Emulsion explosive used in underground mine and preparation method of emulsion explosive

A technology for emulsified explosives and underground mines, which is applied in explosives, non-explosive/non-thermic components, offensive equipment, etc. It can solve the problems of powdery explosives easy to powder, emulsion explosives with low viscosity and fluidity, and poor blasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The embodiment of the present invention also provides a kind of preparation method of underground mining emulsion explosive, comprises the steps:

[0022] (1) prepare materials by weight percentage;

[0023] (2) After mixing ammonium nitrate and water, stir at 85-90°C until the ammonium nitrate is completely dissolved, then add thiourea to the mixed solution, stir and mix evenly, then add acetic acid and anhydrous sodium carbonate to the mixed solution in turn, to obtain water phase material;

[0024] (3) Mix composite wax, paraffin wax, microcrystalline wax, machine oil, polyisobutenyl succinimide, hydrogenated castor oil and Span-80, and heat to 40-45°C to obtain an oil phase material;

[0025] (4) Emulsify the water-phase material and the oil-phase material into an emulsified matrix at 85-95°C, store them in plastic barrels for later use or directly pump them into the silo of the charging vehicle through the pumping system for later use; The emulsified matrix in th...

Embodiment 1

[0031] Embodiment 1 of the present invention provides a kind of underground mining emulsion explosive, wherein,

[0032] The water phase material consists of the following components in terms of weight percentage: 83% of ammonium nitrate, 0.25% of thiourea, 0.17% of acetic acid, 0.03% of anhydrous sodium carbonate, and water added to 100%.

[0033] The oil phase material is composed of the following components in weight percentage: 25% composite wax, 17.5% paraffin wax, 4.5% microcrystalline wax, 0.2% motor oil, 8% polyisobutenyl succinimide, 2% hydrogenated castor oil, Span-80 added to 100%.

[0034] The sensitizing material consists of the following components in weight percentage: 92% of sodium nitrite and 8% of water.

[0035] The water phase material, the oil phase material and the sensitizing material are mixed according to a weight ratio of 88.5:11.5:0.62.

[0036] The emulsion explosive for underground mining is prepared by the following method:

[0037] (1) Mix amm...

Embodiment 2

[0042] Embodiment 2 of the present invention provides a kind of underground mining emulsion explosive, wherein,

[0043] The water phase material consists of the following components in terms of weight percentage: 82.5% of ammonium nitrate, 0.25% of thiourea, 0.16% of acetic acid, 0.03% of anhydrous sodium carbonate, and water added to 100%.

[0044] The oil phase material is composed of the following components in weight percentage: 22% composite wax, 17% paraffin wax, 4.3% microcrystalline wax, 0.1% machine oil, 7.5% polyisobutenyl succinimide, 1% hydrogenated castor oil, Span-80 added to 100%.

[0045] The sensitizing material consists of the following components in weight percentage: 91% of sodium nitrite and 9% of water.

[0046] The water phase material, the oil phase material and the sensitizing material are mixed in a weight ratio of 85:15:0.4.

[0047] The emulsion explosive for underground mining is prepared by the following method:

[0048] (1) Mix ammonium nitra...

