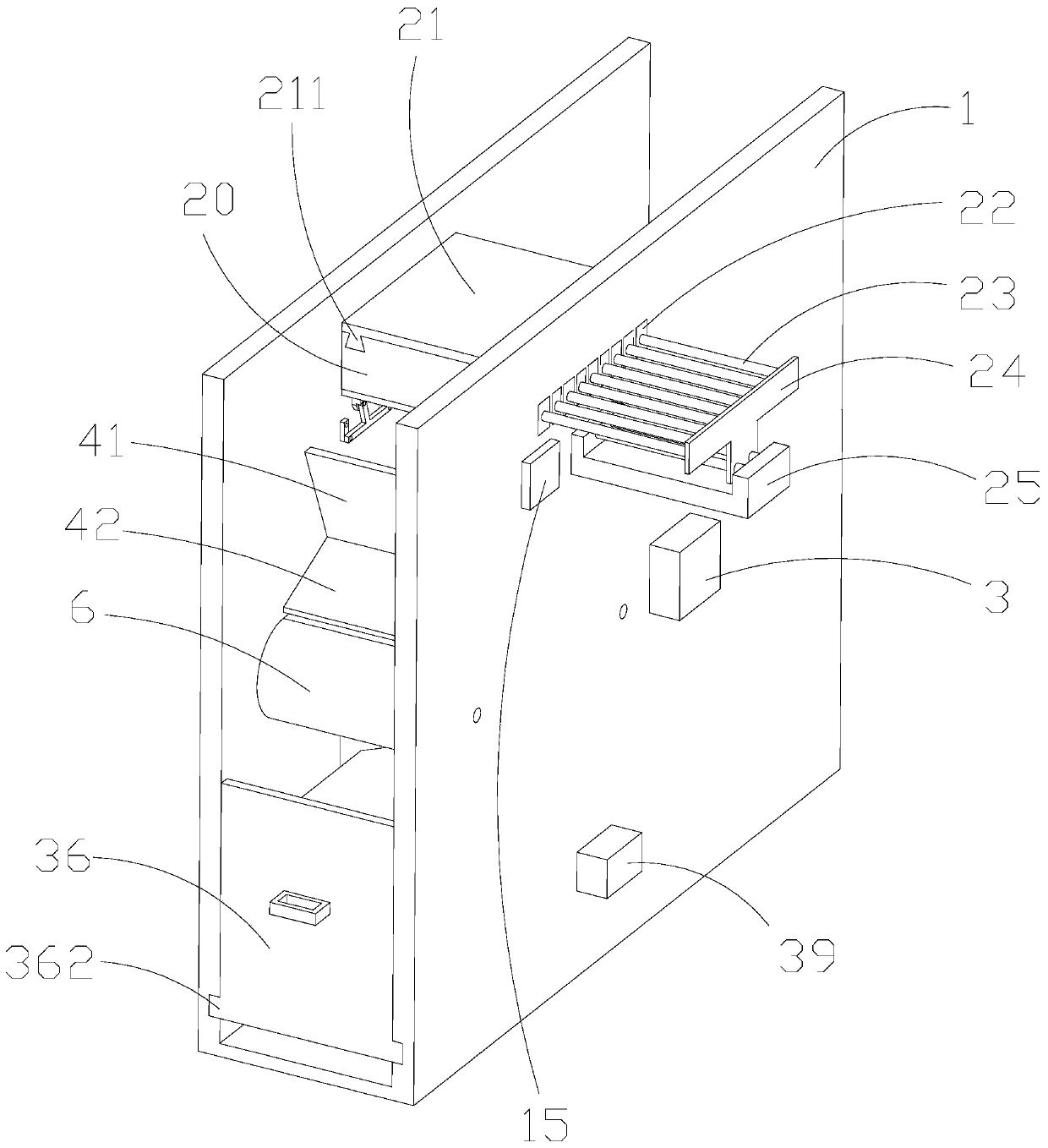

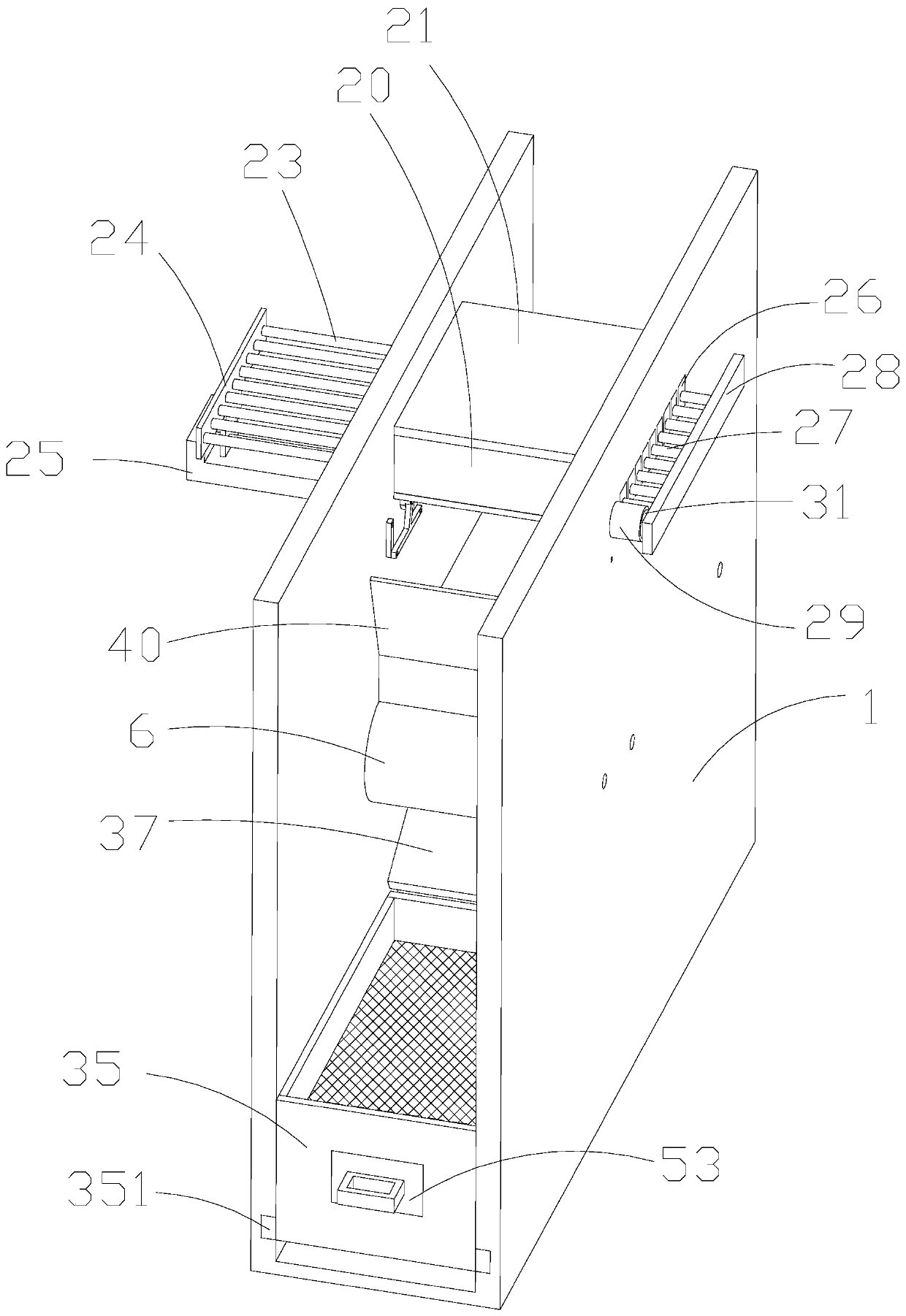

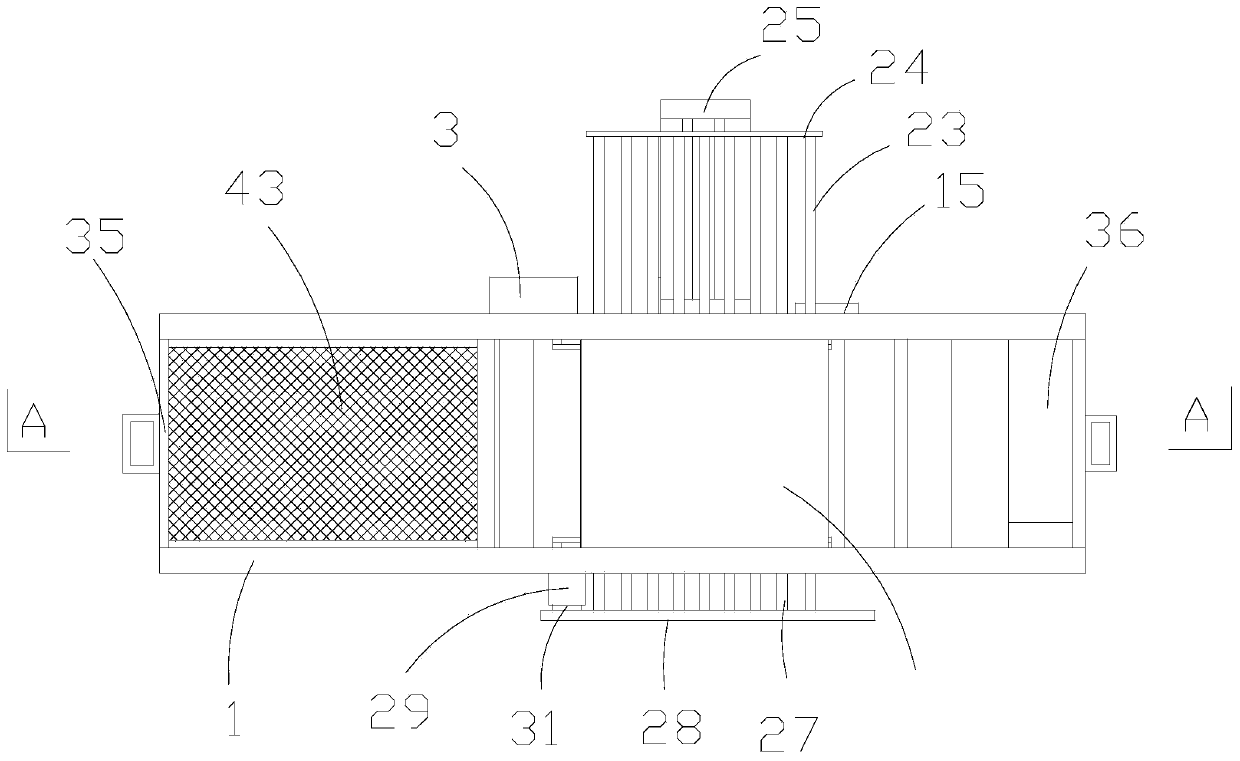

[0027] Such as Figure 1-7 Shown, a kind of NdFeB powder processing method comprises the following steps:

[0028] a. Pretreatment: Remove oxidized powder, coarse particles, dust, screws, rubber bands and other impurities in NdFeB powder through the NdFeB powder screening mechanism;

[0029] b. Forming orientation: press the powder screened in step a into a crush of a certain shape and size, while maintaining the degree of grain orientation obtained in the magnetic field orientation as much as possible;

[0030] c. Oil stripping: Remove the product package pressed and formed in step b in the glove box. When the oil stripping process is carried out, open the gas filling valve of the glove box and the gas filling valve of the auxiliary feeding box to fill in nitrogen; observe the oxygen meter, when The oxygen content drops to 0.05%, before cutting the bag.

[0031] d. Sintering: place the powder in step c in a high-vacuum space, apply high temperature to the powder, make the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com