Ferrite-modified modified carbon fiber cloth electrode, preparation method and application thereof

A carbon fiber cloth, modification and modification technology, applied in chemical instruments and methods, oxidized water/sewage treatment, water/sewage treatment equipment, etc., can solve the problems of low POPs concentration and limited removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

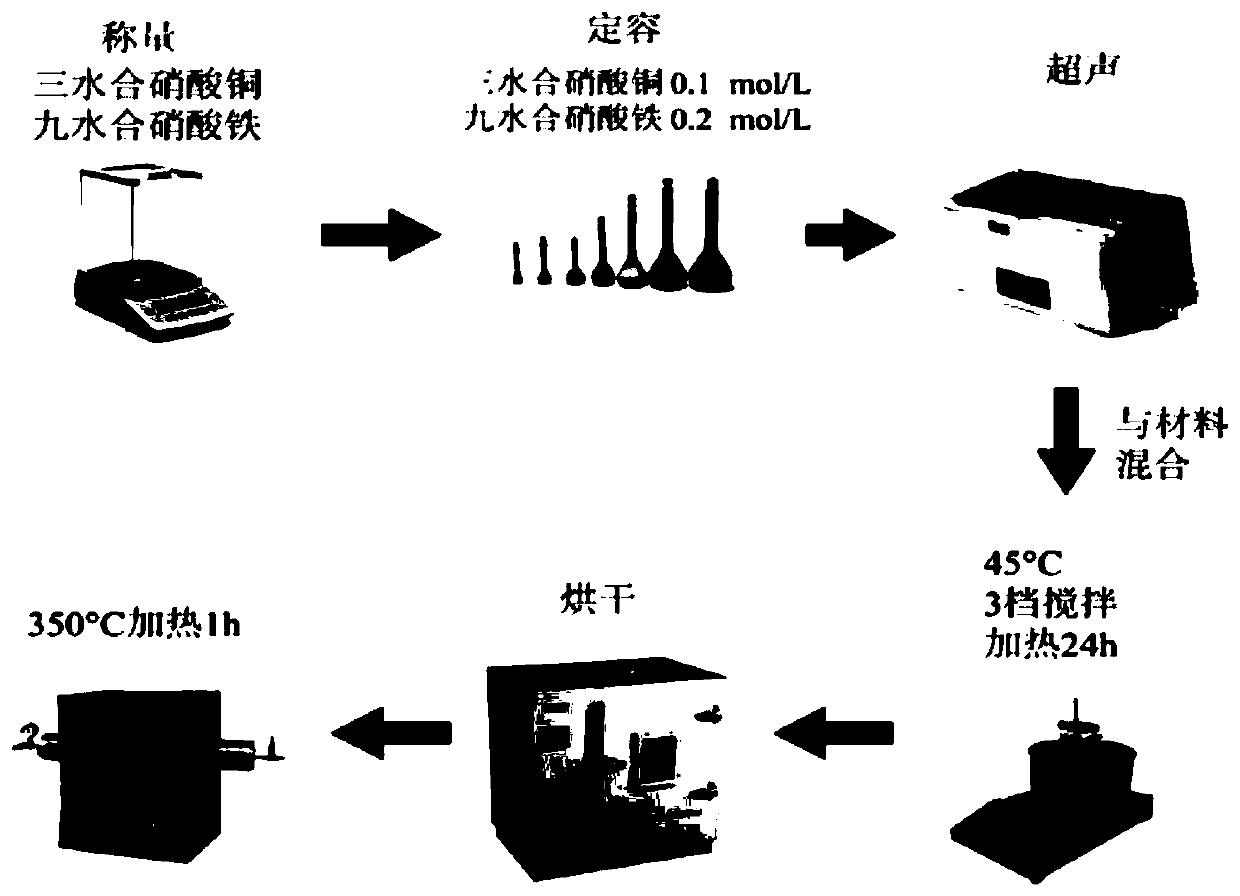

[0102] Embodiment 1 Preparation of ferrite-modified modified carbon fiber cloth electrochemical cathode

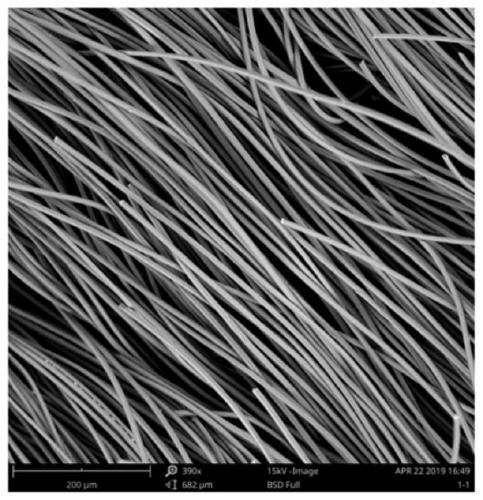

[0103] 1) Cut the original carbon fiber cloth into a circle with a diameter of 3.5 cm, and use a mixture of nitric acid with a mass fraction of 10% and a sulfuric acid solution with a mass fraction of 10% (the volume ratio of nitric acid: sulfuric acid is 3:1) to treat the carbon cloth. After soaking and ultrasonic treatment for 30 minutes, react in a constant temperature reactor at 50°C for 48 hours. After the solution is cooled, wash it with ultrapure water several times to remove surface residue impurities until the pH of the washing solution is neutral, and then in 40 ℃ in a vacuum oven until it reaches a constant quality, and the modified carbon fiber cloth is obtained;

[0104] 2) Soak the above-mentioned modified carbon fiber arrangement in ultrapure water, and then add 0.4mol / L Fe(NO 3 ) 3 9H 2 O and 0.2mol / L Cu(NO 3 ) 2 ·3H 2 O, sonicate for 1 hour to mix ev...

Embodiment 2

[0105] Example 2 Preparation of Ferrite Modified Carbon Fiber Cloth Electrochemical Cathode

[0106] 1) Cut the original carbon fiber cloth into a circle with a diameter of 3.5cm, take 1.5mL of 30wt% H 2 o 2 and 97mL of ultrapure water were placed in a 250mL Erlenmeyer flask, and the pH was adjusted to 3, then 1.5mL of 0.2mol / L Fe was added 2+ Solution (it can be ferrous sulfate or ferric chloride solution), soak the carbon cloth, after 30 minutes of ultrasonic treatment, react in a constant temperature reactor at 50°C for 48 hours, after the solution is cooled, wash it with ultrapure water Several times, remove surface residues and impurities until the pH of the washing liquid is neutral, and then fully dry in a vacuum oven at 40°C until a constant quality is achieved, and the modified carbon fiber cloth is obtained;

[0107] 2) Soak the above-mentioned modified carbon fiber arrangement in ultrapure water, and then add 0.4mol / L Fe(NO 3 ) 3 9H 2 O and 0.2mol / L Cu(NO 3 ) ...

Embodiment 3

[0109] The difference from Example 1 is that the mass fraction of 10% nitric acid and 10% mass fraction of sulfuric acid solution (nitric acid: sulfuric acid volume ratio is 3:1) is replaced by: 0.3mol / L hypochlorous acid , other with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com