PUM

| Property | Measurement | Unit |

|---|---|---|

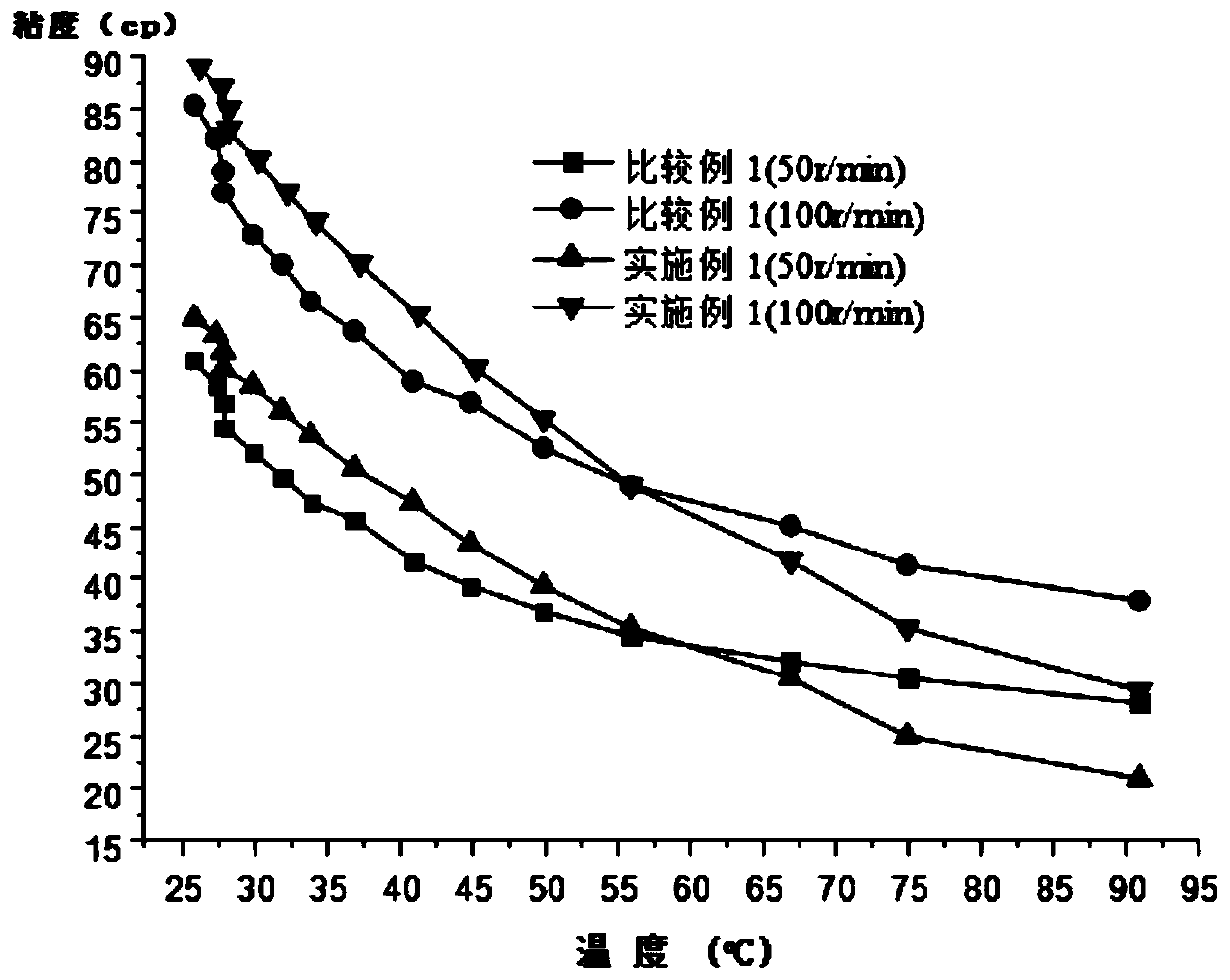

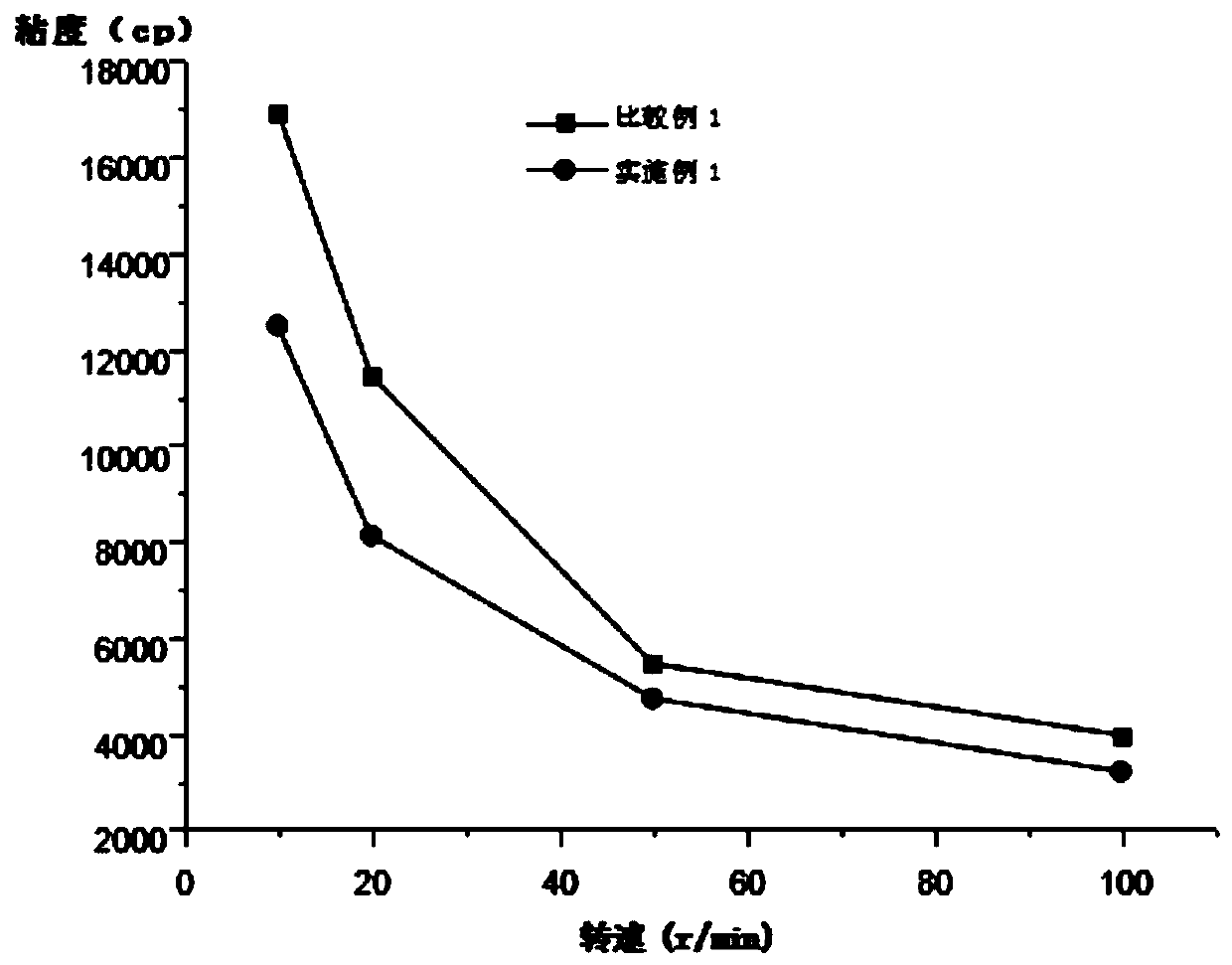

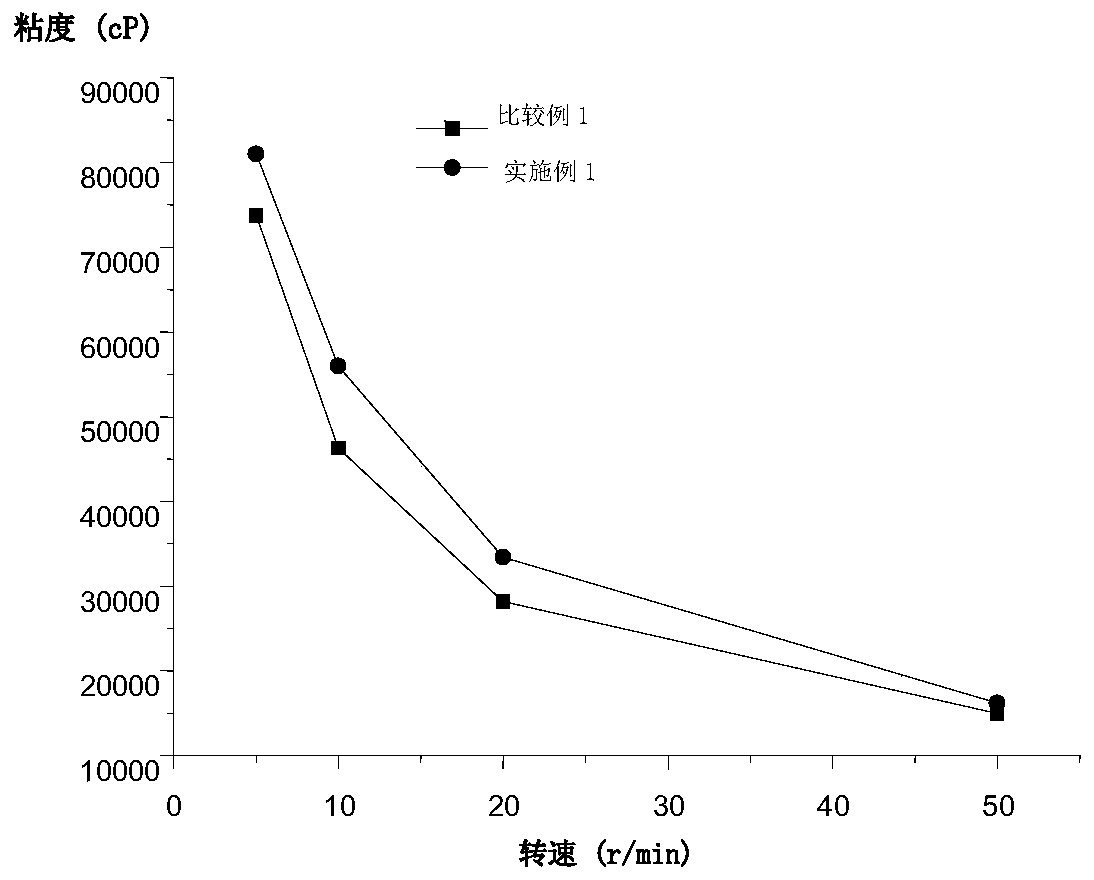

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com